Device and method for increasing capacity of oil-immersed transformer

An oil-immersed transformer and transformer technology, applied in the field of transformers, can solve the problems of heavy construction and renovation work, long construction period, and complexity, and achieve the effects of less difficult construction, shorter construction period, and lower operating temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

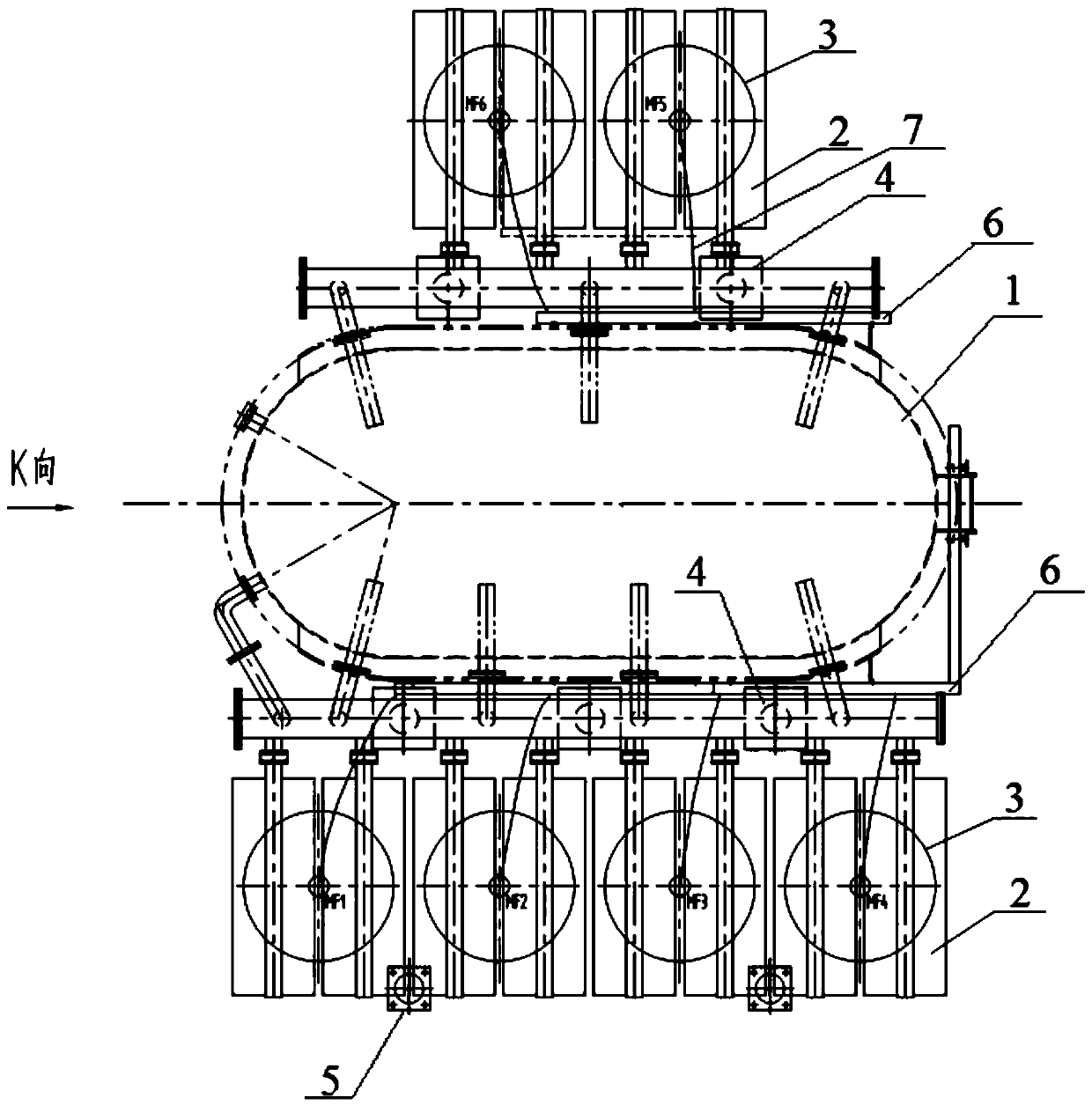

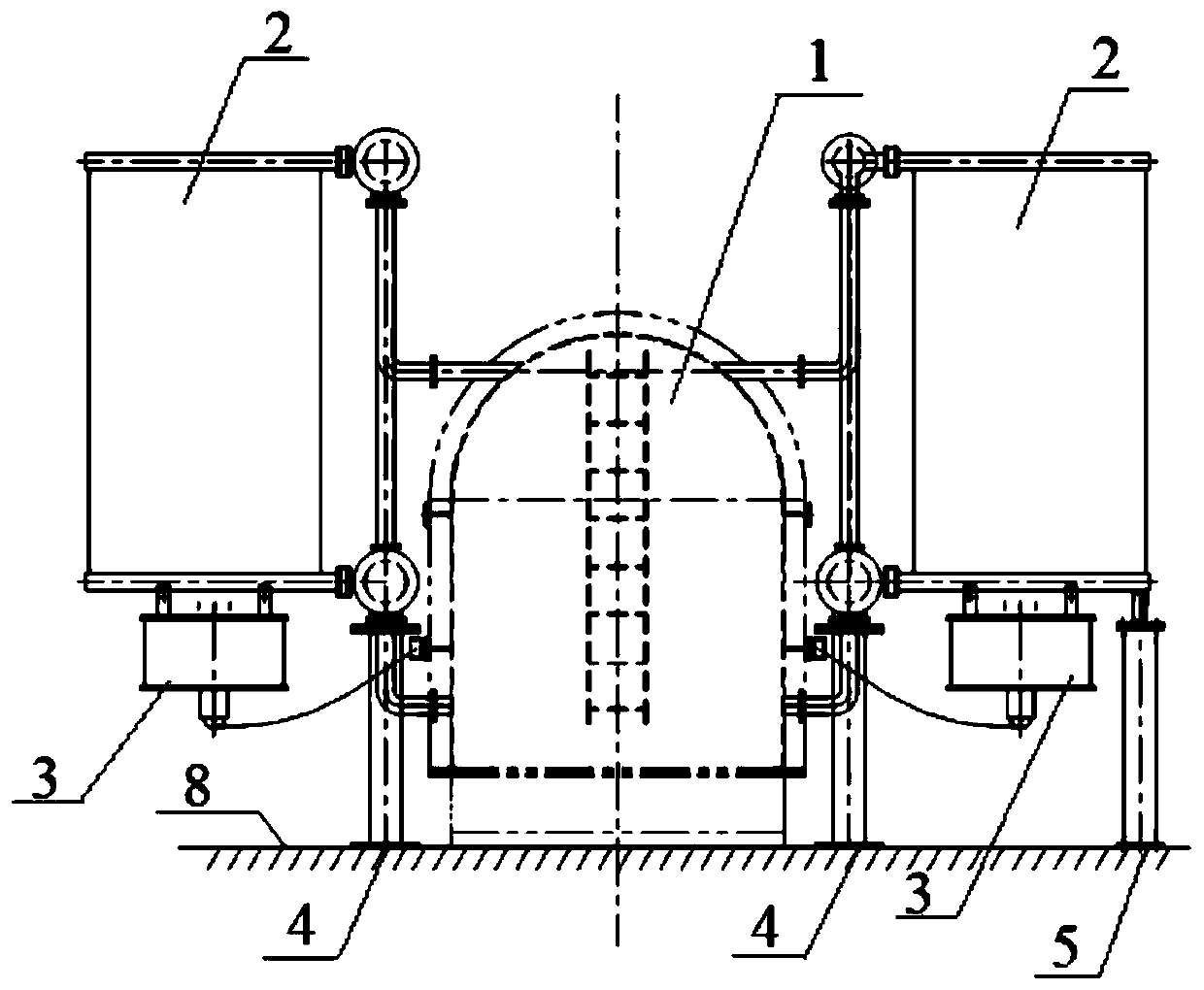

[0033] Example 1, such as figure 1 As shown, a device for increasing the capacity of an oil-immersed transformer according to the embodiment of the present invention includes: a fin radiator 2, a cooling fan 3 and a control box. The chip radiator 2 is installed on the return pipe of the transformer body 1. There are twelve groups of chip radiators 2, among which, eight groups are located on the high voltage side of the transformer body 1, and four groups are located on the low voltage side of the transformer body 1. The cooling fan 3 is installed on the fin radiator 2, and there are six cooling fans 3 in total. Among them, four cooling fans 3 are installed on the fin radiator 2 on the high voltage side of the transformer body 1, and two cooling fans 3 are installed on the transformer body. On the fin radiator 2 on the low-voltage side of the body 1. The control box is located outside the transformer body 1 and connected with the motor of the cooling fan 3 .

[0034] Further,...

