Portable ultrasonic cleaner

An ultrasonic and portable technology, applied in the field of ultrasonic cleaning, can solve the problem of inability to fundamentally remove stains, and achieve the effects of easy storage for a long time, reduced length, and strong cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

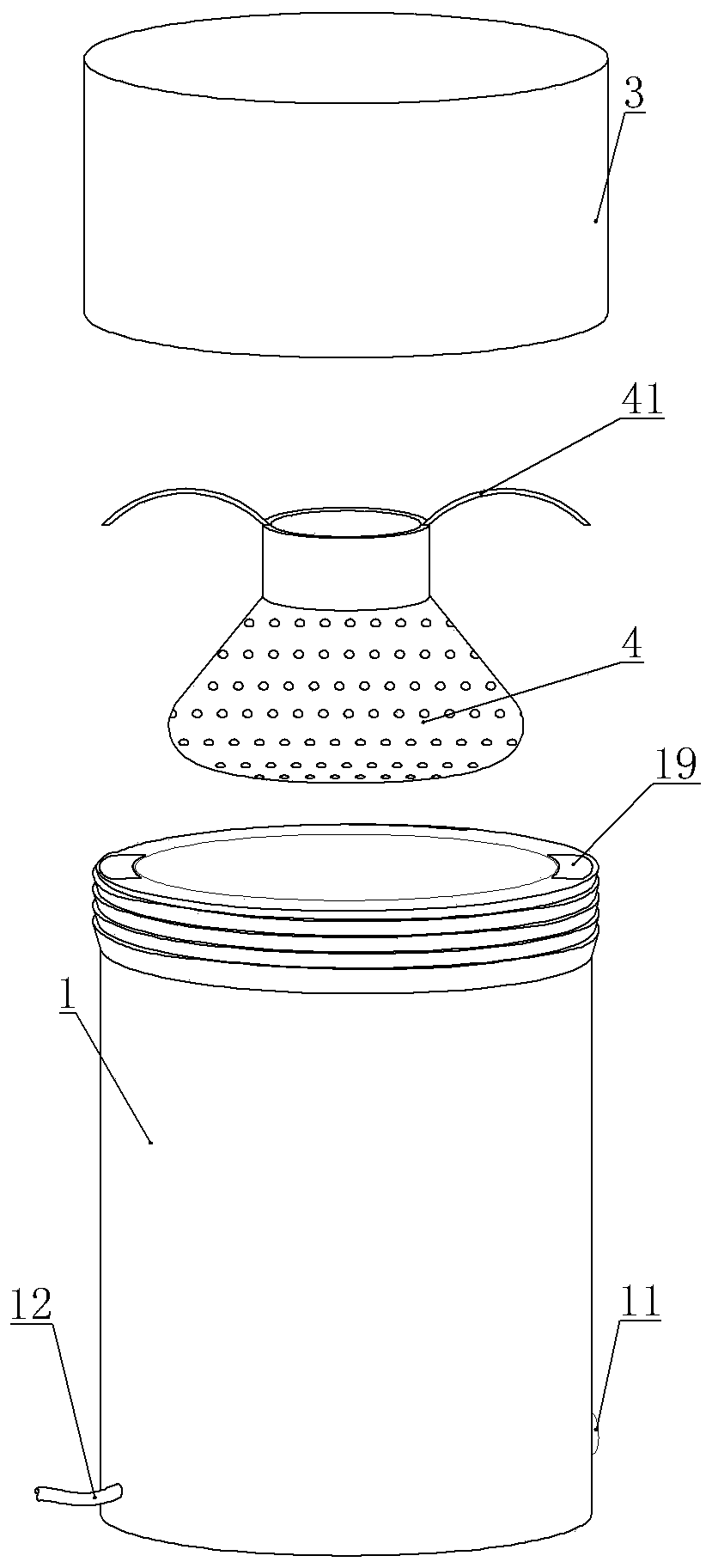

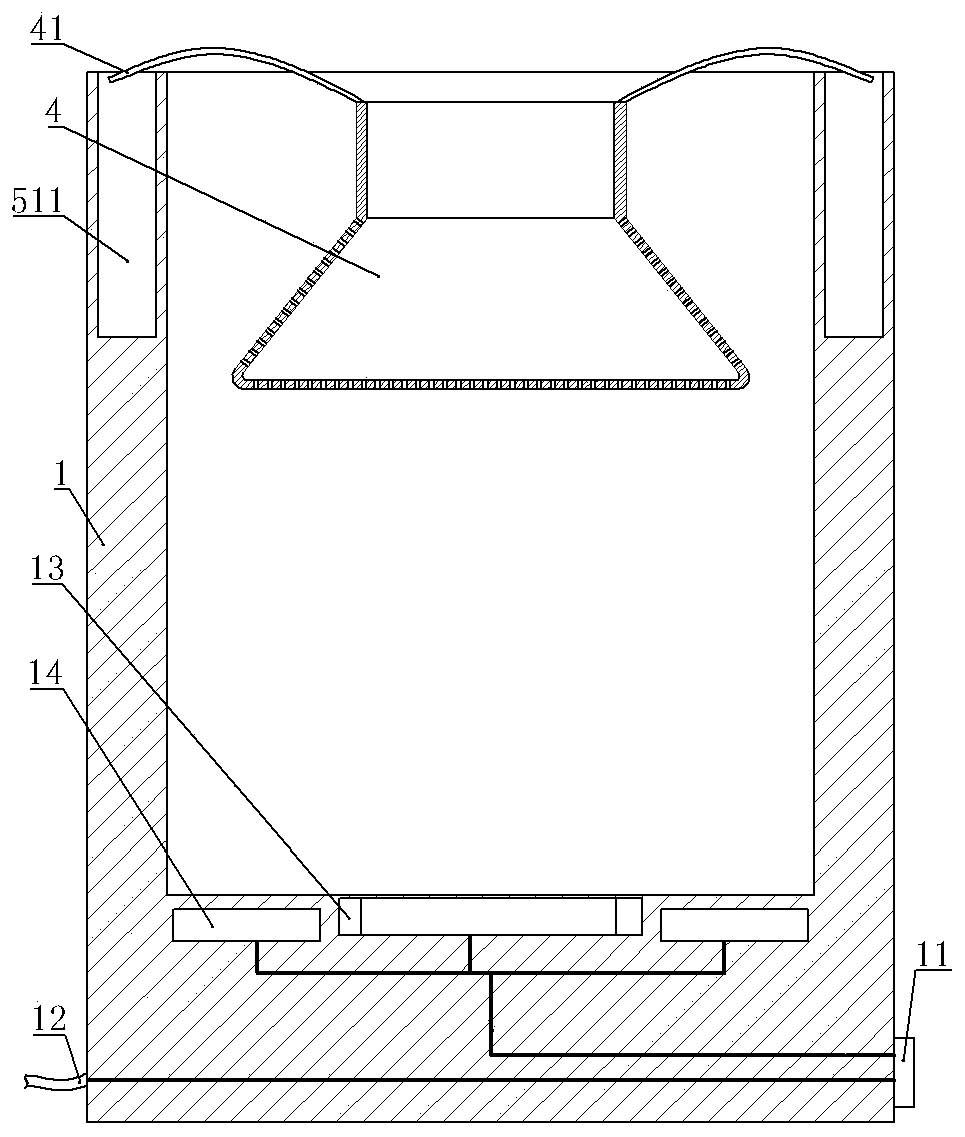

[0036] Embodiment 1 is basically as attached figure 1 with figure 2 Shown:

[0037] A portable ultrasonic cleaning machine includes a box body 1, a cleaning tank 4 and two ultrasonic generators 14. The box body 1 is provided with a cleaning chamber with an opening facing upwards, and the box body 1 is provided with a cover body 3 that closes the opening of the cleaning chamber. Specifically Yes, the cover body 3 can be directly covered on the box body 1, and the cover body 3 can be threadedly connected with the box body 1, and can also be hinged with the box body 1. The cover body 3 in this embodiment is connected with the box body by threaded connection body 1 connection. The cleaning tank 4 is located in the cleaning chamber, the top of the box body 1 is provided with two fixing tanks 19, the top of the cleaning tank 4 is provided with two folded parts 41, and the upper part of the folded parts 41 is folded outwards, and the cleaning tank 4 is put into the cleaning tank. ...

