Preparation method of thermal insulation flocked yarn

A yarn and flocking technology is applied in the field of preparation of heat-insulating flocking yarns, which can solve the problems of missing coating, affecting the quality of flocking, thick coating, etc., so as to ensure quality, improve production efficiency, and save time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

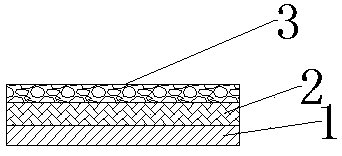

Image

Examples

Embodiment

[0030] (1) Feeding and feeding: 60 groups of spindles are pre-loaded into the creel device, and each group of yarns passes through their corresponding multi-component yarn rings to ensure the running path of the yarns, so that the yarns will not be separated from each other. The entanglement will affect the production of yarn. After the yarn is divided, the yarn group is connected to the clamping device, and the yarn group is adjusted to clamp the yarn group at an appropriate position. The yarn group then passes through the yarn tension balancer to adjust the yarn tension to complete the feeding. Prepare;

[0031] (2) Pretreatment and decontamination: the yarn group is immersed in the pretreatment solution through the power roller, and the bubbles generated by the 2400W ultrasonic generator are used to assist the pretreatment solution to clean the dirt on the yarn and improve the cleaning efficiency. The cleaning temperature is 50~80℃ , and then the yarn group passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com