Mechanical system of high-speed test board for automobile transmission

A technology of automobile transmission and mechanical system, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of unsatisfactory equipment reliability, difficult equipment adjustment, and large vibration of mechanical system, so as to achieve fast and convenient adjustment, improve test efficiency, The effect of convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

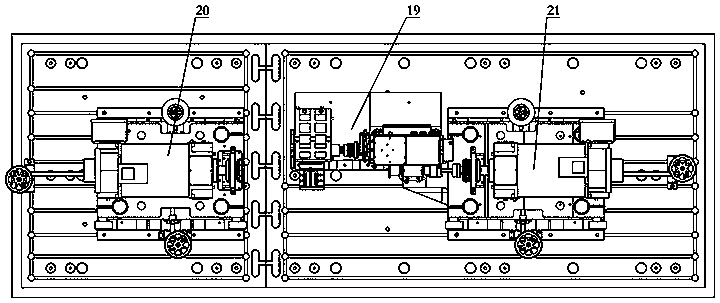

[0015] Such as Figure 1 As shown, a mechanical system of a high-speed test bench for an automobile transmission includes: a driving system 19, a left loading system 20, and a right loading system 21. mobile adjustments. The left loading system 20 can be adjusted in height, left and right, and front and rear, so as to meet the change of the center distance between the input and output shafts of different transmissions, and the change of the length of the half shaft. The right loading system 21 can be adjusted in height, left and right, and front and rear, so as to meet the change of the center distance between the input and output shafts of different transmissions, and the change of the length of the half shaft.

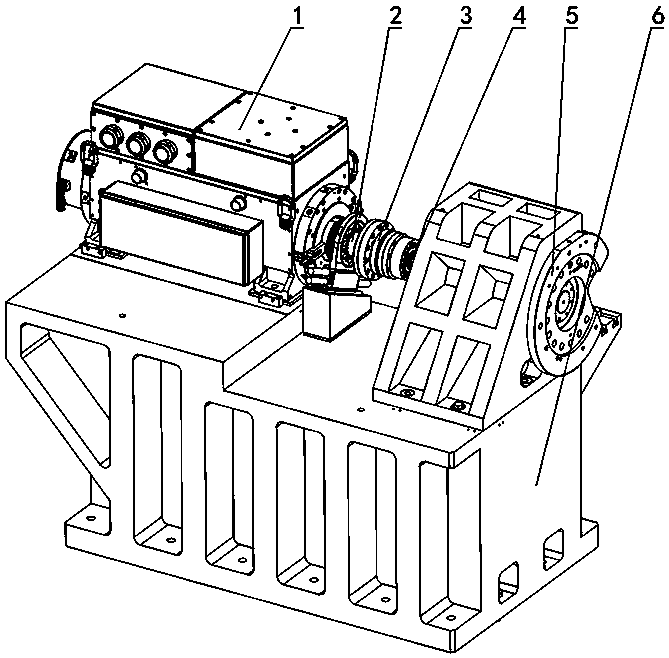

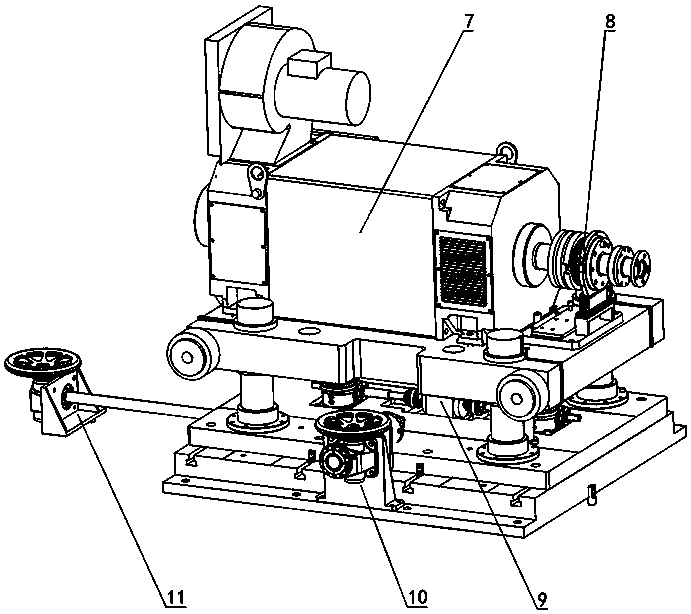

[0016] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com