Adjustable steel wire rope truss device for reinforcing column formwork

A column formwork and steel wire rope technology, applied in the field of adjustable steel wire rope truss devices, can solve the problems of difficulty in meeting relevant requirements for concrete column forming quality, low value of recycling and reuse, waste of material and labor, etc., so as to reduce labor and materials and be easy to disassemble Easy and fast installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

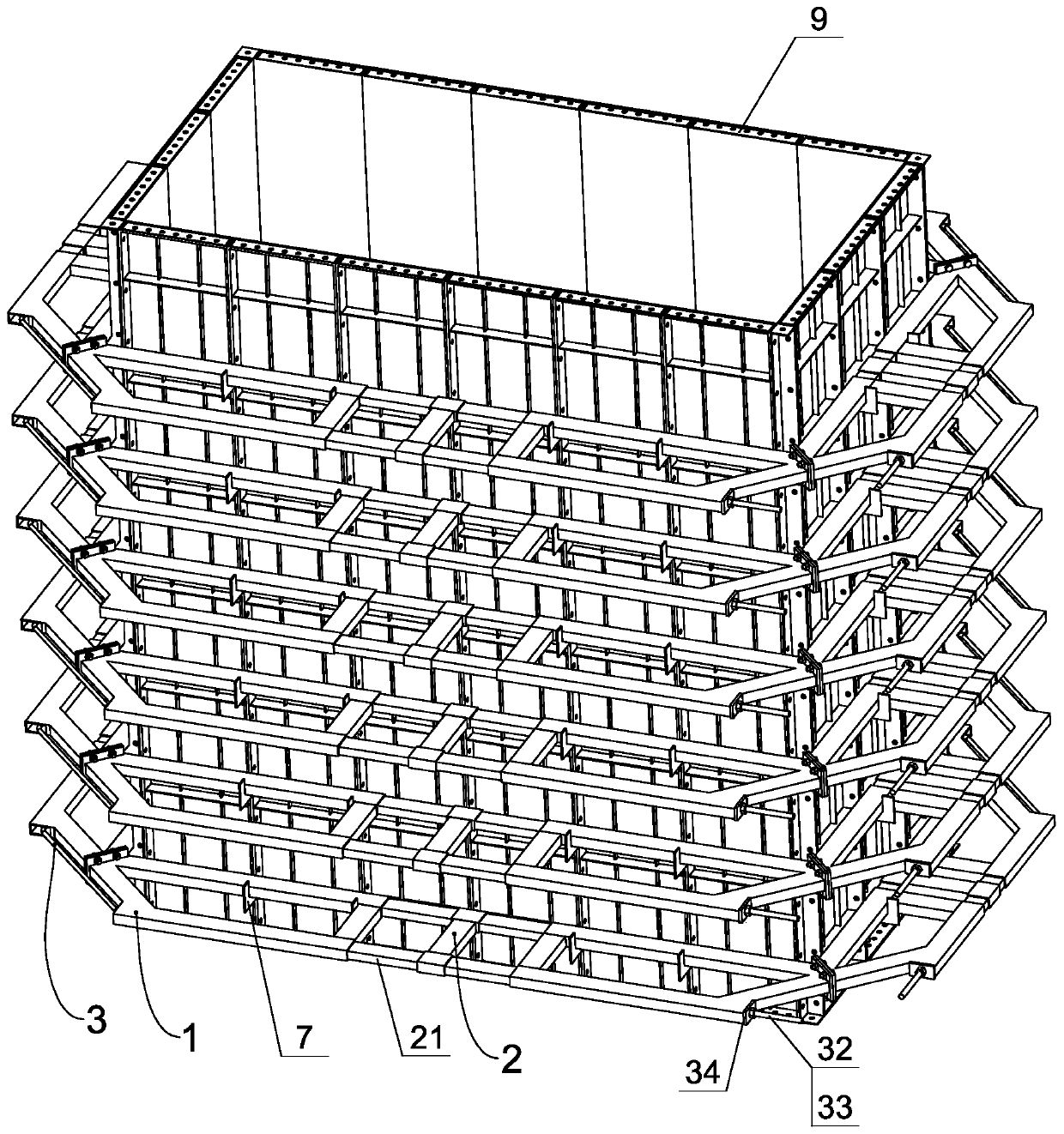

