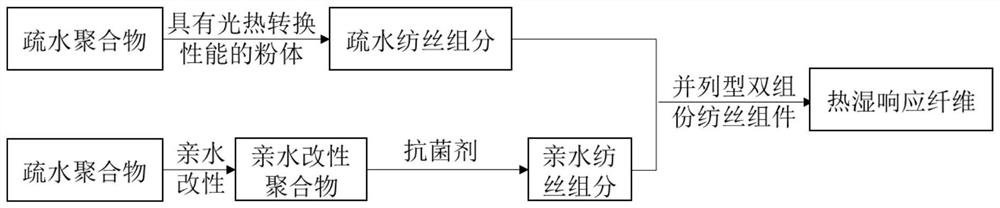

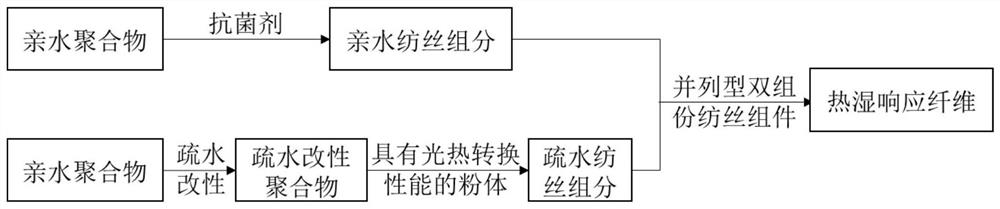

Heat and moisture responsive fiber with light-to-heat conversion and antibacterial properties and preparation method thereof

A light-to-heat conversion and performance technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve problems such as discrimination, improve adhesion, reduce spinning difficulty, and make it easier to form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

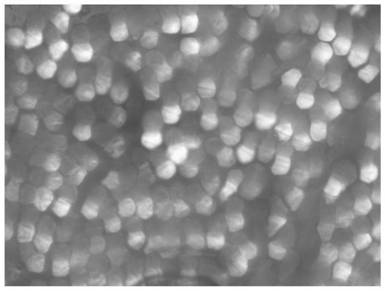

[0036] A heat-humidity responsive fiber with light-to-heat conversion and antibacterial properties, which is obtained by spinning a hydrophilic spinning component and a hydrophobic spinning component through a side-by-side spinning component, and the hydrophobic spinning component is made of polyethylene terephthalate Composed of ethylene glycol formate and far-infrared ceramic powder, the hydrophilic spinning component is composed of a copolymer of terephthalic acid, ethylene glycol, polyethylene glycol and 1,2-butanediol and nano silver, Its preparation method comprises the following steps:

[0037] S1. Preparation of spinning components: melt-blending the copolymer of nano-silver and terephthalic acid, ethylene glycol, polyethylene glycol and 1,2-butanediol in a twin-screw extruder to obtain the Hydrophilic spinning component, melt-blending far-infrared ceramic powder and polyethylene terephthalate in a twin-screw extruder to obtain the hydrophobic spinning component;

[0...

Embodiment 2~8

[0047] Compared with Example 1, the heat and moisture responsive fibers provided in Examples 2 to 6 with light-to-heat conversion and antibacterial properties are different in that the diameter of the heat and moisture responsive fibers and the hydrophilic spinning components and hydrophobic spinning components The diameter ratio of the points is shown in Table 1, and the others are basically the same as those in Embodiment 1, and will not be repeated here.

[0048] Table 1 The preparation conditions of Examples 2 to 6 and the bending angle test results to light heat and humidity stimulation

[0049]

[0050]

[0051] It can be seen from Table 1 that as the diameter of the fiber increases, the amount of deformation produced by it when it is stimulated by the outside gradually decreases. This is because the larger the diameter of the fiber, the smaller the degree of orientation of the fiber, and the more scattered the distribution of internal molecular chains. , the great...

Embodiment 7~14

[0053] The heat-humidity responsive fibers with light-to-heat conversion and antibacterial properties provided in Examples 7-14 are different from those in Example 1 in that the types and amounts of antibacterial agents and powders with light-to-heat conversion functions are shown in Table 2 As shown, the others are basically the same as those in Embodiment 1, and will not be repeated here.

[0054] Table 2 The preparation conditions of Examples 7-14 and the bending angle test results to light heat and humidity stimulation

[0055]

[0056]

[0057] It can be seen from Table 2 that when the light-to-heat conversion powder such as zirconium carbide or magnesium carbide is selected, the bending deformation of the heat-humidity responsive fiber in response to light-heat and humidity stimuli is not much different, indicating that changing the type of light-to-heat conversion powder Heat and humidity response fiber properties have little effect. With the increase of the amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com