A kind of synthetic method of sandwich structure cofe@c/graphene electromagnetic wave absorbing material

A technology of absorbing materials and synthesis methods, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems that are difficult to put into production and large-scale use, the application range is not wide, and magnetic metals are easy to be oxidized, so as to prevent oxidation and be operable Strong and reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

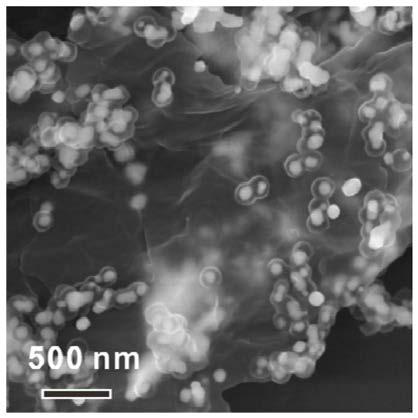

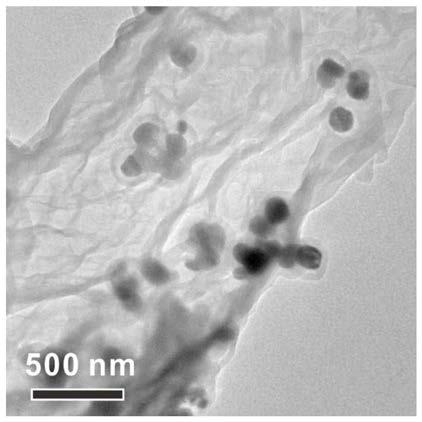

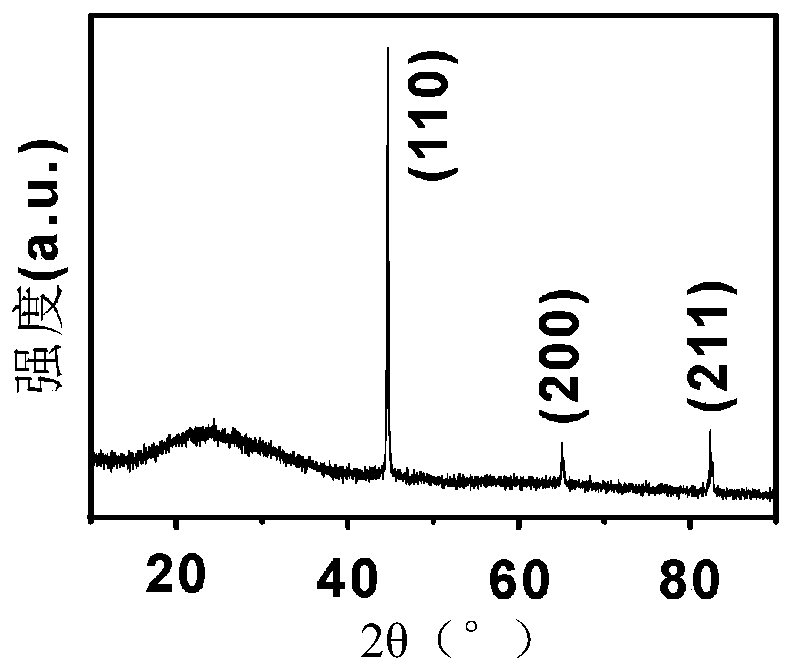

Image

Examples

Embodiment 1

[0029] (1) Add ferric chloride, cobalt acetate and ammonium acetate to 60ml of ethylene glycol and stir to dissolve in 100ml of PTFE lining. The mass ratio of ferric chloride and cobalt acetate is 2:1, ammonium acetate The addition amount is 50 mg, and the mass ratio of ferric chloride, cobalt acetate and ammonium acetate is 0.54:0.25:0.50. The mixed solution was stirred at room temperature for 3 h to ensure complete dissolution and uniform mixing. Put the polytetrafluoroethylene lining into the reaction kettle, screw it tightly, and finally place it in the oven, and react at a constant temperature of 200 ° C for more than 5 hours.

[0030] (2) After the reaction, the reaction solution was cooled to room temperature, and the product was separated with a magnet. The obtained product was washed with water, washed with ethanol ultrasonically for several times, and dried in vacuum to obtain CoFe 2 o 4 powder.

[0031] (3) 120mgCoFe 2 o 4 The powder and 1 mg of commercial grap...

Embodiment 2

[0035] (1) Add ferric chloride, cobalt acetate and ammonium acetate to 60ml of ethylene glycol and stir to dissolve in 100ml of PTFE lining. The mass ratio of ferric chloride and cobalt acetate is 1:1, ammonium acetate The addition amount is 50 mg, and the mass ratio of ferric chloride, cobalt acetate and ammonium acetate is 0.27:0.25:0.50. The mixed solution was stirred at room temperature for 3 h to ensure complete dissolution and uniform mixing. Put the polytetrafluoroethylene lining into the reaction kettle, screw it tightly, and finally place it in the oven, and react at a constant temperature of 200 ° C for more than 5 hours.

[0036] (2) After the reaction, cool the reaction solution to room temperature, separate the product with a magnet, wash the obtained product with water, then ultrasonically wash it with ethanol several times, and dry it in vacuum to obtain cobalt ferrite powder.

[0037] (3) Disperse 120 mg of cobalt ferrite powder and 1 mg of commercial graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap