Method for preparing superhigh-purity germanium polycrystal

An ultra-high-purity, device-preparing technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, etc., can solve problems such as the inability to effectively improve the purity of germanium polycrystalline, and achieve the effect of stable purity and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

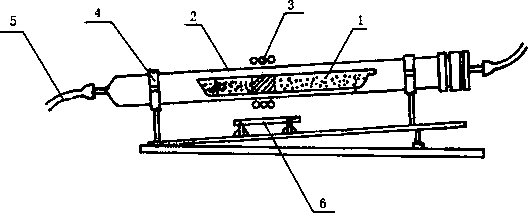

[0028] Embodiment 1: A method for preparing an ultra-high purity germanium polycrystal, which is applied to a germanium polycrystal preparation device, the preparation device includes a quartz boat 1, a quartz tube 2, a zone fusion coil 3, a support 4, an air intake pipe 5, an exhaust gas The tube 6 and the zone melting trolley 7, the quartz boat 1 is placed in the quartz tube 2, the zone melting coil 3 is arranged on the support 4, the quartz tube 2 is fixed on the support 4 and is located between the zone melting coils 3, the intake pipe 5 and the row The gas pipes 6 are respectively arranged at both ends of the quartz tube 2, the zone melting trolley 7 is arranged under the quartz tube 2, the inner surface of the quartz boat 1 is coated with a silicon fume coating, and the zone melting coil 3 is wound by a copper tube with a diameter of 12 mm. A coil with three inner circles and two outer circles is formed, and the width of the zone fusion coil 3 is 3cm; the specific prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com