Bone tissue engineering stent

A bone tissue engineering and metal-based technology, which is applied in the field of degradable bone tissue engineering scaffolds, can solve the problems of influence on mechanical properties, limited improvement of mechanical properties of scaffolds, difficulty in meeting mechanical performance requirements of bone tissue scaffolds, etc., and achieve good mechanical properties , improve mechanical properties, and repair large bone defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

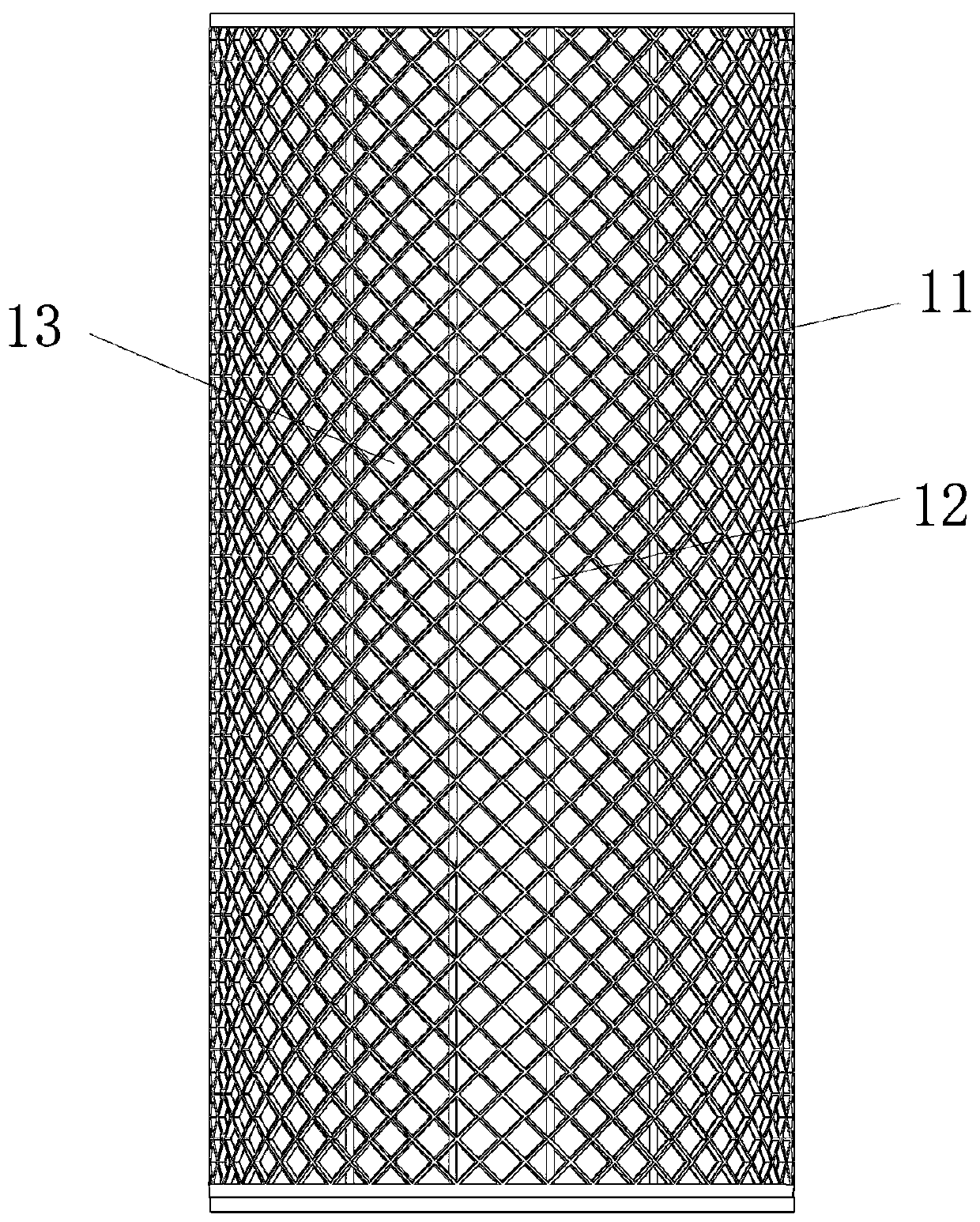

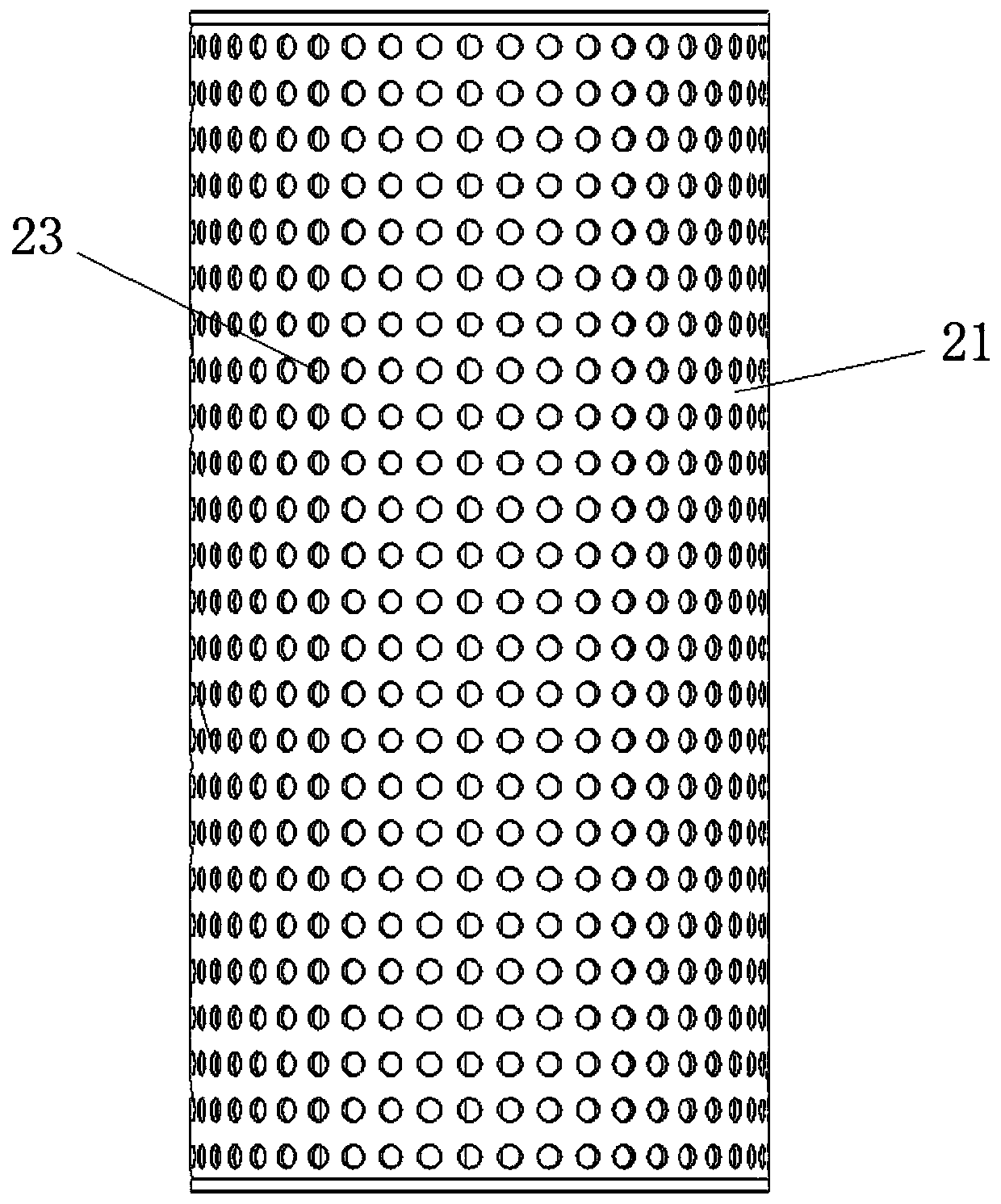

[0054] A preferred structure of the bone tissue engineering scaffold of the present invention is as follows: figure 1 As shown, its grid-shaped support 11 is cylindrical, with a diameter of 1-5cm and a height of 2-10cm. There are four cylindrical support columns 12 inside the support, with a diameter of 0.3-0.8mm, more preferably 0.4 -0.6mm, the positions of the supporting columns can be arranged symmetrically or arbitrarily, the shape of the grid 13 of the cylindrical support is square, the diagonal length of the grid is 0.5-2mm, and its size is based on the porous zinc-based metal ball and β - It is desirable that TCP particles do not come out. According to actual needs, the internal support column 12 in this embodiment may also be absent. Further, the hollow grid-shaped bracket 11 and its internal support column 12 may be made of pure titanium or titanium alloy with excellent mechanical properties, but they can also be It can be made of degradable zinc-based metal material...

Embodiment 2

[0060] For a large bone defect of the femoral shaft with a length of about 5 cm, a cylindrical mesh-like scaffold was first designed according to the shape of the bone defect, and the outer layer of the scaffold and the inner support column were prepared with TC4 titanium alloy as the raw material. The scaffold was designed to be 3.5 cm in diameter and 5 cm in height. Sub-cylindrical, the grid holes of the bracket are designed as square or rhombus, with a long diameter of 0.5mm, or the grid holes are designed as circular, with a diameter of 0.5mm, and 4 supporting columns with a diameter of 0.5mm are arranged inside. Then select Zn-1Sr alloy (Sr1wt.%, ultimate tensile strength UTS=160MPa, yield strength YS=120MPa, elongation>30%) to prepare porous zinc-based solid metal balls, and the diameter of the metal balls is 0.5-5mm. The laser ablation method is used to drill holes on Zn-1Sr metal balls with a diameter of 0.2mm and a porosity of 60%-90%. Select commercially available β-T...

