Movable hydraulic lifting scissors type arm frame tool car

A technology of hydraulic lifting and scissor arm frame, applied in the direction of lifting frame, lifting device, etc., can solve the problems of inconvenient assembly of large-quality parts, high degree of electrification, and high maintenance cost, and achieve high cost performance, convenient operation and maintenance, and use low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

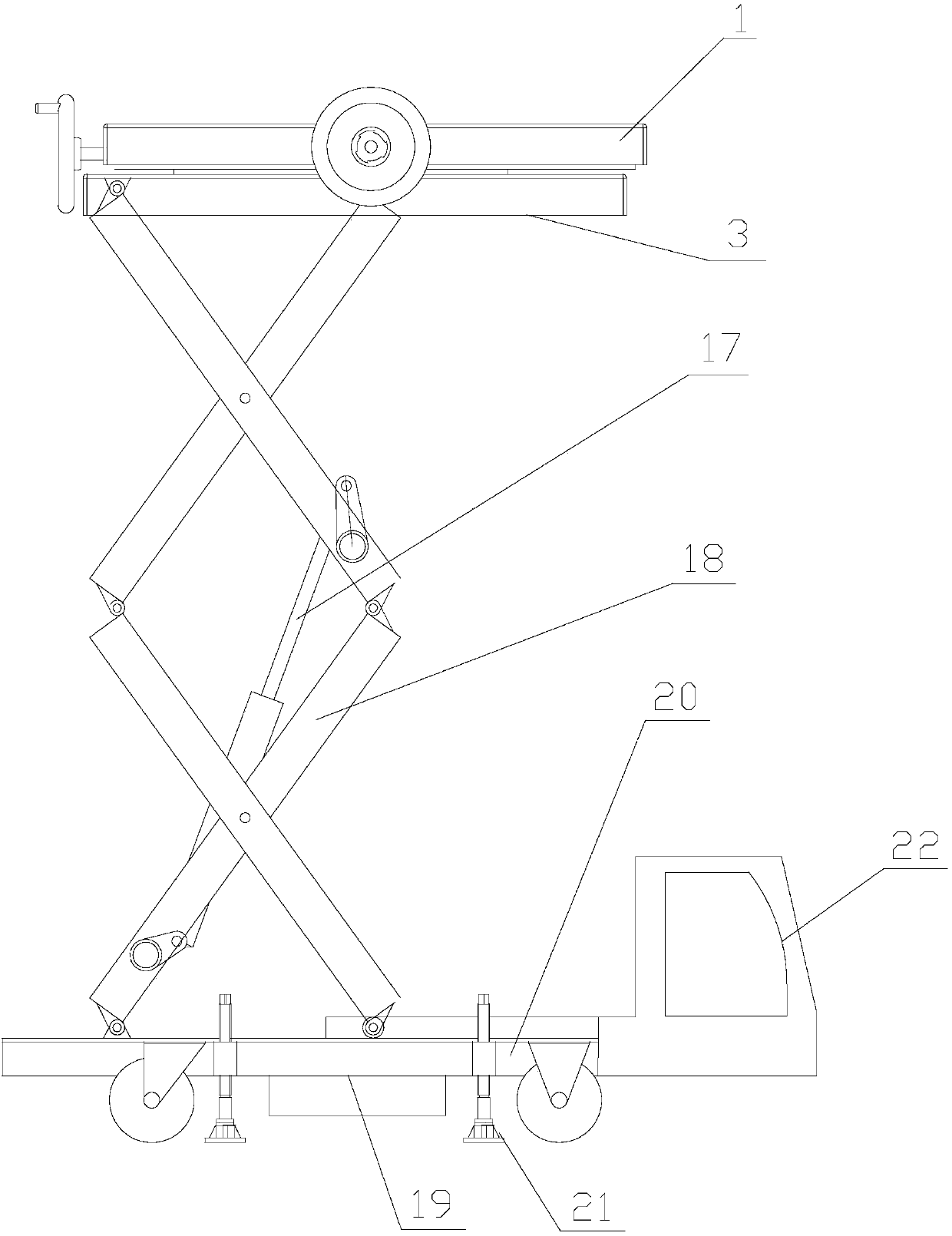

