Intelligent heat-moisture driven core spun yarn and moisture-absorbing and quick-drying fabric

A moisture-absorbing, quick-drying and bag-driving technology, applied in yarn, knitting, warp knitting, etc., can solve the problems of difficulty in ensuring the uniformity of fabrics and low moisture absorption of fabrics, and achieve the effect of improving air permeability and increasing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

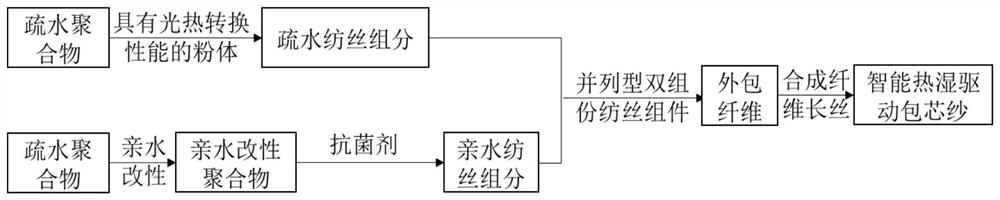

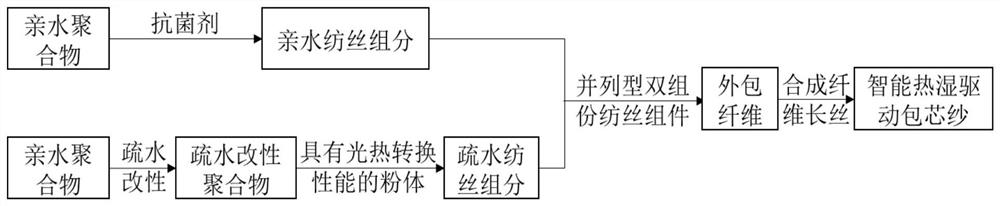

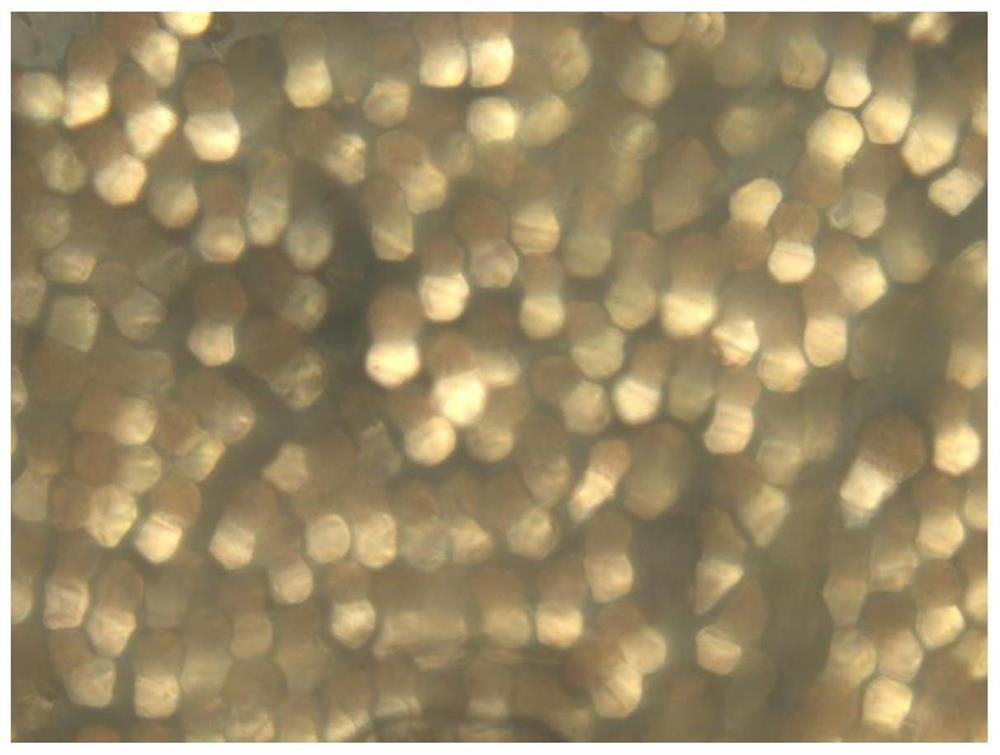

[0034] An intelligent heat-moisture-driven core-spun yarn, including core yarn and outer fiber, the core yarn is polyester filament with a fineness of 48dtex; the outer fiber is composed of hydrophilic antibacterial fiber and hydrophobic light-to-heat conversion fiber The cross-section is a peanut-shaped side-by-side composite fiber with a fineness of 28 dtex, and the mass ratio of the polyester filament to the outer fiber is 30:70. The hydrophobic light-to-heat conversion fiber is composed of polyethylene terephthalate and far-infrared ceramic powder, and the hydrophilic antibacterial fiber is composed of terephthalic acid, ethylene glycol, polyethylene glycol and 1,2 - Composition of copolymer of butanediol and nano-silver. The outer covering fiber is prepared by the following method:

[0035] S1. Preparation of spinning components: melt-blending the copolymer of nano-silver and terephthalic acid, ethylene glycol, polyethylene glycol and 1,2-butanediol in a twin-screw extru...

Embodiment 2~5

[0043] Compared with Example 1, the smart thermal-moisture-driven core-spun yarns provided in Examples 2 to 5 are different in that the diameter ratio of the hydrophilic antibacterial fiber and the hydrophobic light-to-heat conversion fiber in the outer covering fiber, and the ratio of the diameter of the polyester filament and the outer covering fiber. The quality ratio of the fibers is shown in Table 1, and the others are basically the same as in Example 1, and will not be repeated here.

[0044] The intelligent heat-moisture-driven core-spun yarn provided in Examples 2-5 was knitted into a moisture-absorbing and quick-drying fabric, and the test results of its moisture-absorbing and quick-drying performance are shown in Table 1.

[0045] Preparation conditions and moisture absorption and quick-drying performance test results of Table 1 Examples 2 to 5

[0046] Example diameter ratio mass ratio Water absorption / % Evaporation rate g / h Moisture permeability ...

Embodiment 6~11

[0050] Compared with Example 1, the intelligent heat-moisture driven core-spun yarn provided in Examples 6-11 differs in that the fineness of the core yarn, the outer covering fiber and the core-spun yarn are as shown in Table 2, and the others are the same as in Example 1. They are basically the same and will not be repeated here.

[0051] The preparation conditions of table 2 embodiment 6~11

[0052]

[0053]

[0054] The intelligent heat-moisture-driven core-spun yarn provided in Examples 6-11 was knitted into a moisture-absorbing and quick-drying fabric, and the test results of its moisture-absorbing and quick-drying performance are shown in Table 3.

[0055] Table 3 The moisture absorption and quick-drying performance test results of the moisture-absorbing and quick-drying fabrics provided by Examples 6-11

[0056] Example Water absorption / % Evaporation rate g / h Moisture permeability g / (m 2 h)

[0057] It can be seen from Table 3 that the greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com