Immersion type water hole heating rotating device and working method thereof

A heating, rotating, immersion technology, applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problem of not being able to actively control the temperature and flow mode of the mold, and achieve light weight, accurate temperature, and equipment body. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

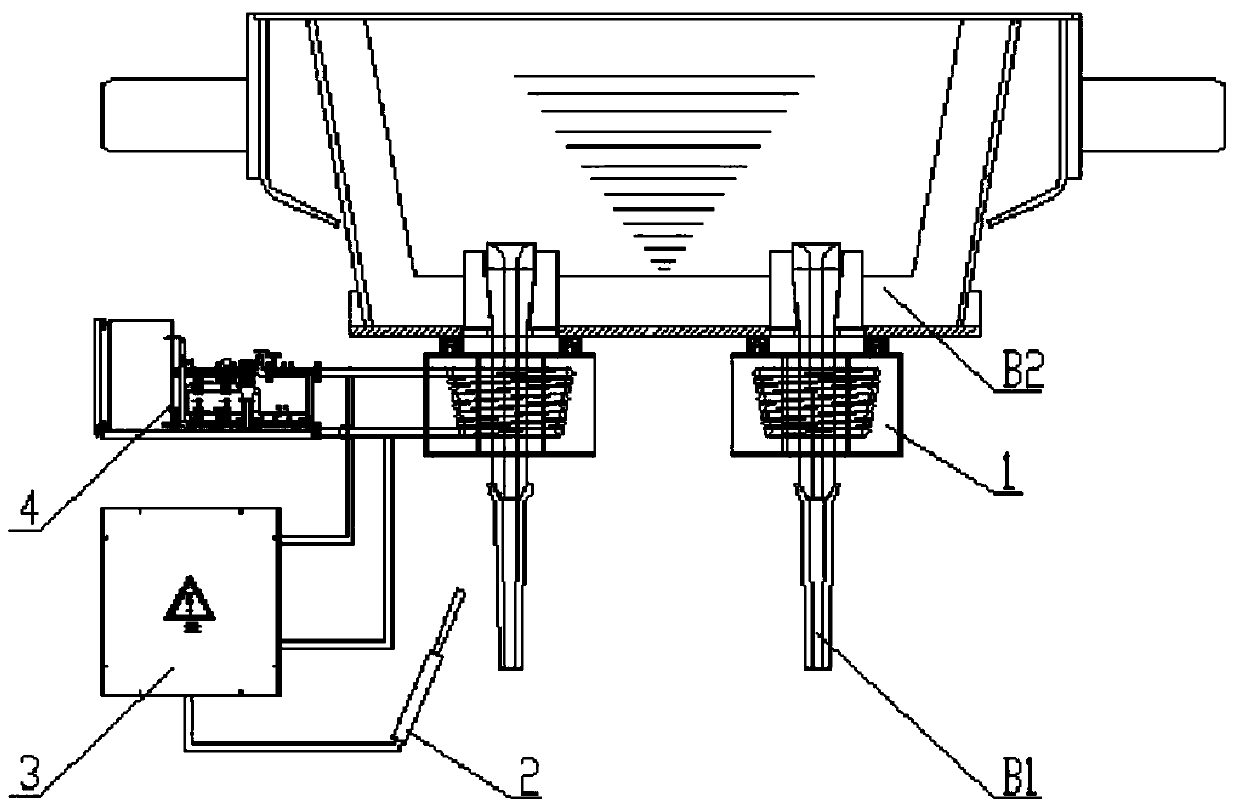

[0041] Make two sets such as figure 1The shown submerged nozzle heating rotating device is respectively installed on the bottom of the tundish B2 of the first and second flow submerged nozzles of the continuous casting machine in the steel plant. The specific installation method is as follows:

[0042] (1) Install the submerged nozzle and adjust the center of the submerged nozzle;

