Gear pair of fuel oil gear pump

A gear pair and gear pump technology, applied in the field of gear pairs, can solve problems such as complex gear shapes, and achieve the effects of strong wear resistance, high reliability, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A gear pair of a fuel gear pump is provided, the number of teeth Z, modulus and pressure angle α of the driving gear and the driven gear in the gear pair are the same, and the coincidence degree ε of the gear pair satisfies the relational expression:

[0016] ε=Z(tanα d -tanα) / π,

[0017] Among them, the addendum circle pressure angle

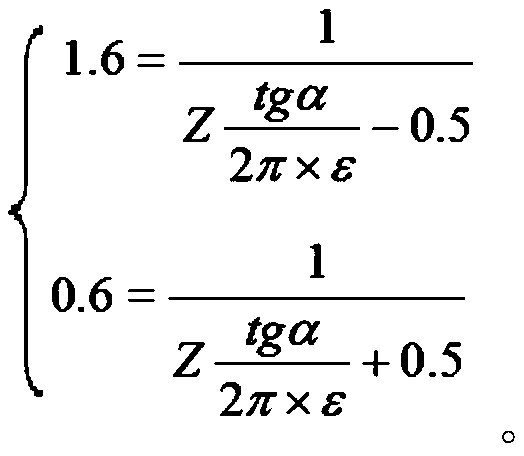

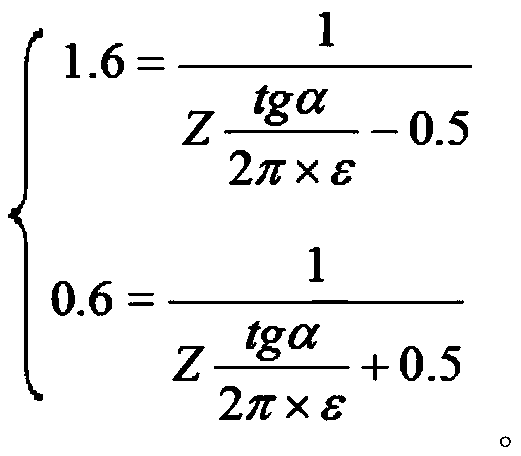

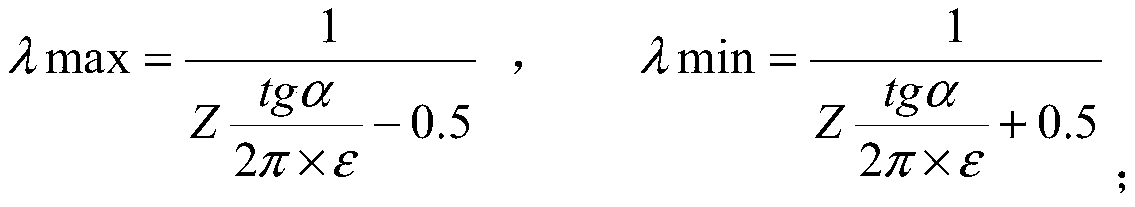

[0018] In addition, in the gear pair, the number of teeth Z, the pressure angle α, and the coincidence degree ε also satisfy the following relationship:

[0019]

[0020] The material of the driving gear and the driven gear is AHP10V powder metallurgy tool steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com