Deslagging device for gas guide box

A gas guide box and slag removal technology, which is applied in the chemical industry, can solve the problems of ineffective transportation of hydrogen fluoride gas, easy to cause safety accidents, damage to enterprises and employees, etc., to reduce the impact of radial deformation, improve circulation, and improve The effect of force situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

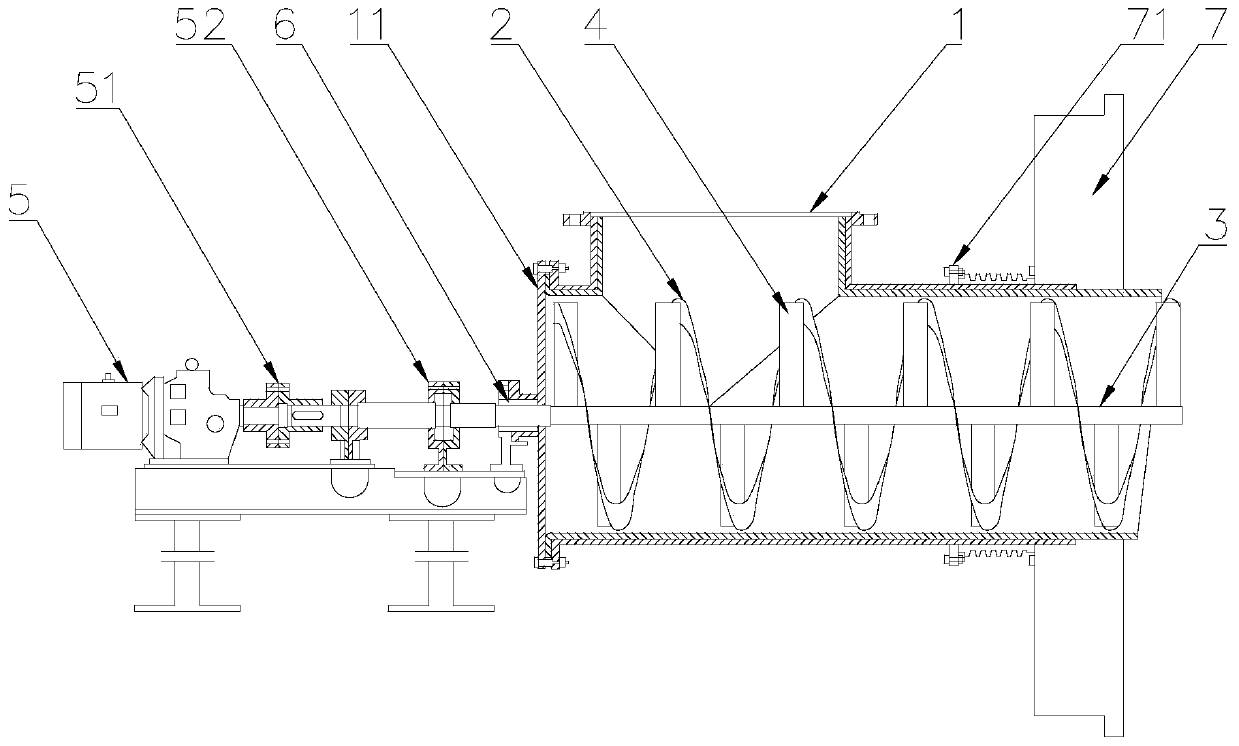

[0016] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0017] The most critical idea of the present invention is that the helical structure effectively reduces the space occupied by the slag removal device in the air guide box, ensures good gas circulation, and the helical structure has certain self-adaptability, which can improve the rotary slag removal. The stress of the belt during the process of scraping and conveying dust.

[0018] Please refer to figure 1 , a slag removal device for an air guide box, comprising a rotating slag removal belt arranged spirally along the gas conveying direction in the air guide box, and there is a gap between the rotating slag removal belt and the inner wall of the air guide box.

[0019] From the above description, it can be seen that the beneficial effect of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com