HDMI terminal structure and manufacturing method thereof

A technology of HDMI terminal and production method, which is applied in the field of electronic telecommunications, can solve problems such as easy shaking, affecting communication quality, and a large number of mold sets, so as to improve market competitiveness, reduce signal crosstalk, and ensure injection molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

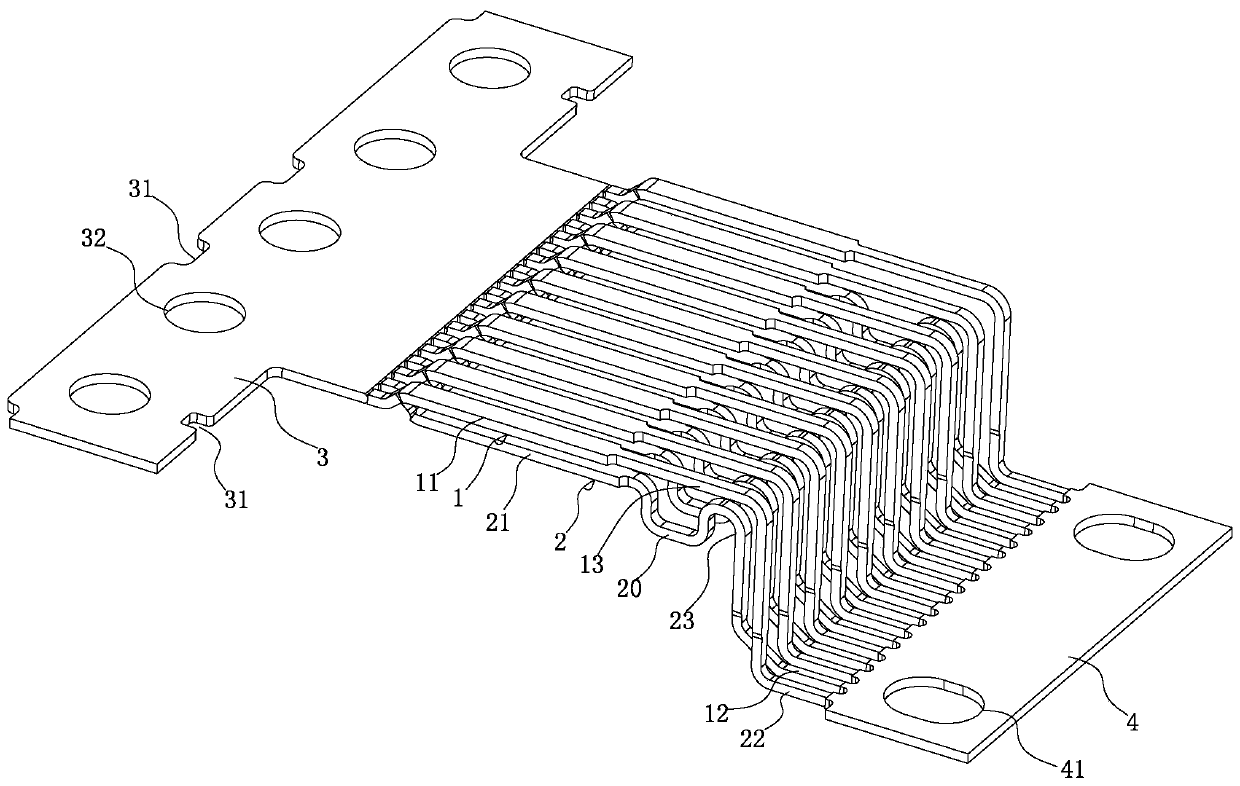

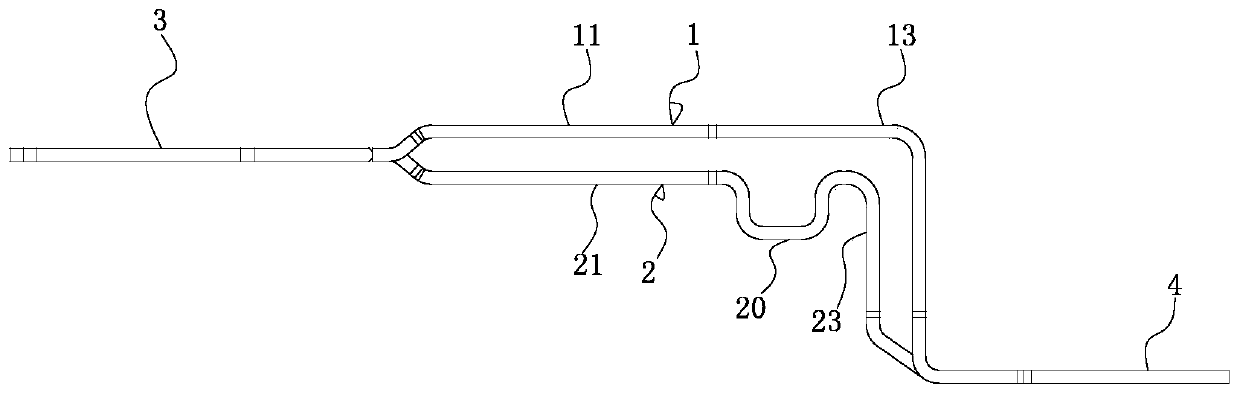

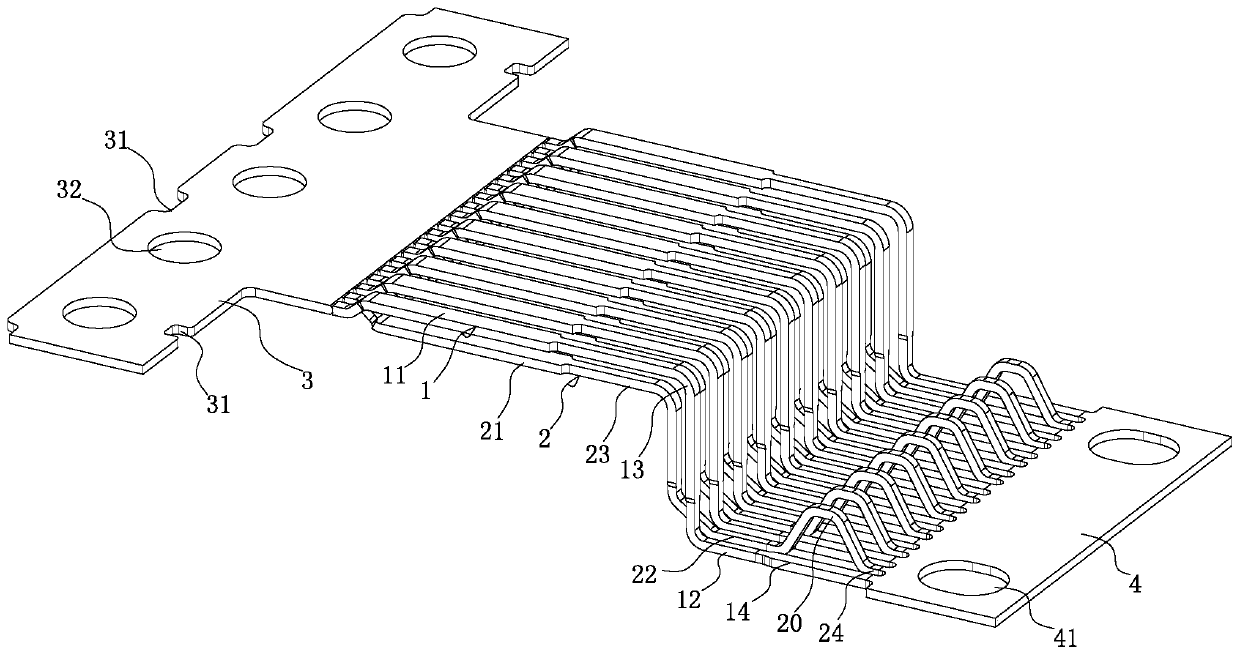

[0027] See Figure 1-4As shown, it is an HDMI terminal structure. The HDMI terminal structure includes a first terminal 1 and a second terminal 2 formed by cutting in half and tearing up and down and distributed in two layers of staggered upper and lower layers, wherein the first terminal 1 It includes a first contact portion 11 that is solidly integrated and sequentially connected, a bent first main body portion 13 and a first solder leg 12; the second terminal 2 includes a second contact portion 21 that is solidly integrated and sequentially connected , the bent second main body portion 23 and the second solder leg 22; the end portion of the first contact portion 11 of the first terminal 1 and the end portion of the second contact portion 21 of the second terminal 2 are uniformly connected to the first The side of the tape 3, and the first conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com