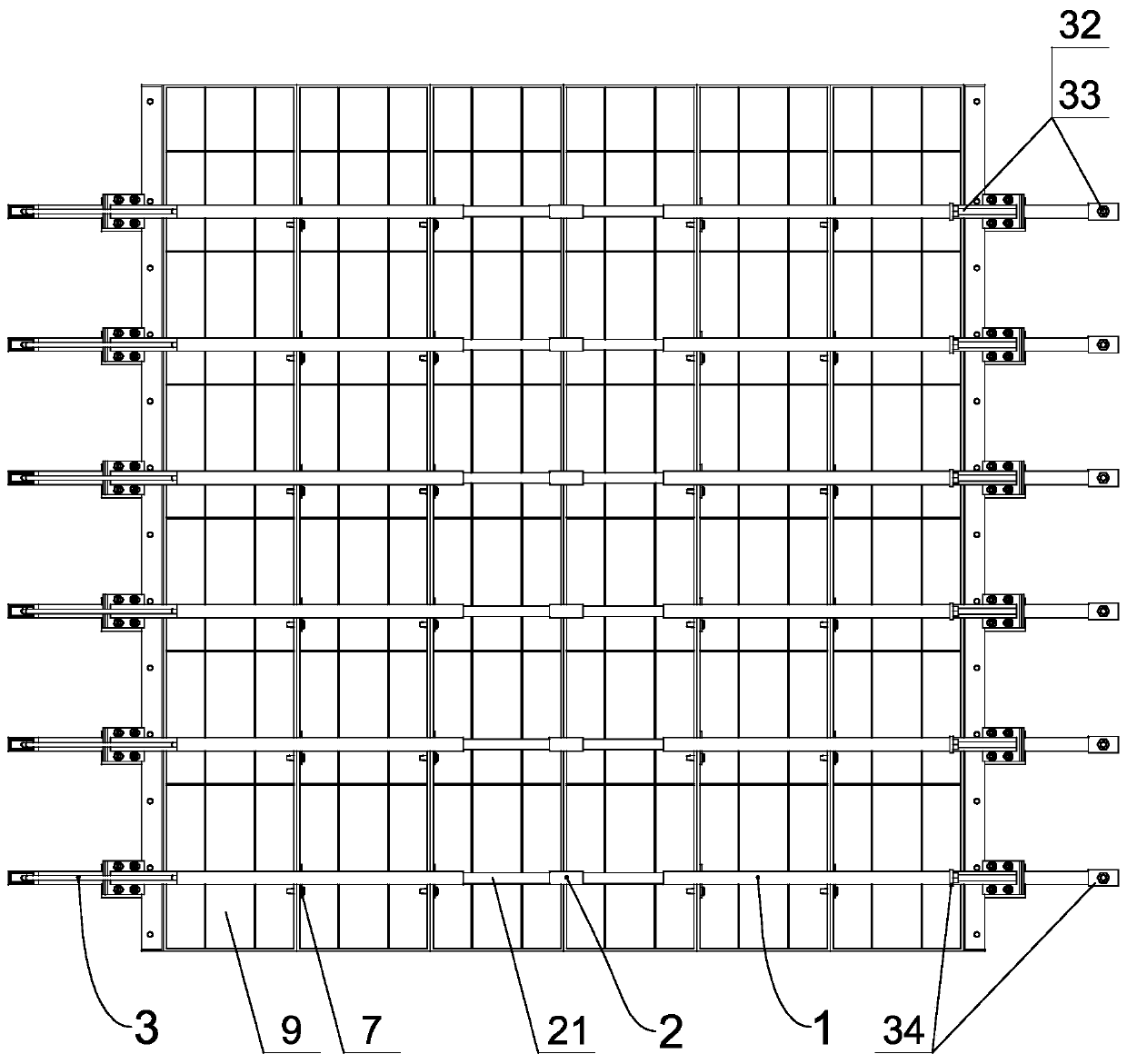

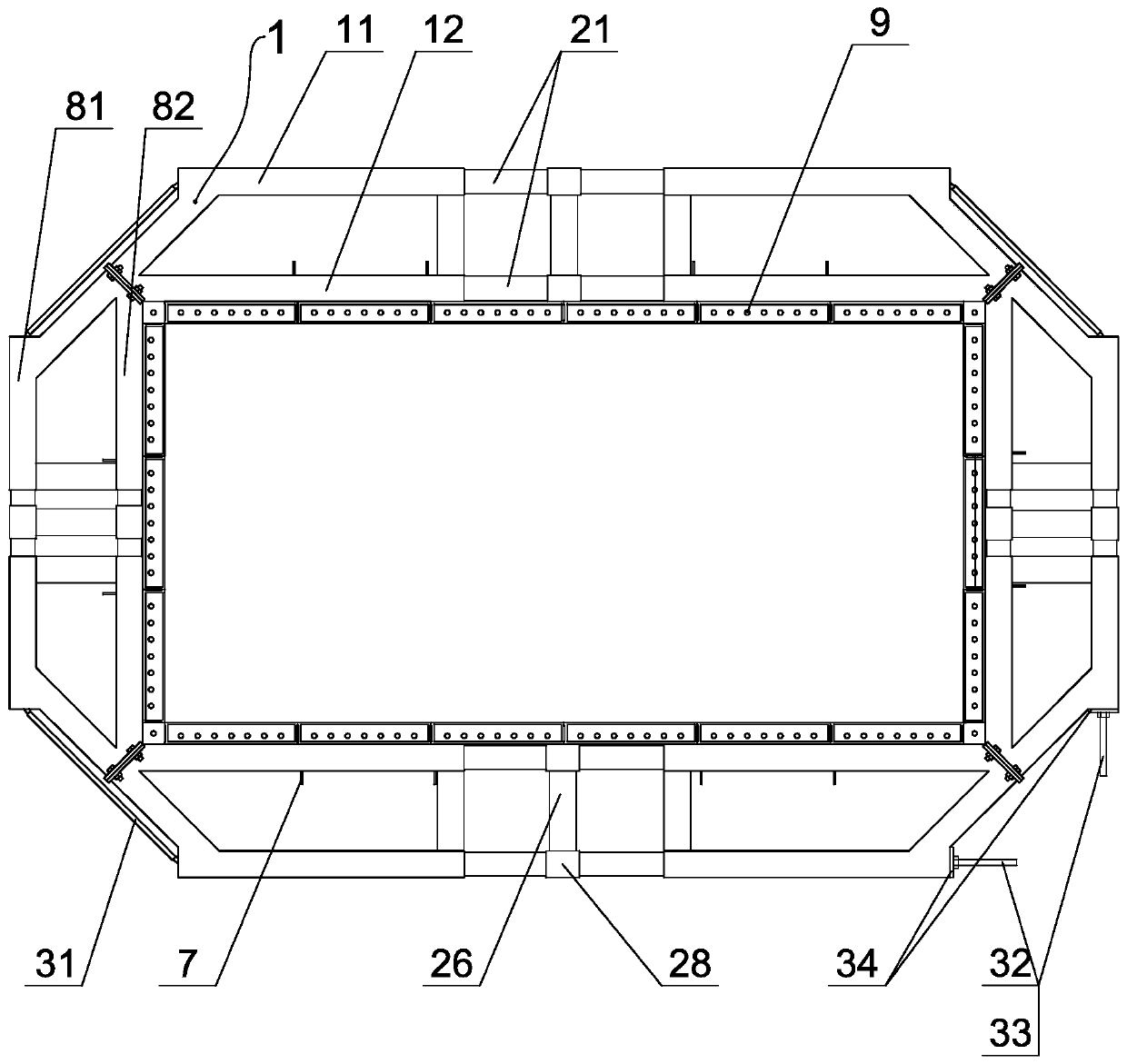

[0027] Such as Figure 1 to Figure 12 As shown, the adjustable steel wire rope truss device used for column formwork reinforcement in this embodiment includes corner back corrugations 1 for the four corners of the column formwork 9, and is used for connecting the adjacent four sides of the column formwork 9. The telescopic back flute 2 connected to the corner back flute 1, and the flexible fastening connector 3 for connecting and fastening the corner back flute 1 and the telescopic back flute 2 in the circumferential direction to form an integrated ring truss. The insertion depth of the telescopic back flute 2 into the corner back flute 1 can be adjusted by plugging between the telescopic back flute 2 and the corner back flute 1, so as to adapt to the reinforcement of column templates of different lengths and widths.

[0028]The corner back flute 1 comprises two parallel first outer flutes 11 and first inner flutes 12, and two parallel second outer flutes 81 and second inner f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com