Embodiment 2

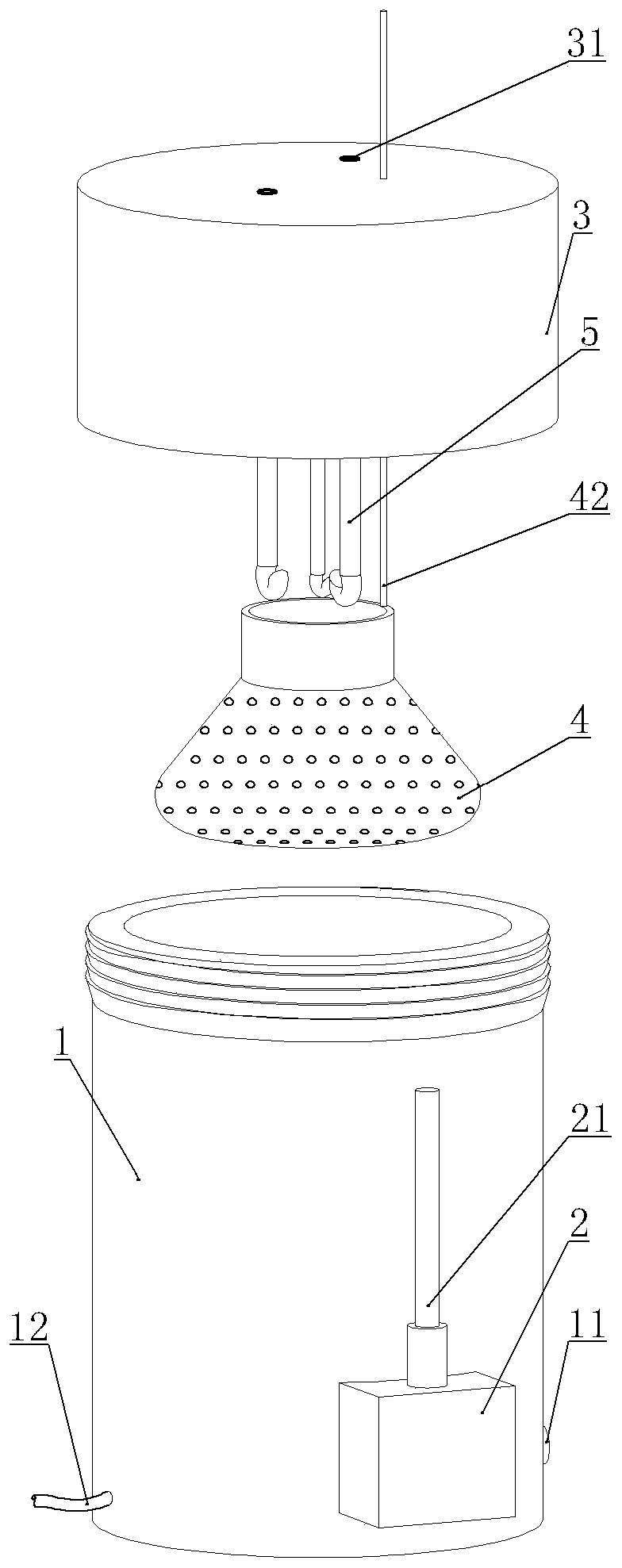

[0044] Embodiment 2 is basically as attached image 3 , Figure 4 with Figure 5 Shown:

[0045] The difference from Example 1 is that the top of the box body 1 in this implementation is not provided with a fixing groove, the top of the cleaning tank 4 is not provided with a folded part 41, and the cleaning chamber in this embodiment is vertically provided with a connecting rod 42 , the upper end of the connecting rod 42 runs through the cover body 3 and can slide relative to the cover body 3. The connecting rod 42 is covered with a tension ring 32. The tension ring 32 is located between the connecting rod 42 and the cover body 3, and is glued to the cover body 3. Therefore, when the connecting rod 42 is pulled up or down, the connecting rod 42 can slide relative to the cover body 3, and when the connecting rod 42 is loosened, the elastic force of the tension ring 32 exerts lateral pressure on the connecting rod 42 to generate sufficient frictional force Make the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com