Embodiment 2

[0038] Embodiment 2, the present invention also provides a method for increasing the capacity of an oil-immersed transformer, the method comprising the following steps:

[0039] Step 1, install fin radiators 2 on the return pipes on both sides of the oil tank of the transformer body 1. There are twelve groups of fin radiators 2, of which eight groups are located on the high-voltage side of the transformer body 1, and four groups are located on the transformer body 1 low pressure side.

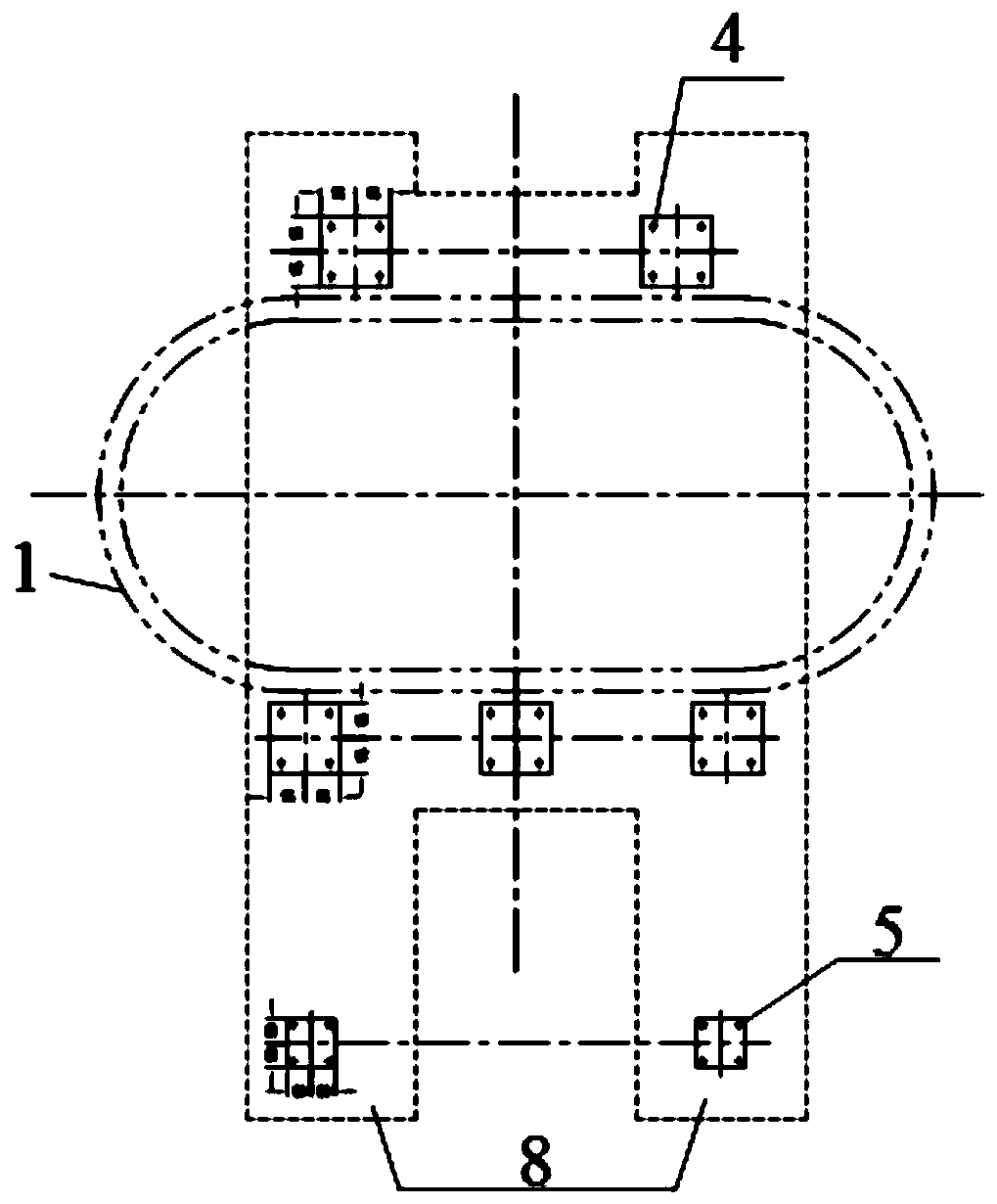

[0040] Step 2, install the return pipes on both sides of the oil tank of the transformer body 1 on the transformer foundation 8 through the bottom plate A4.

[0041] There are five base plates A 4 in total, three of which are located on the high-voltage side of the transformer body 1 and two are located on the low-voltage side of the transformer body 1 . The three bottom plates on the high voltage side of the transformer body 1 are evenly arranged. Each bottom plate A 4 is fixed on the transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com