Integrated multi-row high-pressure radial multi-plunger type variable pump

A multi-plunger, one-piece technology, applied in the field of hydraulic pumps, can solve problems such as increased leakage, increased joint sealing area, increased quality and volume, etc., to achieve reduced leakage, reduced unnecessary volume, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

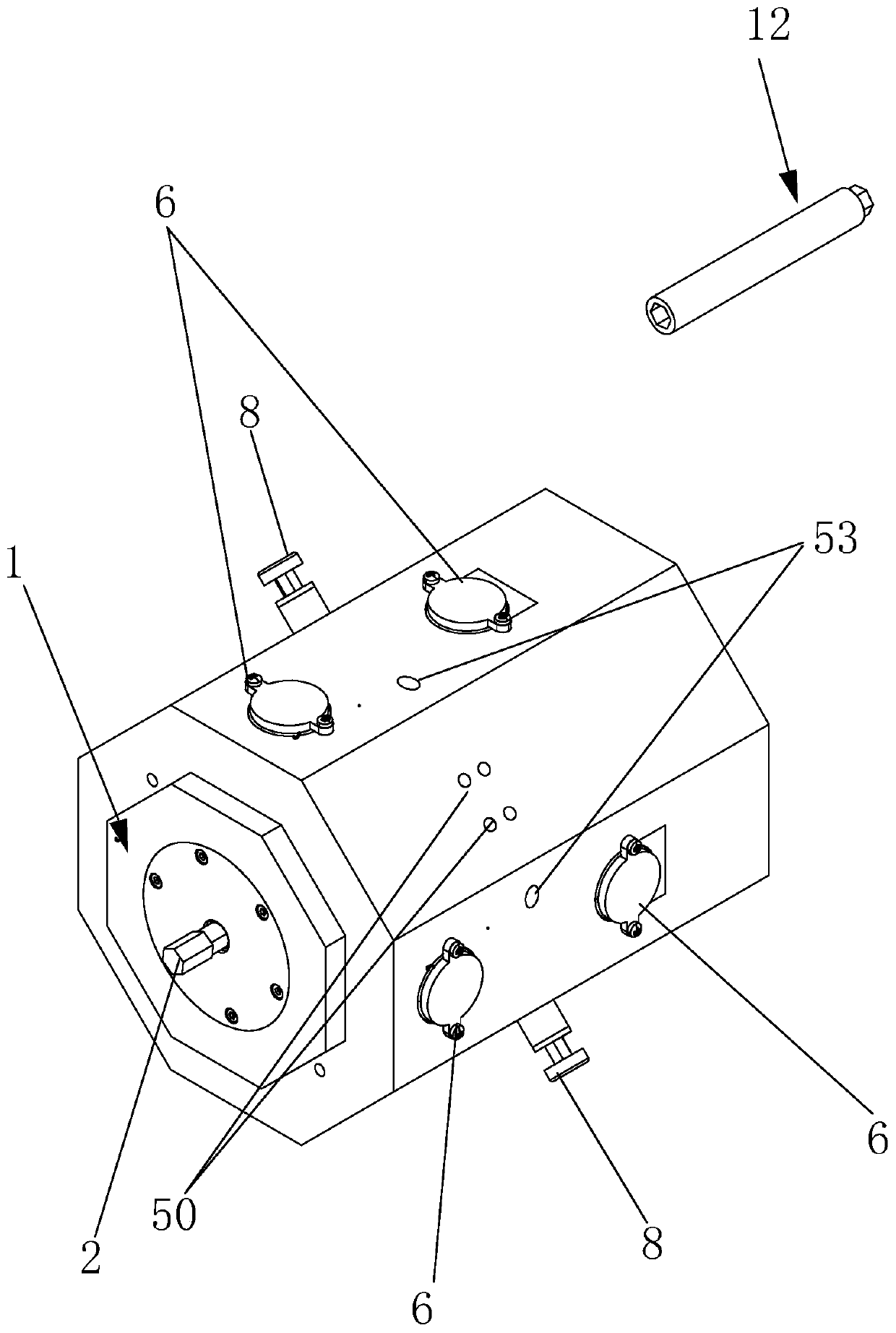

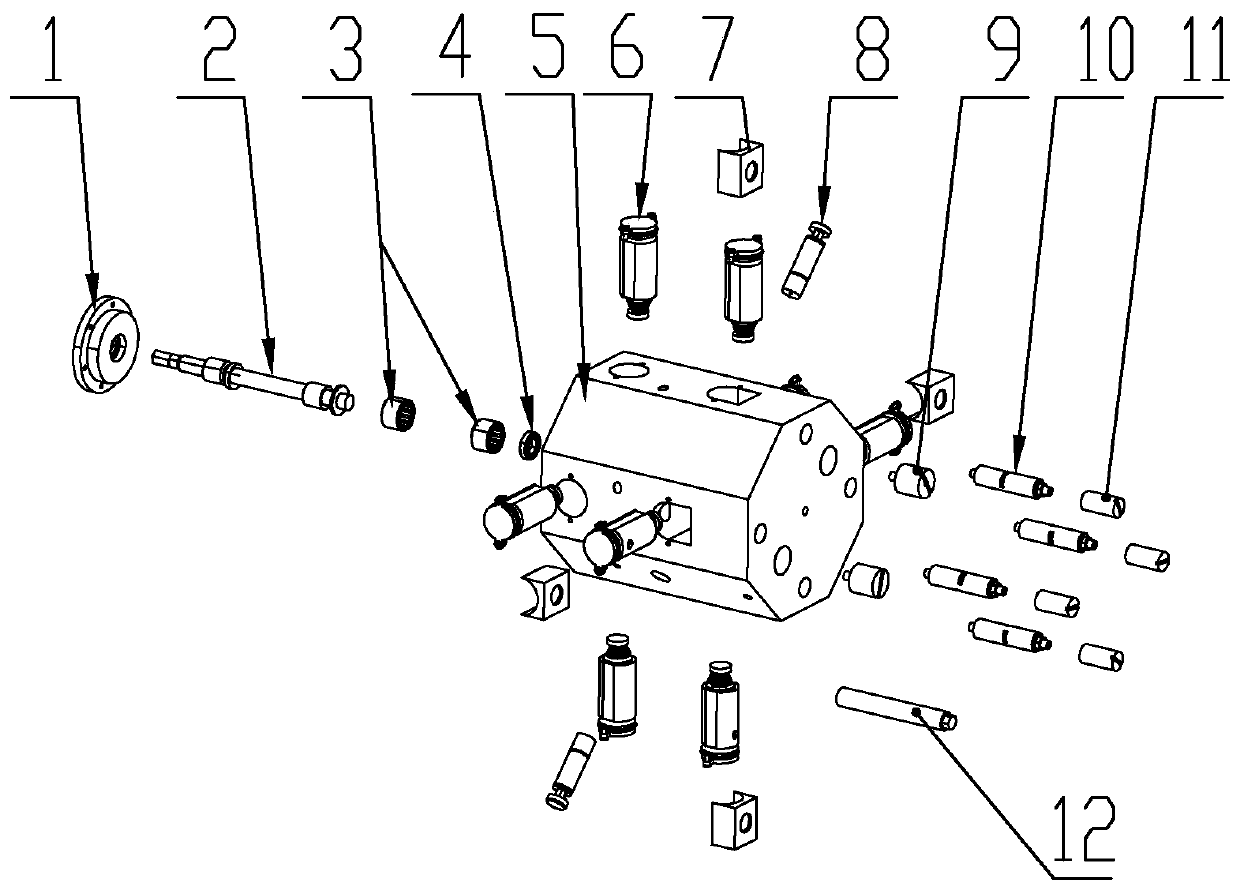

[0032] like figure 1 as well as figure 2 As shown, this embodiment provides an integrated multi-row high-pressure radial multi-piston variable pump, including:

