Sintering method of cylindrical sintered NdFeB

A sintering method and NdFeB technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of low qualification rate, large bending deformation of blanks, and easy fracture of blanks, so as to improve the qualification rate , Improve the pass rate and control the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

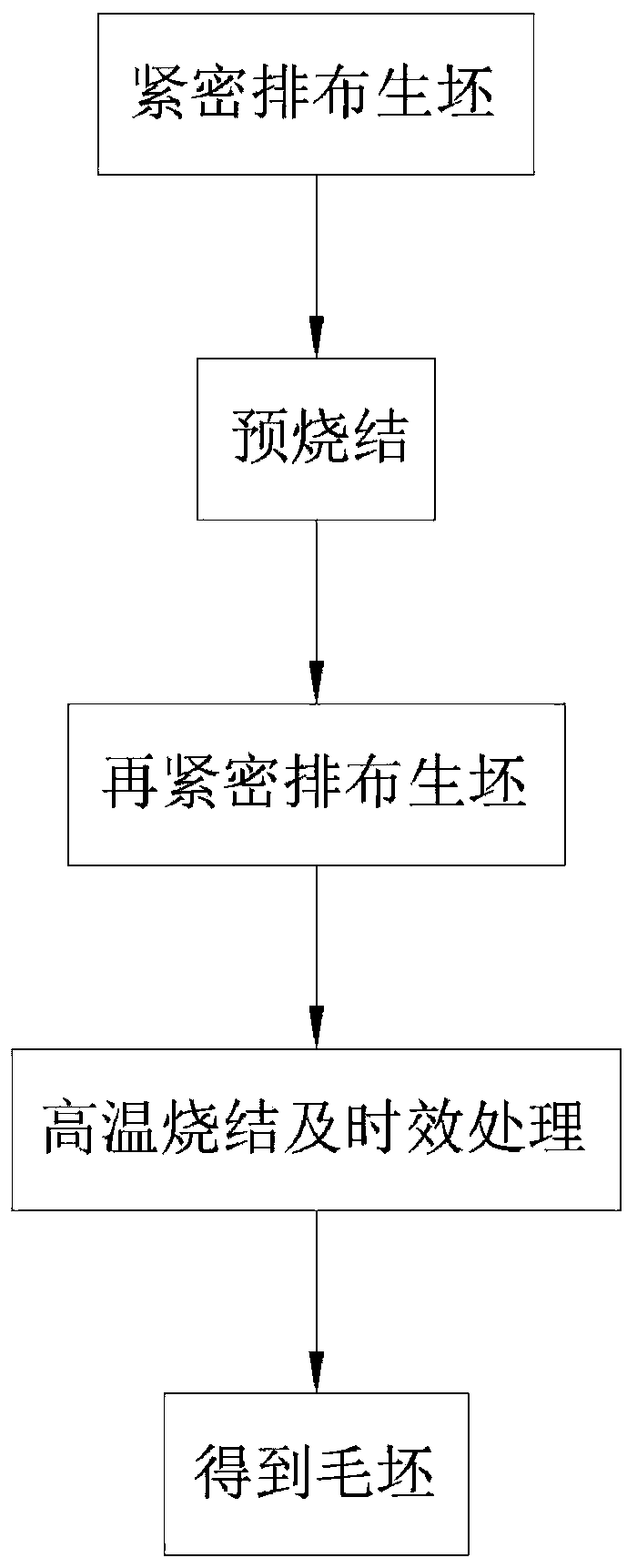

Image

Examples

Embodiment 1

[0033] The performance is N35, and the NdFeB cylinder with a blank size of 4mm in diameter and 35mm in length is sintered. First, in a protective gas environment, closely arrange the NdFeB cylindrical green bodies, so that the adjacent NdFeB cylindrical green bodies stick together; then, in a vacuum state, pre-sinter the closely arranged NdFeB cylindrical green bodies , the pre-sintering temperature is 990 ℃, the pre-sintering time is 2 h; then, cool out of the furnace, and then tightly arrange the NdFeB cylindrical green bodies, so that the adjacent NdFeB cylindrical green bodies stick together; finally, carry out high-temperature sintering and two times of sintering on the rearranged NdFeB cylindrical green bodies Fire treatment, high temperature sintering temperature is 1045 ℃, the sintering time is 4.5 h; primary tempering temperature is 870 ℃, the primary tempering time is 2 h; the secondary tempering temperature is 520 ℃, the secondary tempering time is 4.5 h.

...

Embodiment 2

[0038] The performance is N35, and the NdFeB cylinder with a blank size of 4mm in diameter and 40mm in length is sintered. First, in a protective gas environment, closely arrange the NdFeB cylindrical green bodies, so that the adjacent NdFeB cylindrical green bodies stick together; then, in a vacuum state, pre-sinter the closely arranged NdFeB cylindrical green bodies , the pre-sintering temperature is 1000 ℃, the pre-sintering time is 2 h; then, cool out of the furnace, and then tightly arrange the NdFeB cylindrical green bodies, so that the adjacent NdFeB cylindrical green bodies stick together; finally, carry out high-temperature sintering and two times of sintering on the rearranged NdFeB cylindrical green bodies Fire treatment, high temperature sintering temperature is 1045 ℃, the sintering time is 4.5 h; primary tempering temperature is 870 ℃, the primary tempering time is 2.5 h; the secondary tempering temperature is 520 ℃, the secondary tempering time is 4.5 h. ...

Embodiment 3

[0043] The performance is N38, and the NdFeB cylinder with a blank size of 4mm in diameter and 45mm in length is sintered. First, in a protective gas environment, closely arrange the NdFeB cylindrical green bodies, so that the adjacent NdFeB cylindrical green bodies stick together; then, in a vacuum state, pre-sinter the closely arranged NdFeB cylindrical green bodies , the pre-sintering temperature is 1000 ℃, the pre-sintering time is 2h; then, cool out of the furnace, and then tightly arrange the NdFeB cylindrical green bodies, so that the adjacent NdFeB cylindrical green bodies stick together; finally, carry out high-temperature sintering and two times of sintering on the rearranged NdFeB cylindrical green bodies Fire treatment, high temperature sintering temperature is 1050 ℃, the sintering time is 4.5 h; primary tempering temperature is 870 ℃, the primary tempering time is 2.5 h; the secondary tempering temperature is 500 ℃, the secondary tempering time is 5 h.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com