Denitrification culture device and method for measuring denitrification rate

A culture device and denitrification technology, applied in the field of denitrification measurement, can solve the problems of complex construction process, difficulty in ensuring the airtightness of the system, etc., and achieve the effects of high sensitivity, avoiding obstruction of gas diffusion, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment will provide a denitrification cultivation device.

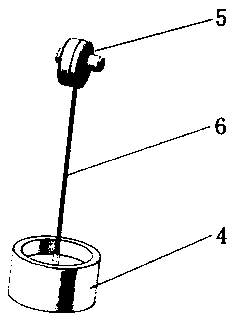

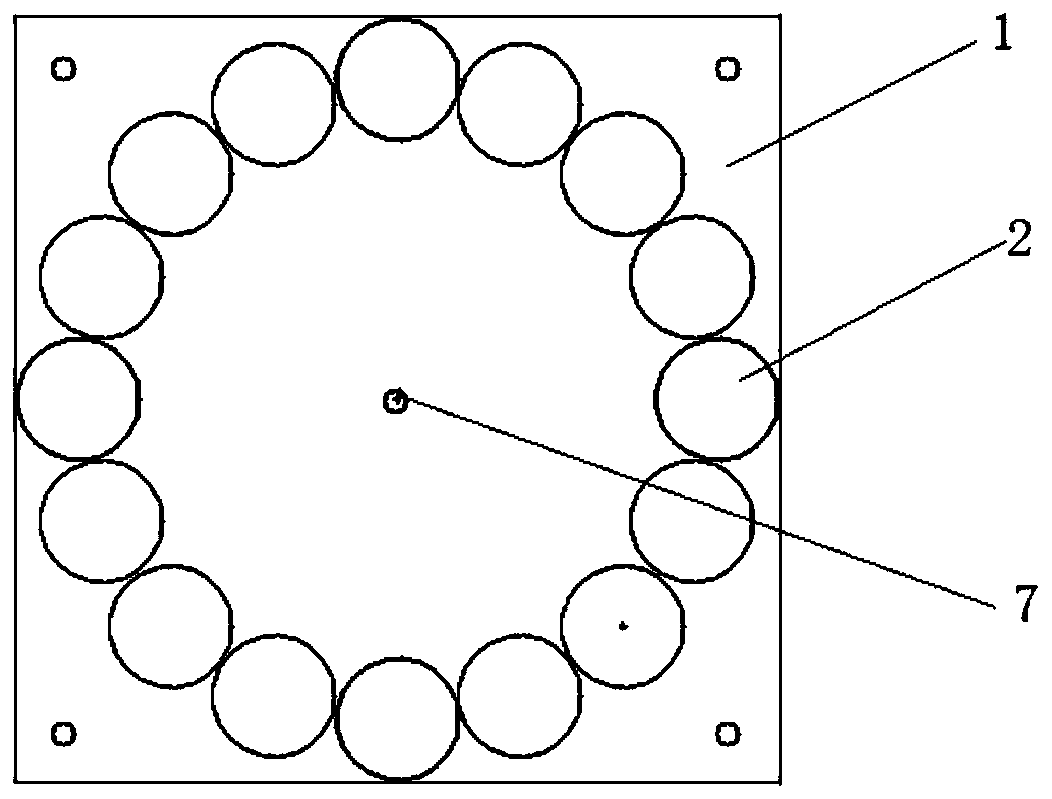

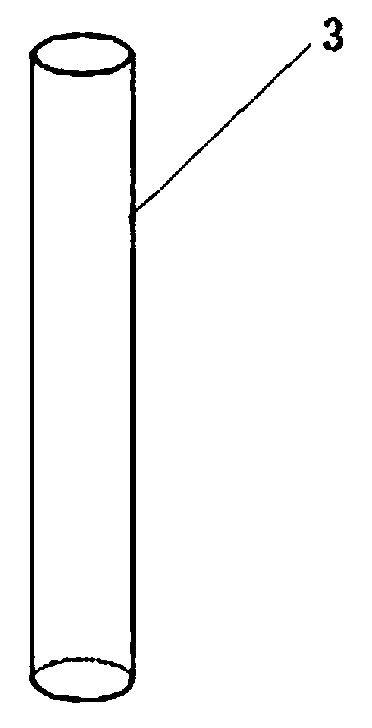

[0043] see Figure 1~3 , shows the denitrification culture device of this embodiment, including a base 1, several straight pipes 3 and a rotating unit. The base 1 is provided with a fixed groove 2 around the center of the base, and the fixed groove 2 is used to place the straight pipe 3 . In this embodiment, the diameter of the straight pipe is 4.7 cm, and the length of the pipe is 29 cm; the number of fixing slots is 16. During use, the fixing slots can be filled or not filled with straight tubes. The bottom opening of the straight pipe 3 is provided with a detachable rubber plug, and the top opening of the straight pipe 3 is provided with a detachable cover 4 with a magnet 5 . Specifically, the magnet 5 is fixedly connected to the inner surface of the cover 4 through a metal wire 6 . The rotating unit includes a rotor, a rotating shaft, and a motor, the rotor is installed in the center of the base,...

Embodiment 2

[0047] This embodiment will provide a kind of denitrification cultivation method utilizing the device of embodiment 1, and the specific steps are as follows:

[0048] In the first step, the soil column is sampled.

[0049]Remove the rubber plug at the bottom of the straight pipe, insert the bottom end of the straight pipe into the original soil column, the soil column is about 6cm deep into the straight pipe, take out the straight pipe and plug the bottom end of the straight pipe with a rubber stopper. In this embodiment, a total of 3 sampling points are collected, 5 soil columns are collected at each sampling point, and 6 soil columns are collected at the last sampling point. After collecting the 16 straight pipes of the soil column, insert them into the fixing grooves on the base in turn, and mark the numbers. Fill the straight pipe with raw water from the top of the straight pipe, cover it, and bring it back to the laboratory for further denitrification cultivation.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com