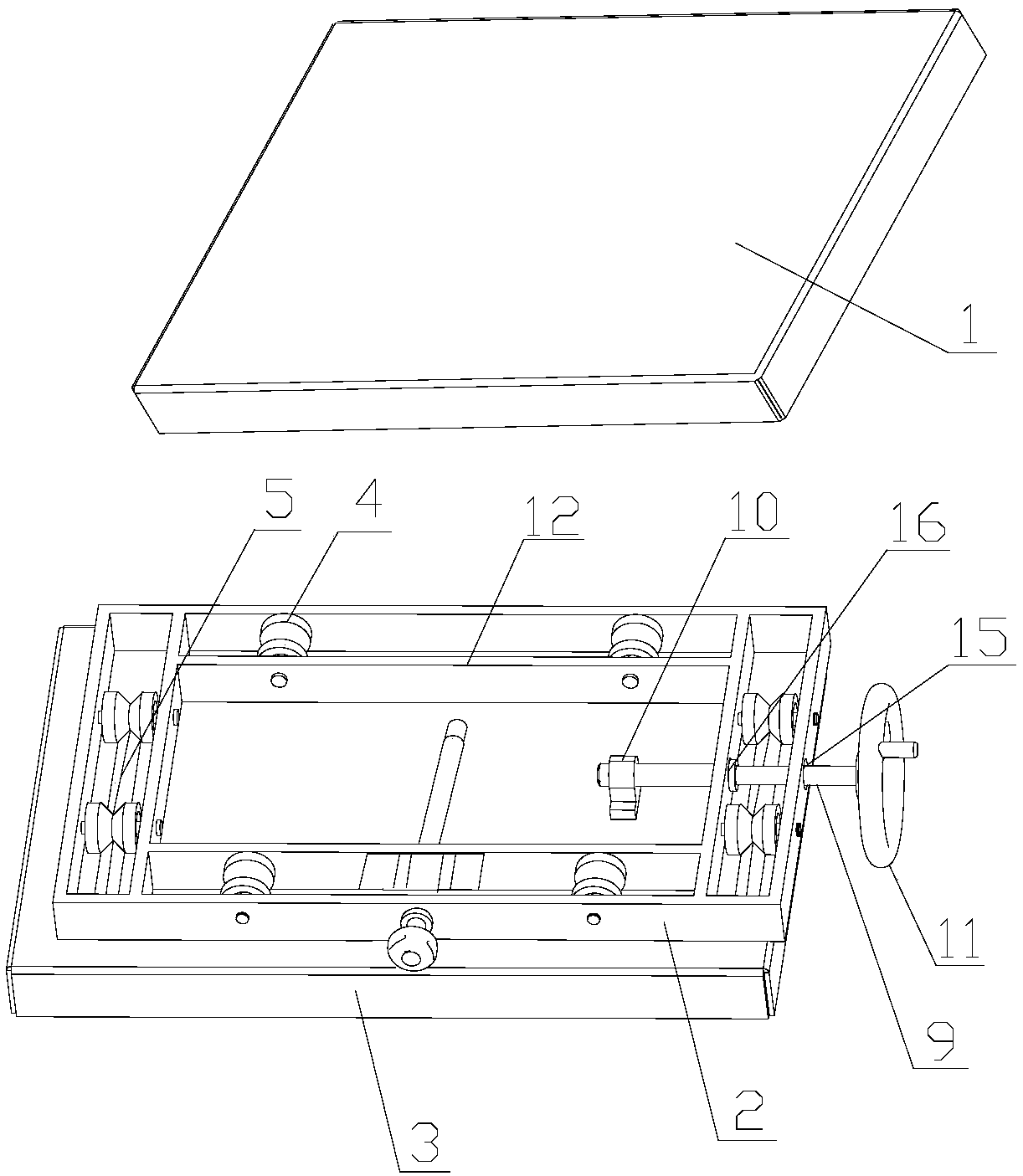

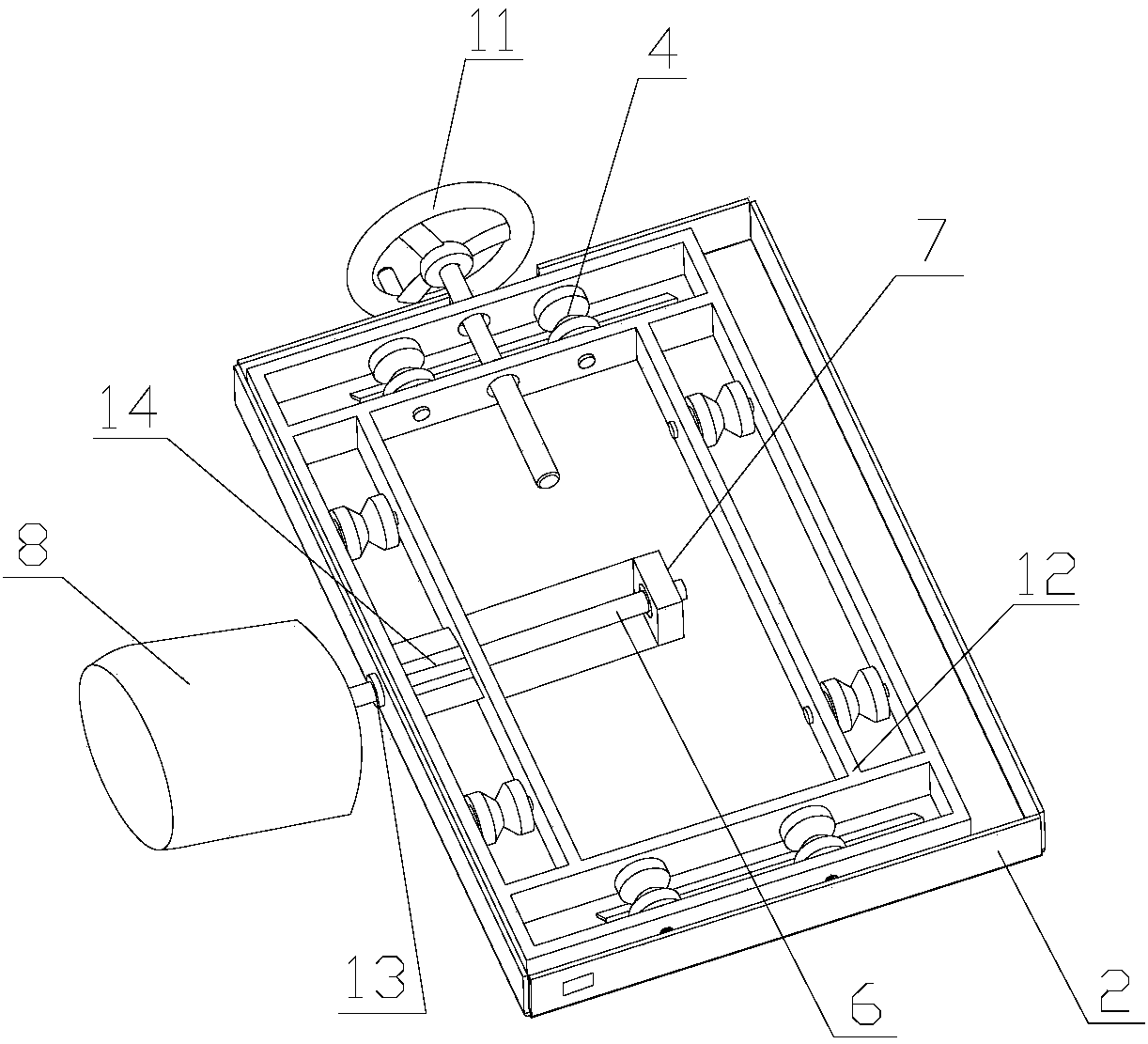

[0016] Such as Figure 1 to Figure 3 As shown, the mobile hydraulic lifting scissor arm frame tool cart includes a control room 22, a chassis 20 and a hydraulic pump station 19, the chassis 20 is provided with traveling wheels and liftable support legs 21, and the chassis 20 is provided with a hydraulic pump station 19 and the scissor arm frame 18 that can be lifted, the scissor arm frame 18 is provided with the lifting hydraulic cylinder 17, and the upper end of the scissor arm frame 18 is provided with a working platform. The work platform is provided with an upper deck 1, a workbench 2 and a lower deck 3 of a rectangular or square structure, and the workbench 2 is arranged between the upper deck 1 and the lower deck 3 and is connected to each other; the control room 22 is provided with a direction machine and a motor. control device, the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com