Plant self-cleaning and formaldehyde removing essence, preparation method and self-cleaning coating

An essence and self-cleaning technology, which is applied in the fields of plant self-cleaning and aldehyde-removing essence and self-cleaning coating, can solve people's health problems, cleaning laborious and other problems, and achieve good market prospects and good effect of formaldehyde removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

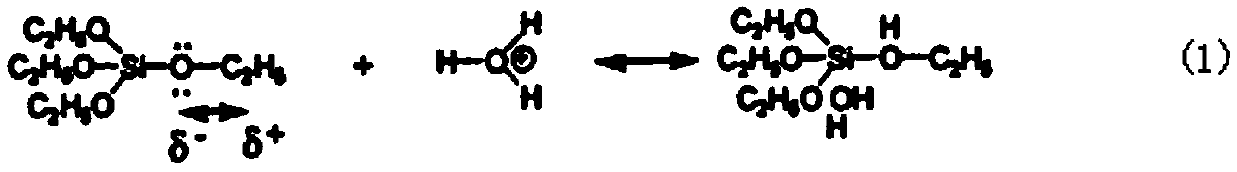

Method used

Image

Examples

Embodiment 1

[0073] (1) Weigh 72 parts by weight of water.

[0074] Adjust the pH of the water to 5.

[0075] (2) As a plant extract, weigh 10 parts by weight of tea polyphenols.

[0076] (3) Weighing 18 parts by weight of the chain nano-silica precursor.

[0077] (4) Weigh 0.2 parts by weight of nano titanium dioxide.

[0078] Specifically, 6 parts by weight of methyltriethoxysilane, 5 parts by weight of ethyl orthosilicate and 7 parts by weight of γ-glycidyloxypropyltrimethoxysilane were weighed.

[0079] (5) Preparation of plant self-cleaning and aldehyde-removing essence.

[0080] The above-mentioned chain-like nano-silica precursor, tea polyphenols, nano-titanium dioxide and water are evenly mixed to obtain a plant self-cleaning and aldehyde-removing essence.

[0081] The plant self-cleaning and aldehyde-removing essence is sprayed on the surface of the wooden sample, and a self-cleaning coating is formed after natural air-drying. The sample is tested for graffiti effect, and the ...

Embodiment 2

[0083] (1) Weigh 65 parts by weight of water.

[0084] Adjust the pH of the water to 6.

[0085] (2) As a plant extract, weigh 5 parts by weight of thujone.

[0086] (3) Weighing 30 parts by weight of the chain nano-silica precursor.

[0087] (4) Weigh 0.1 parts by weight of nano-titanium dioxide.

[0088] Specifically, the chain-shaped nano-silica precursor includes methyltriethoxysilane and ethyl orthosilicate.

[0089] (5) Preparation of plant self-cleaning and aldehyde-removing essence.

[0090] The above-mentioned chain-like nano-silica precursor, nano-titanium dioxide, thujone and water are uniformly mixed to obtain a plant self-cleaning and aldehyde-removing essence.

[0091] The plant self-cleaning and aldehyde-removing essence is sprayed on the surface of the leather sample, and a self-cleaning coating is formed after natural air drying. The sample is tested for graffiti, and the self-cleaning and anti-graffiti rate of the self-cleaning coating is 98%. Better ref...

Embodiment 3

[0093] (1) Weigh 80 parts by weight of water.

[0094] Adjust the pH of the water to 5.

[0095] (2) As a plant extract, weigh 15 parts by weight of a mixture of tea polyphenols and thujone.

[0096] (3) Weighing 5 parts by weight of the chain nano-silica precursor.

[0097] (4) Weigh 0.3 parts by weight of nano-titanium dioxide. Specifically, 6 parts by weight of methyltriethoxysilane, 5 parts by weight of ethyl orthosilicate and 7 parts by weight of γ-glycidyloxypropyltrimethoxysilane were weighed.

[0098] (5) Preparation of plant self-cleaning and aldehyde-removing essence.

[0099] Mix the above-mentioned chain nano-silica precursor, tea polyphenols, nano-titanium dioxide, and thujone mixture with water to obtain a plant self-cleaning and aldehyde-removing essence.

[0100] The plant self-cleaning and aldehyde-removing essence is sprayed on the surface of the metal sample, and a self-cleaning coating is formed after natural air drying. The sample is tested for graffit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com