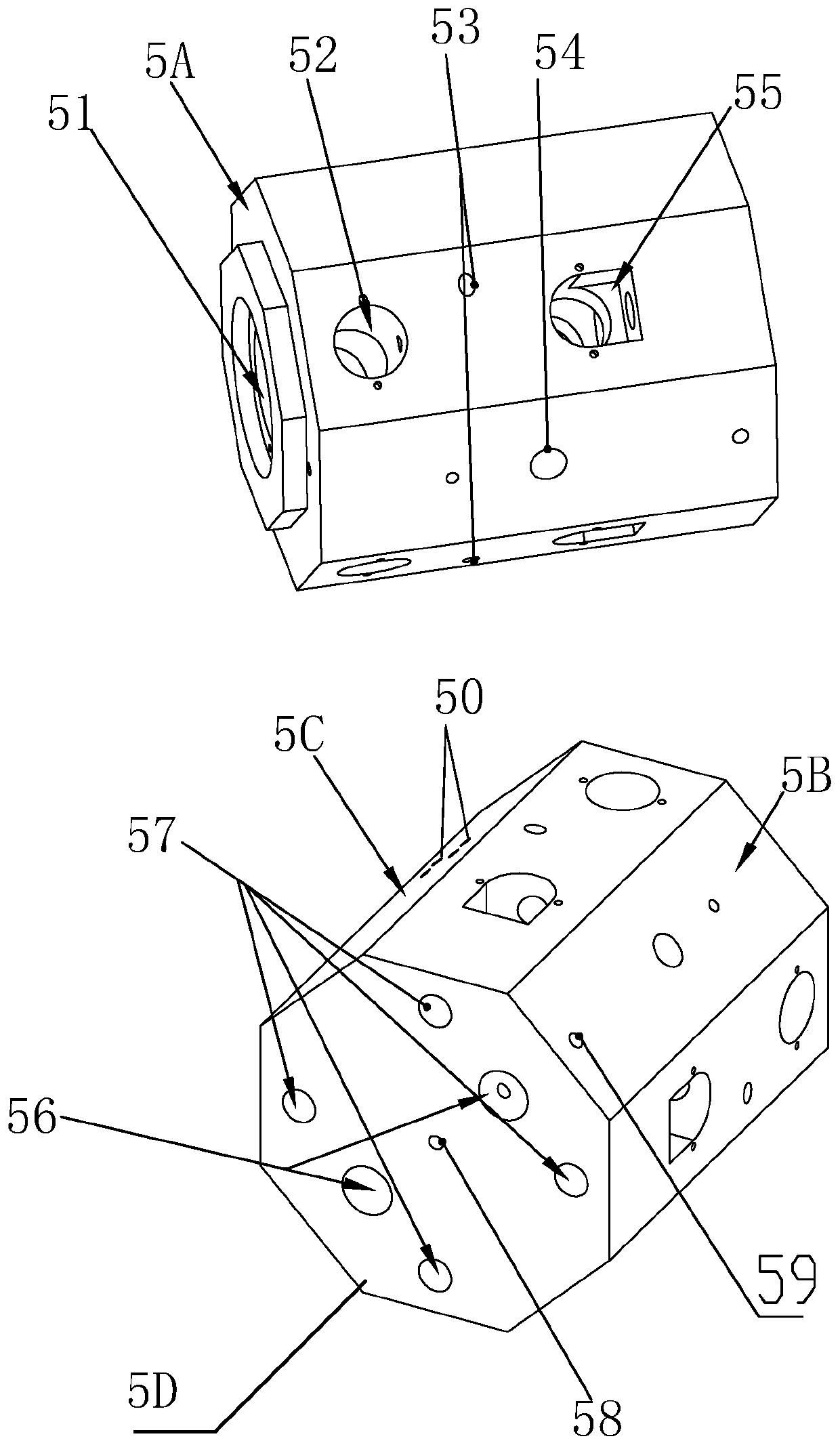

[0033] The pump body 5 is in the shape of an octagonal prism, with two rows of plunger holes for placing the plunger assembly 6 and a second through hole 53 on the four sides, and the rear row of plunger holes has a place for placing fasteners 71, the plunger holes on different sides communicate through the cavity inside the pump body 5, and the first communication channel 571 is provided in the pump body 5 between the plunger holes on the same side, and the rear row of plunger holes 55 The hole wall is provided with a third through hole 57, the third through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com