Intelligent plate feeding, drilling, sorting and packaging system

A packaging system and sorting system technology, which is applied in the field of plate intelligent feeding, drilling, sorting and packaging systems, can solve the problems of low packaging rate, numerous process steps, waste of packaging materials, etc., achieve high intelligence, reduce costs, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

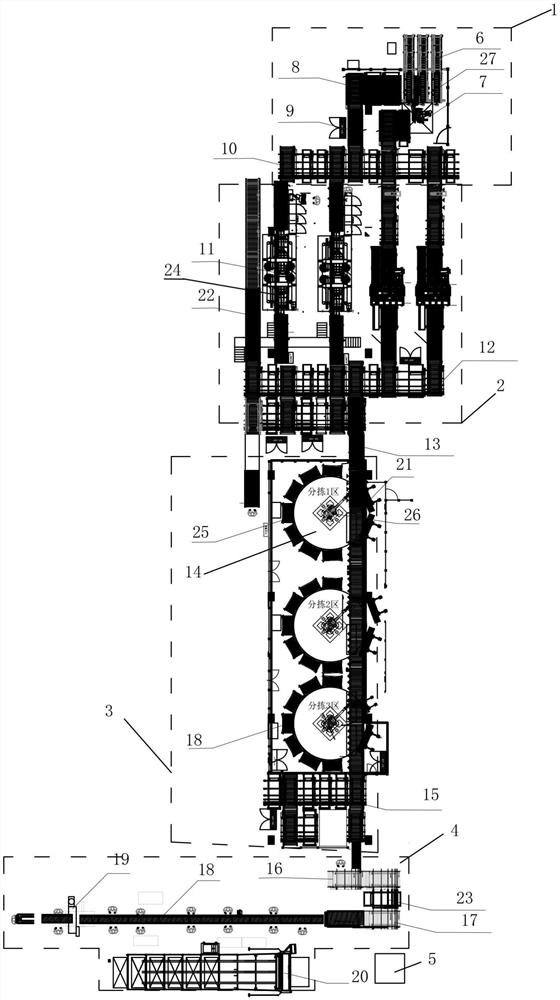

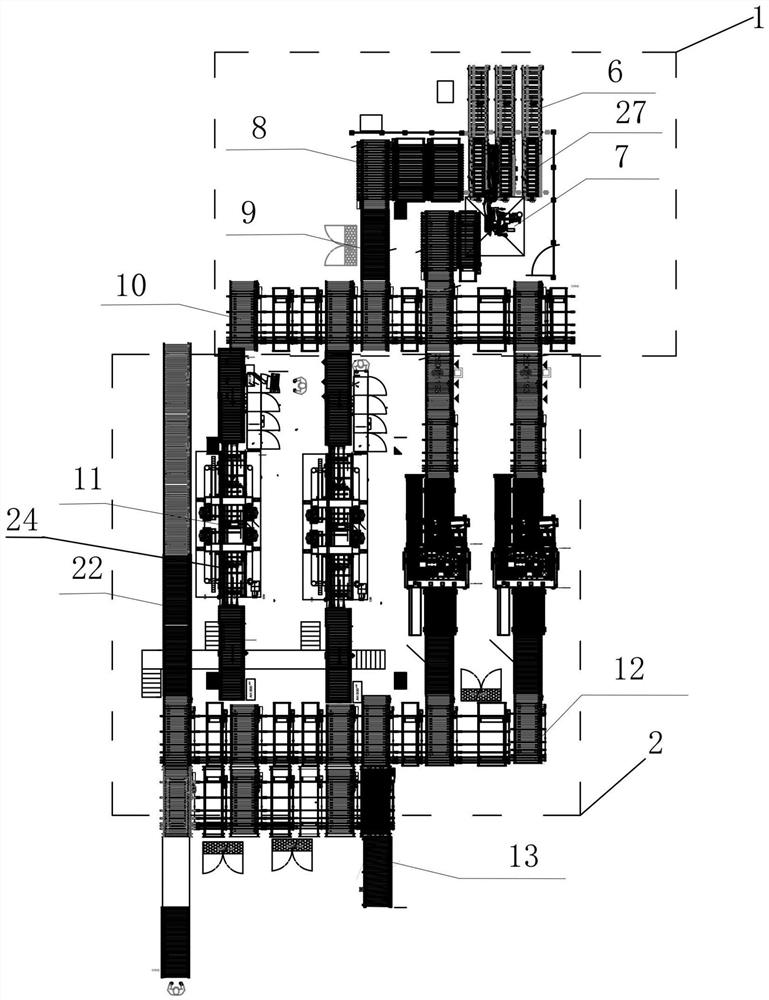

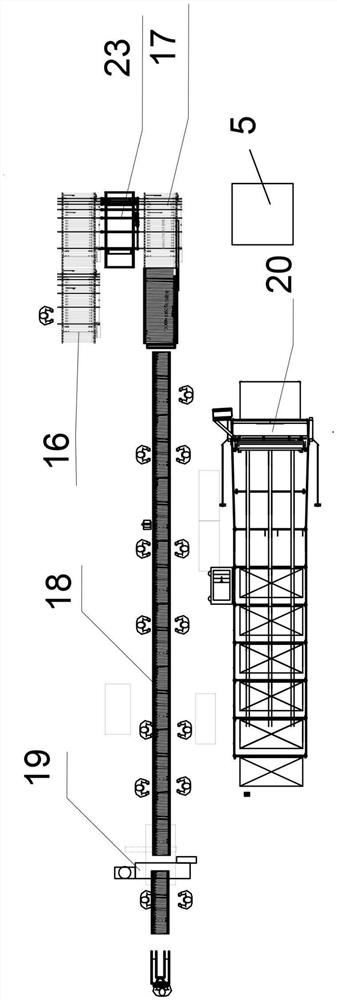

[0024] Such as Figure 1-Figure 4 As shown, a kind of plate intelligent feeding, drilling, sorting and packaging system disclosed in this embodiment includes the following systems connected in sequence:

[0025] Automatic feeding system 1 capable of automatic feeding;

[0026] Drilling connection system 2 capable of automatic hole turning;

[0027] Intelligent sorting system capable of automatic sorting3;

[0028] Packaging off-line system 4 capable of automatic packaging and off-line transmission;

[0029] Wherein, the packaging off-line system 4, the intelligent sorting system 3, the drilling connection system 2, and the automatic feeding system 1 are all electrically connected to the controller 5, and the automatic feeding system 1 includes more than one set of The automatic feeding drum line 6, a feeding manipulator 7 and the feeding conveying line 8 are provided with a plate elevator 27 on the automatic feeding drum line 6, and the material feeding manipulator 7 convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com