Online prediction method for future tool wearing capacity

A tool wear and prediction method technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., to achieve the effect of strong generalization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and embodiments.

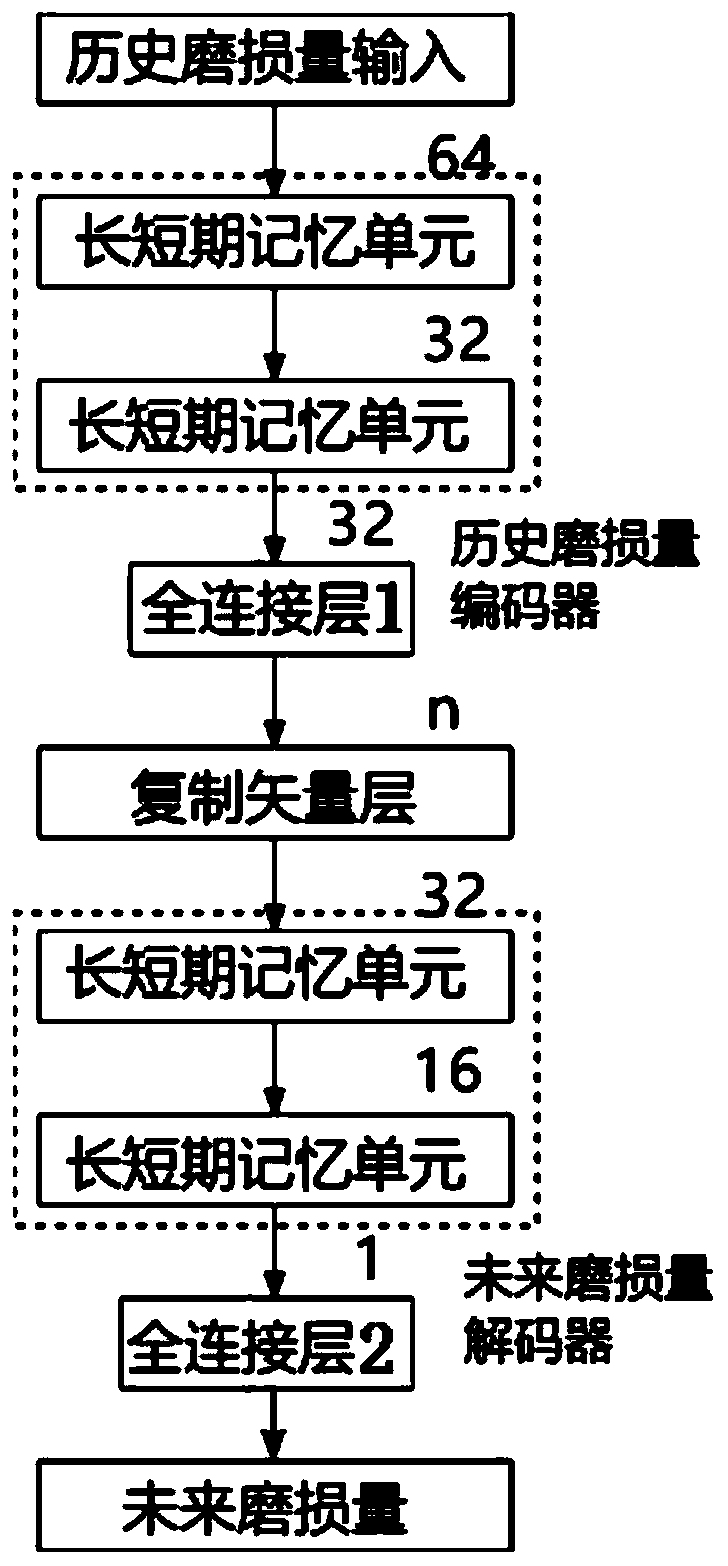

[0033] Such as figure 1 As shown, an online prediction method for future tool wear provided by the present invention includes the following steps:

[0034] Step 1: Take the tool wear from the 1st moment to the mth moment in the machining process as the input sample to form a two-dimensional tensor M with a structure of [m,1] 1 , Take the tool wear at the time m+1 to m+n as the output sample to form a two-dimensional tensor N with the structure [n,1] 1 , Two-dimensional tensor M 1 And the two-dimensional tensor N 1 A sample pair is formed, where m is the number of historical moments of the user-defined tool wear, and n is the number of future moments of the user-defined tool wear; then the tool wear from the second time to the m+1 time As an input sample, form a two-dimensional tensor M with the structure [m,1] 2 , Take the tool wear from m+2 to m+n+1 as the output sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com