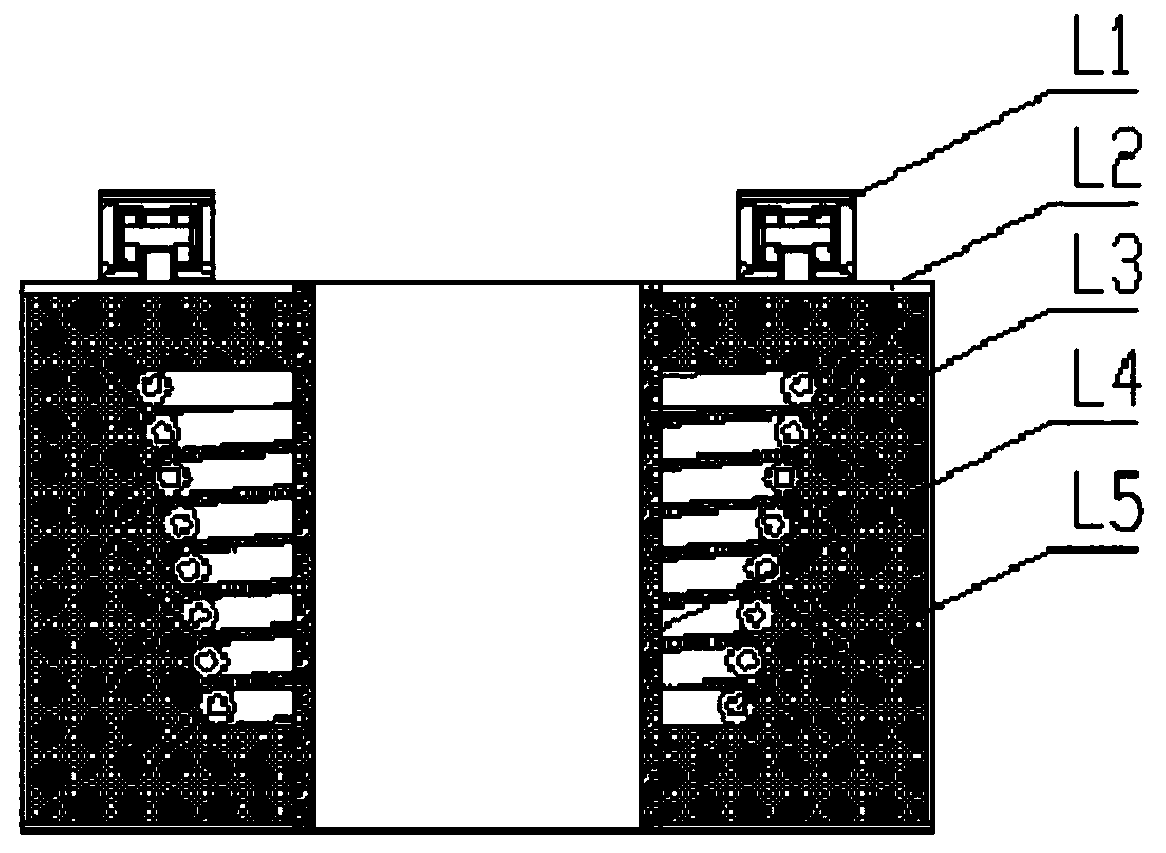

[0043] (2) The sensor passes through the submerged nozzle, and then the sensor body is fixed on the bottom of the tundish with the mounting bracket on it, and the coaxiality error between the center of the sensor body and the center of the submerged nozzle is not greater than 3mm;

[0044] (3) Connect the sensor to the cooling device, connect the sensor to the control system, and connect the temperature measuring device to the signal of the control system.

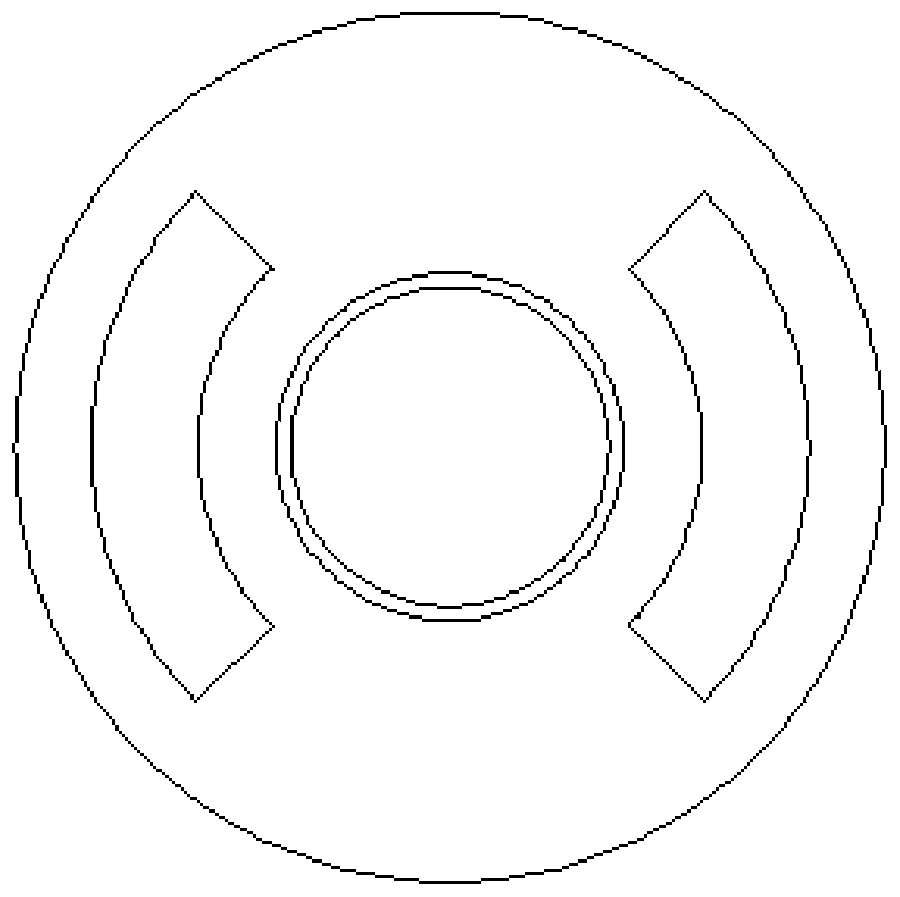

[0045] The submerged nozzle B1 is a split nozzle with an outer diameter of φ80mm and a total length of 1250mm. The electrical parameters of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com