Timing drive system for inhibiting multi-drum threshing vibration and grain combine harvester

A transmission system, multi-drum technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of unbalanced vibration and the continuous beating of the axis, achieve accurate and stable rotation speed, suppress threshing vibration, and suppress threshing vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

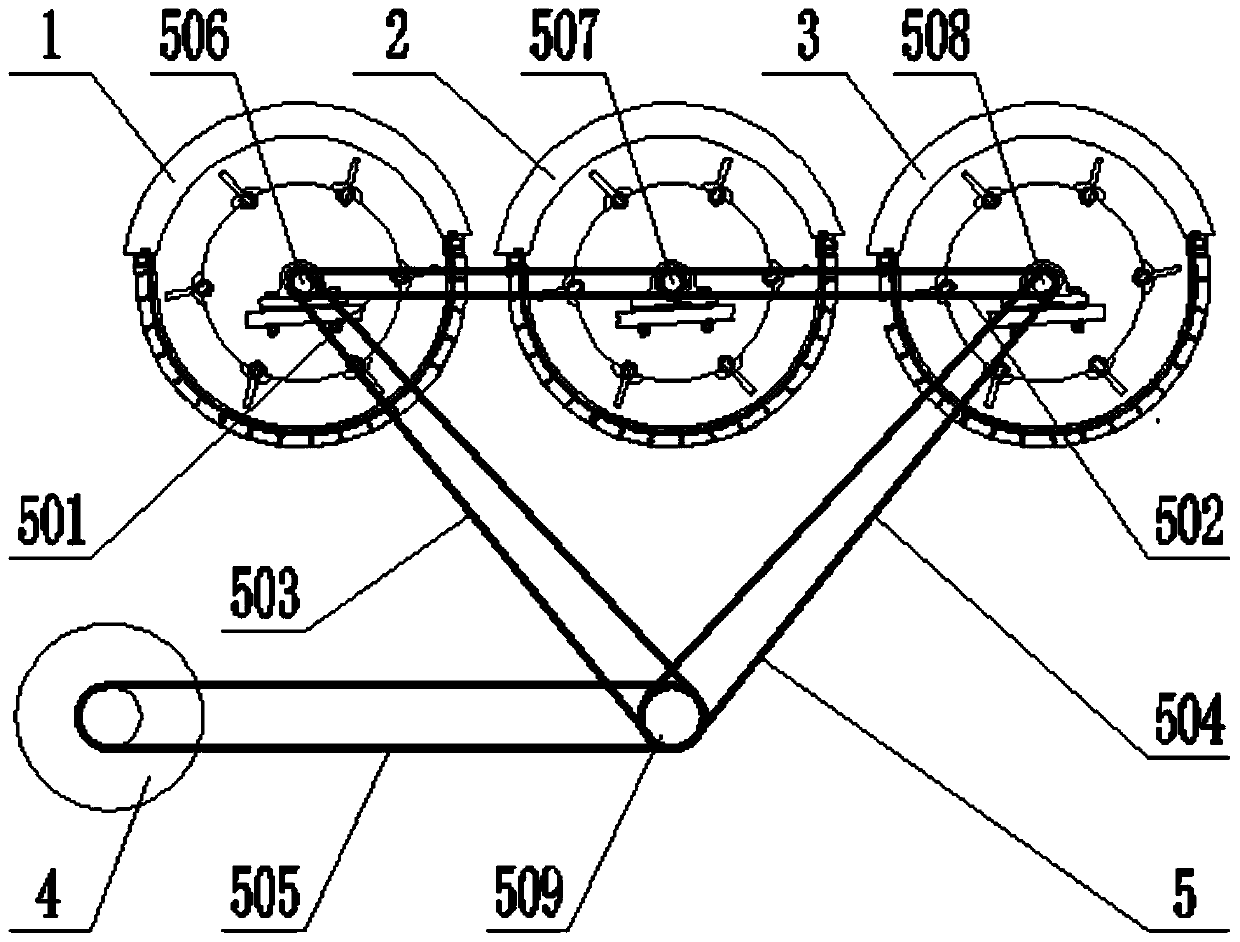

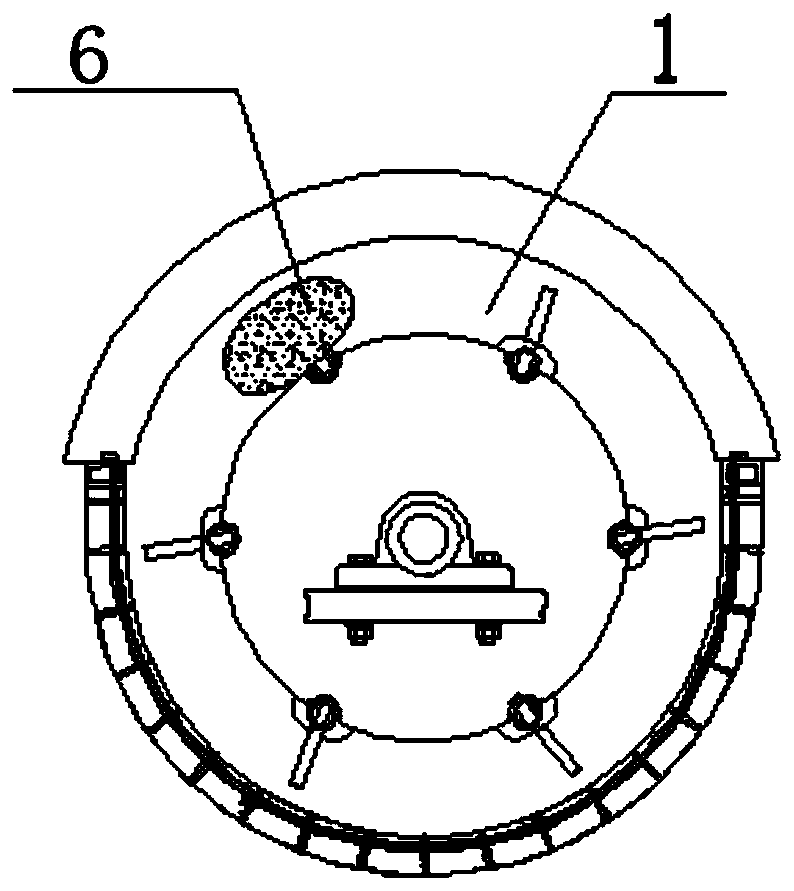

[0073] A timing transmission system for suppressing multi-cylinder threshing vibration, comprising at least two coaxially installed threshing cylinders, a motor 4 and a timing transmission mechanism 5; the timing transmission mechanism 5 connects the rotating shafts of each threshing cylinder to the engine 4 , the power of the engine 4 is transmitted to the rotating shafts of each threshing cylinder through the timing transmission mechanism 5, so that all the threshing cylinders rotate synchronously.

[0074] The timing transmission mechanism 5 includes several toothed V-belts and timing gears; the toothed V-belts connect the rotating shafts of each threshing cylinder with the engine 4 through the timing gears.

[0075] The speed relationship of the threshing drum should satisfy n 1 =n 2 =n 3 ….=n i ; The mass relation of the material in the threshing drum is m 1 >m 2 >m 3 …>m i ; In order to guarantee that the centrifugal force relation that material produces in each ...

