Concrete and preparation technology thereof

A technology for concrete and recycled aggregates, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Increase in properties, improve durability, and improve the effect of large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

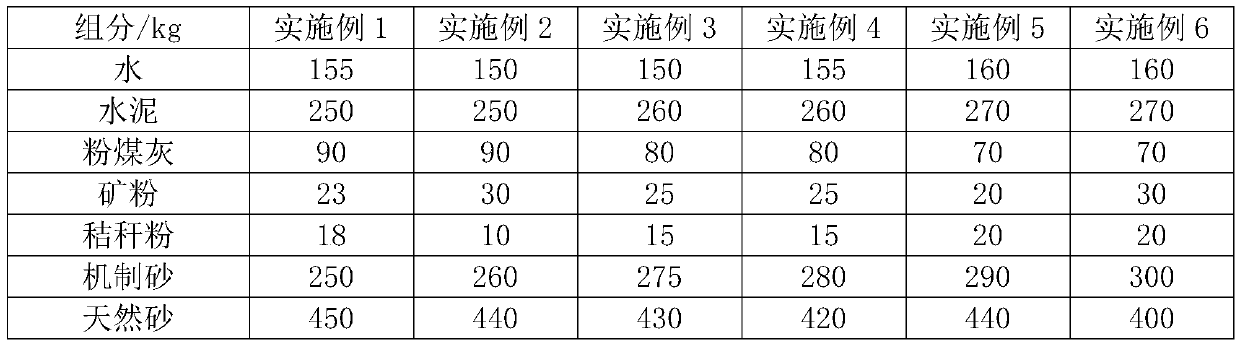

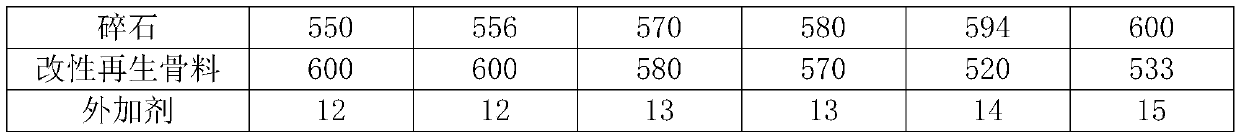

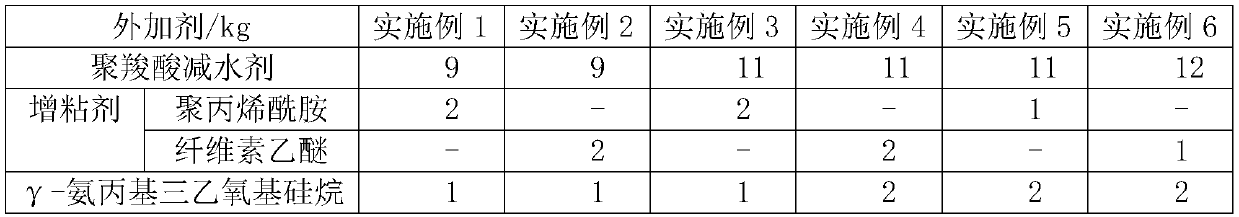

Method used

Image

Examples

preparation example 1

[0045] Modification steps of modified recycled aggregate: S1. Pre-soaking recycled aggregate: soak 1000kg recycled aggregate with 1% acetic acid for 2 hours to obtain the first product;

[0046] S2. After washing the first product with water, add it to the slurry prepared by 127kg of water, 6kg of calcium sulfoaluminate, 254kg of cement, 32kg of fly ash and 32kg of straw powder and wrap it into a second product with a thickness of 1-2mm. After the product is coagulated, a modified recycled aggregate is obtained.

preparation example 2

[0048] Modification steps of modified recycled aggregate: S1. Pre-soaking recycled aggregate: soak 1000kg recycled aggregate with 2% acetic acid for 1.8h to obtain the first product;

[0049] S2. After washing the first product with water, add it to the slurry prepared by 127 kg of water, 6 kg of calcium sulfoaluminate, 190 kg of cement, 63 kg of fly ash and 63 kg of straw powder and wrap it into a second product with a thickness of 1-2 mm. After the product is coagulated, a modified recycled aggregate is obtained.

preparation example 3

[0051] Modification steps of modified recycled aggregate: S1. Pre-soaking recycled aggregate: soak 1000kg recycled aggregate with 2% acetic acid for 1.5h to obtain the first product;

[0052] S2. After washing the first product with water, add it to the slurry prepared by 125 kg of water, 13 kg of calcium sulfoaluminate, 125 kg of cement, 94 kg of fly ash and 94 kg of straw powder and wrap it into a second product with a thickness of 1-2mm. After the product is coagulated, a modified recycled aggregate is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com