An internal heating method suitable for power battery packs

A technology for power battery packs and power batteries, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as uneven preheating, and achieve uniform heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

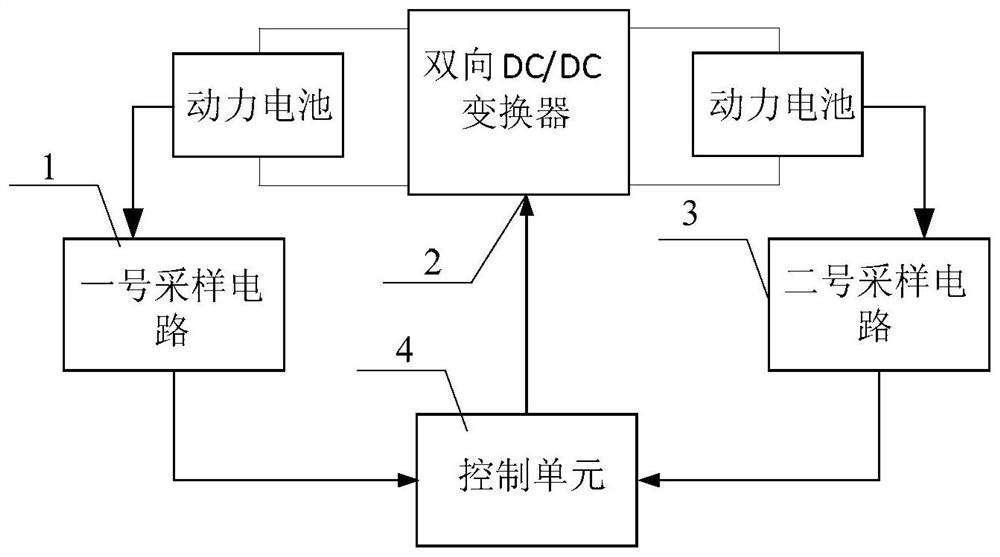

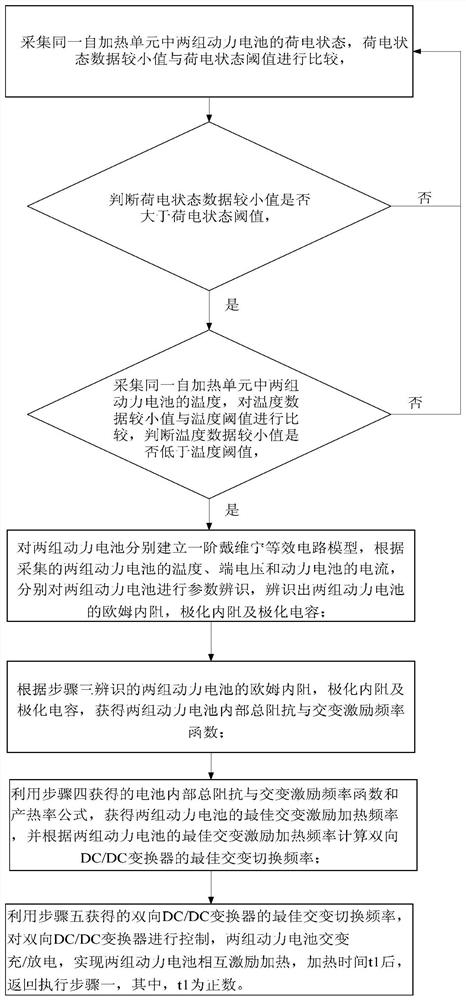

[0019] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, an internal heating method suitable for a power battery pack described in this embodiment, the power battery pack described in this method includes an even number of power batteries inside, and each two groups of power batteries are a self-heating unit, The charging and discharging signal terminals of one group of power batteries of each heating unit are connected to the signal input and output terminals on one side of the bidirectional DC / DC converter 2, and the charging and discharging signal terminals of the other group of power batteries are connected to the other side of the bidirectional DC / DC converter 2. side signal input and output terminals;

[0020] No. 1 sampling circuit 1 and No. 2 sampling circuit 3 are respectively used to collect the temperature, terminal voltage, internal current of the power battery and the state of charge of the power battery ...

specific Embodiment approach 2

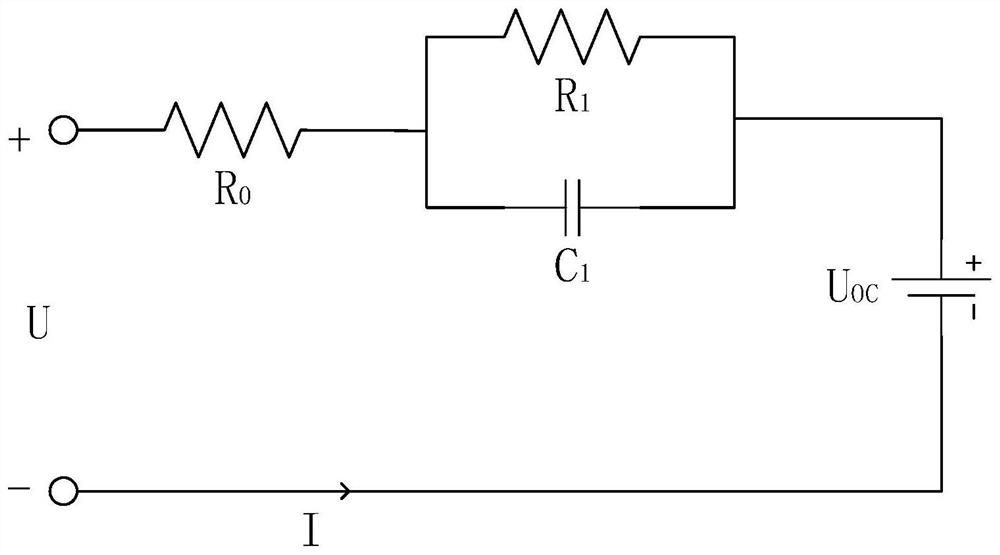

[0028] Specific implementation mode two: the following combination image 3 Describe this embodiment. This embodiment will further explain an internal heating method suitable for power battery packs described in Embodiment 1. The first-order Thevenin equivalent circuit model described in step 3 includes the ohmic internal resistance R 0 , Polarization resistance R 1 , Polarized capacitance C 1 and open circuit equivalent voltage source U OC ;

[0029] Ohm internal resistance R 0 One end of the connection is connected to the positive pole of the charging power supply, and the ohmic internal resistance R 0 The other end of the polarized capacitor C is connected at the same time 1 one end and the polarization resistance R 1 One end of the polarized capacitance C 1 The other end of the polarizing resistor R 1 The other end of the open circuit equivalent voltage source U OC The positive pole of the open circuit equivalent voltage source U OC The negative pole of the batte...

specific Embodiment approach 3

[0030] Specific embodiment three: This embodiment further explains an internal heating method suitable for power battery packs described in embodiment two. The formula of the first-order Thevenin equivalent circuit model described in step three is:

[0031]

[0032] Among them, R 0 is the ohmic internal resistance, R 1 is the polarization internal resistance, C 1 is the polarized capacitance, U OC is the open circuit voltage of the lithium-ion battery, U is the terminal voltage of the lithium-ion battery, and s is the complex frequency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com