Embodiment 2

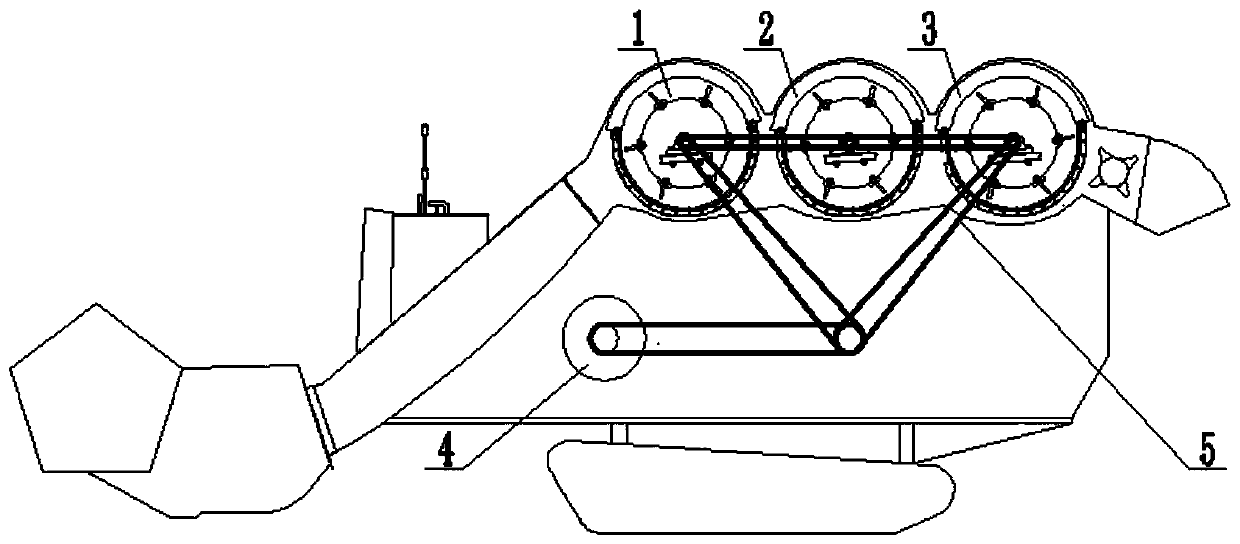

[0089] Such as figure 1 As shown, the difference between the present embodiment 2 and the embodiment 1 mainly lies in that the quantity of the threshing drums of the timing transmission system for suppressing the multi-drum threshing vibration described in the present embodiment 2 is 3, including the threshing drum I1, the threshing drum II2 and the threshing drum II2. Threshing drum III3. The threshing drum I1 is located on the left side of the threshing drum II2; the threshing drum III3 is located on the right side of the threshing drum II2; the engine 4 is located at the left bottom of the threshing drum I1; Cylinder III3 is connected with engine 4 to ensure that each threshing cylinder rotates synchronously without deviation in rotation angle. The timing transmission system cancels the eccentric vibrations on threshing cylinder I1, threshing cylinder II2 and threshing cylinder III3.

[0090] Such as figure 2As shown, the timing drive system 5 includes a toothed V-belt I...

Embodiment 3

[0127] A combine harvester includes the timing transmission system for suppressing multi-drum threshing vibration described in Embodiment 1 or Embodiment 2, so it has the beneficial effects described in Embodiments 1 and 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com