Embodiment 3

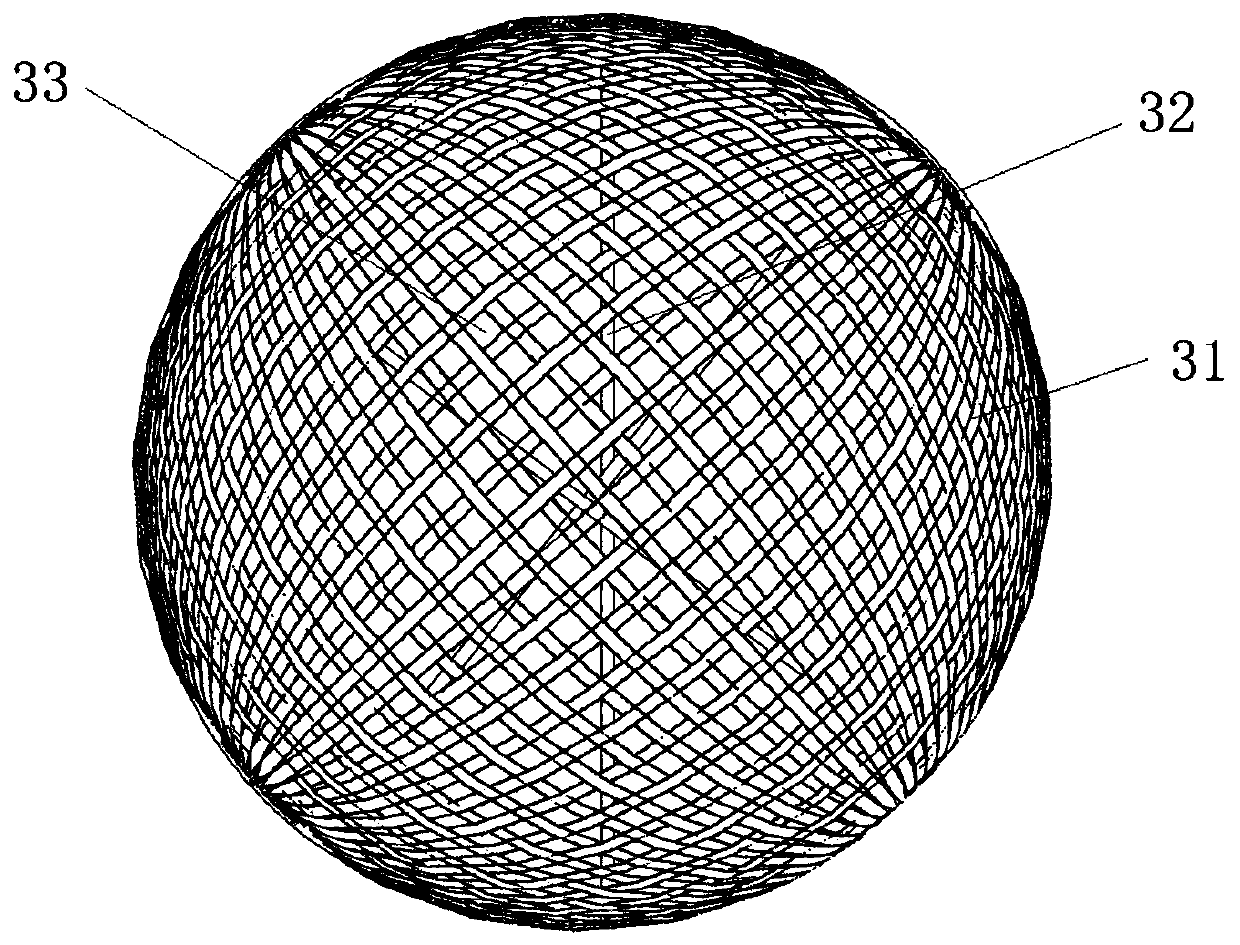

[0066] For a patient with proximal humeral tumor resection, a spherical bone defect with a diameter of about 3 cm remained after surgery. First, a spherical mesh scaffold was designed according to the shape of the bone defect, and Zn-0.8Li-0.1Mg alloy (Li0.8wt.%, Mg0.1wt.%, UTS=680MPa, YS=540MPa, elongation 10%) was used as the raw material. The design of the outer bracket and the inner support column, the size of the bracket is based on the shape of the paste and bone defect. The bracket is designed as a spherical bracket with a diameter of 3cm. The grid holes of the bracket are designed to be square or diamond-shaped with a long diameter of 0.5mm, or the grid holes are designed to be circular with a diameter of 0.5mm. There are three supports with a diameter of 0.5mm inside. column. Then choose Zn-0.8Mg alloy (Mg0.8wt.%, UTS=370MPa, YS=300MPa, elongation 10%) to prepare zinc-based metal balls (diameter ranging from 0.5-5mm). Use laser ablation to drill holes on Zn-0.8Mg me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap