Device for reducing pore diameter of elbow

A pipe bend and hole diameter technology, which is applied in transportation and packaging, forming tools, safety equipment, etc., can solve the problems of slow shrinkage of the bend pipe, no shrinkage, and cracking of the bend pipe mouth, so as to avoid extrusion cracking and compression resistance Strong ability and the effect of improving the success rate of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It will be described in detail below in conjunction with specific embodiments according to the accompanying drawings.

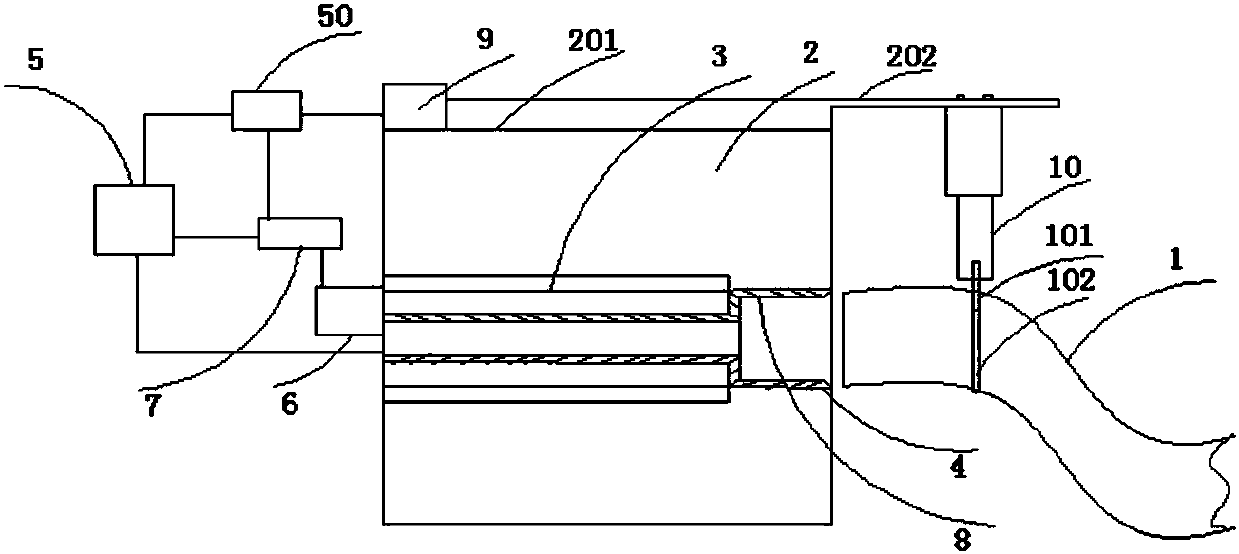

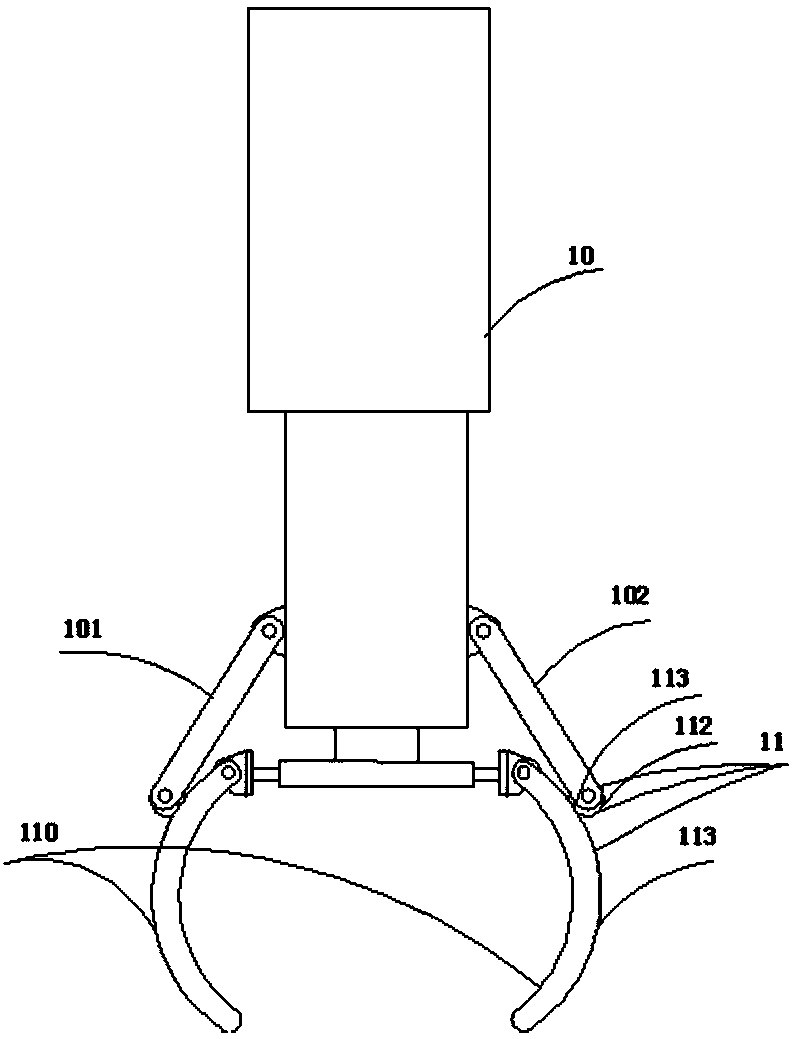

[0025] like figure 1 , 2 The shown device for reducing the aperture of an elbow includes a driving device (50), an elbow 1, and a fixing seat 2. A heating element 8 is arranged inside the fixing seat 2, and the outside of the heating element 8 is wrapped with a heat-insulating and pressure-resistant component 4. The driving device is connected with an automatic heating device and an automatic extruding device 9, and the automatic extruding device 9 is arranged around the heat-insulating and pressure-resistant component 4;

[0026] The automatic heating device comprises a heater 5, a high temperature detector 6, a relay 7 and a heating element 8 connected by wires to form a closed-loop structure;

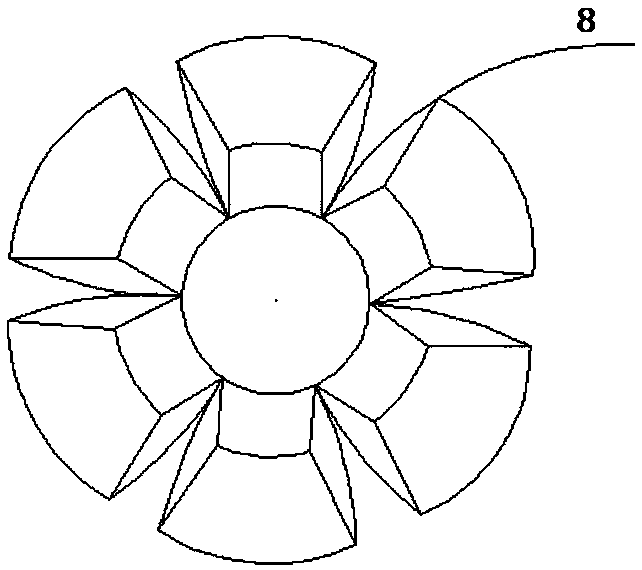

[0027] The fixing seat 2 is provided with a through hole, and there are 6 or more heating elements 8 with a fan-shaped cross-section that can move toward t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com