A cloth defect detection method based on Fourier transform and image morphology

A technology of Fourier transform and image morphology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of single type of defect recognition and poor cloth detection effect, so as to improve efficiency and enhance detection robustness. The effect of reducing the impact of false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

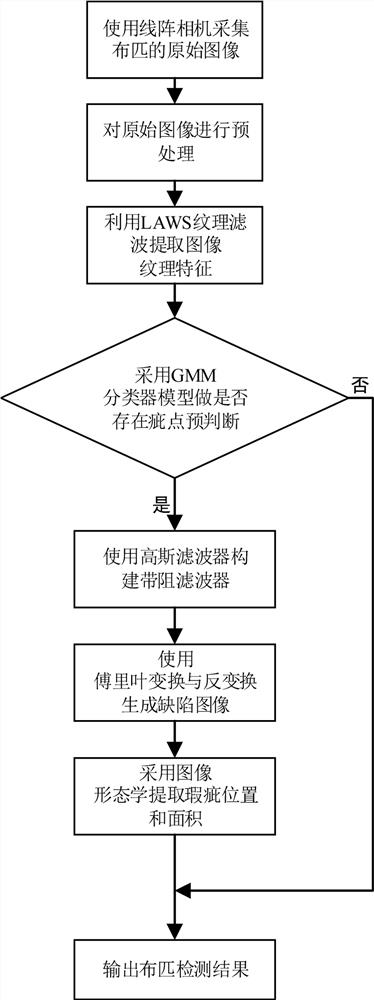

[0054] Such as figure 1 A cloth defect detection method based on Fourier transform and image morphology is shown, including the following steps:

[0055] (1) Use a line array camera to collect the original image of the cloth;

[0056] (2) Preprocessing the original image;

[0057] (3) Using LAWS texture filtering to extract image texture features;

[0058] (4) Using the GMM classifier model for pre-discrimination of defects;

[0059] (5) Use a Gaussian filter to construct a band-stop filter;

[0060] (6) Fourier transform and inverse transform to generate defect images;

[0061] (7) Using image morphology to extract the position and area of cloth defects;

[0062] (8) Output the cloth detection result.

[0063] Step (1) specifically includes:

[0064] It is required that the dpi of the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com