An ore sorting method and system under an X-ray image based on a convolutional neural network

A convolutional neural network and light image technology, applied in the field of ore sorting methods and systems under X-ray images, can solve the problems of ore having no fixed shape and outline and similar permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

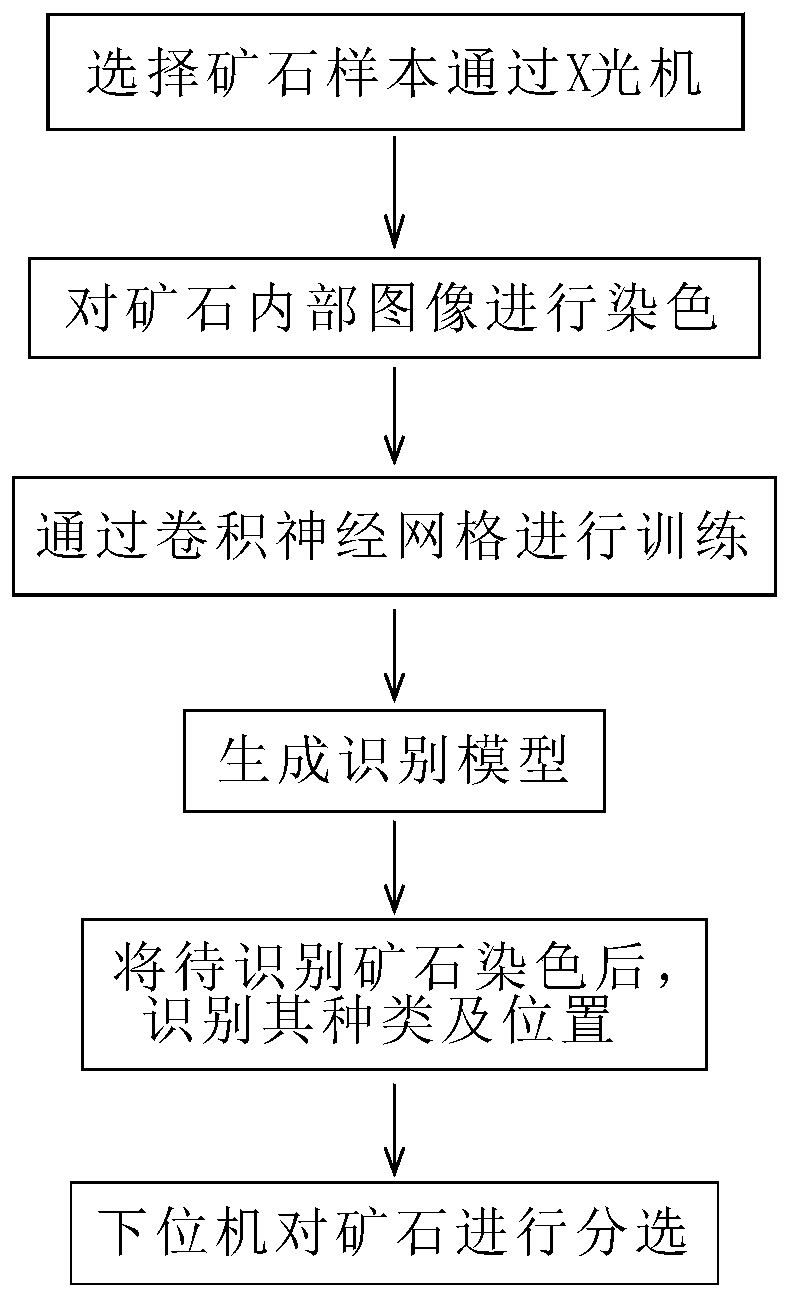

[0022] As shown in the figure, the present invention discloses a method for sorting ore under X-ray images based on convolutional neural network, which is characterized in that it includes the following steps: a. Artificially select a group of different types of ore as samples through X-ray In the process of artificially selecting ore samples, it is necessary to determine the evaluation grade according to the different ore contents inside, and it is also necessary to take into account that although the ore content is high, the ore distribution is scattered and there are many impurities inside. It is possible to train raw ores with different purity and types of ores inside, and accurately identify the model to make the ide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com