Novel wire conveying device for numerically-controlled wire cutting electrical discharge machine

A technology of wire cutting and spark machine, applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems affecting the cutting processing accuracy, and achieve the effect of improving utilization rate, reducing vibration and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

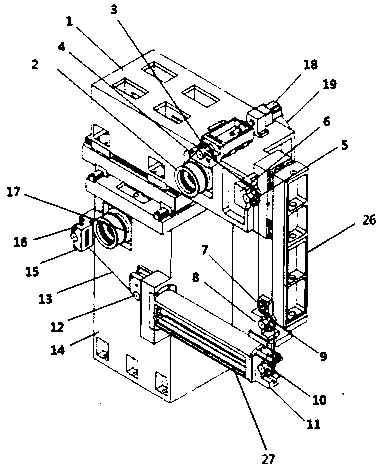

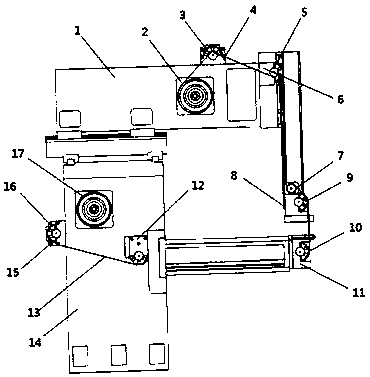

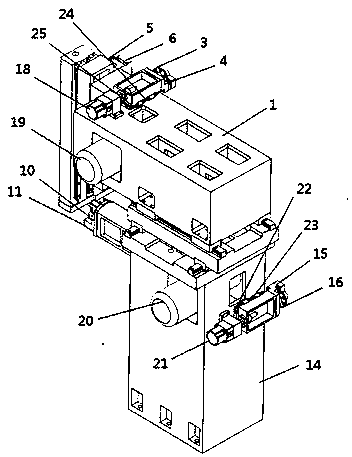

[0022] Example: such as Figure 1-3 As shown, the present invention provides a novel CNC wire-cutting spark machine wire transport device, comprising an upper frame 1 and a lower frame 14 stacked up and down, and an upper wire drum 2 and a lower wire drum are respectively installed on the upper and lower frames 17. The upper wire drum 2 and the lower wire drum 17 are located on the same plane of the frame, connected by molybdenum wire 13, and move synchronously under the drive of the motor; the two ends of the molybdenum wire 13 are respectively wound on the upper and lower wire drums The molybdenum wire 13 is connected to the upper wire wheel 3 after bypassing the upper wire drum 2, and is connected to the fixed guide wheel 5 through the upper wire wheel 3; On the wheel seat frame 4, the upper fixed guide wheel 5 is installed on the upper fixed wheel seat frame 6 at the top of the upper wire frame 26 on the side of the upper and lower frame; The bridge guide wheel 7 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com