A three-dimensional porous heat-proof structure conformal preparation mold and preparation method

A three-dimensional porous, heat-proof technology, applied in household appliances, other household appliances, household components, etc., can solve problems such as uneven impregnation, avoid insufficient impregnation, achieve rapid circulation, and good operation friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a conformal preparation method of a three-dimensional porous heat-proof structure, comprising the following steps:

[0067] Step 1, preparing a prefabricated body with a three-dimensional porous structure;

[0068] Specifically, it is preferable to use a three-dimensional needle-punching process or a three-dimensional weaving process to prepare a preform with fiber distribution in the plane and in the thickness direction.

[0069] Step 2, placing the prefabricated body on the inner template of the mold provided in the above embodiment;

[0070] Step 3, laying the diversion layer outside the prefabricated body;

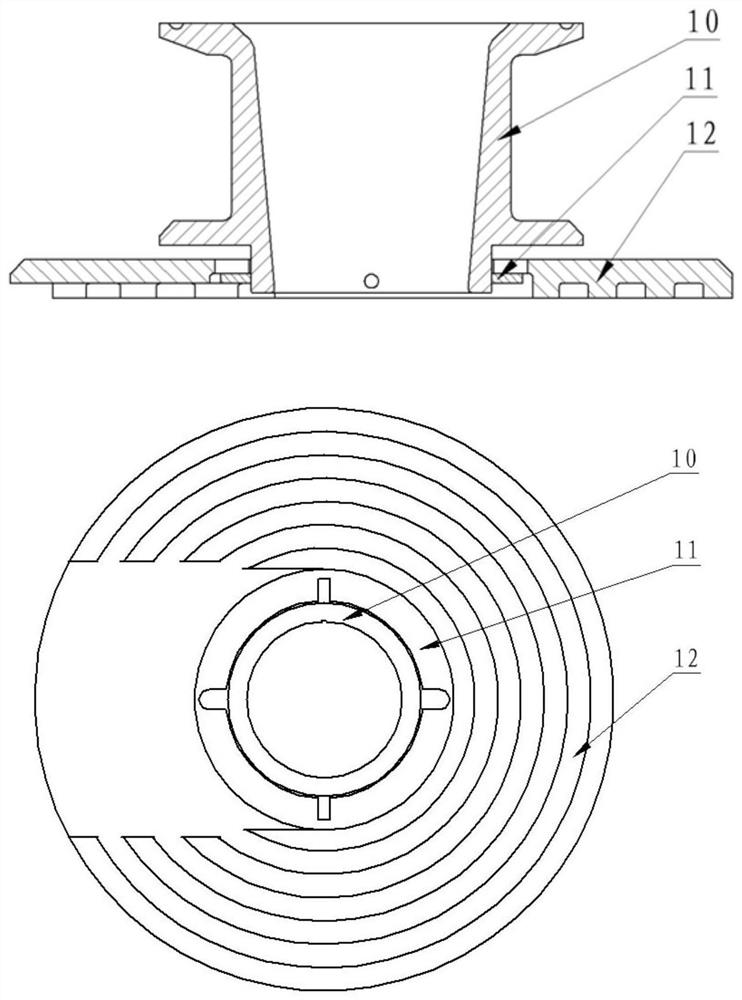

[0071] Step 4, laying the flexible outer film layer on the diversion layer, installing the inlet / outlet nozzle, and then sealingly connecting the flexible outer film layer with the bottom plate to form a closed system;

[0072] Step 5, first vacuumize through the glue outlet, and then enter the shaped resin glue through the ...

Embodiment

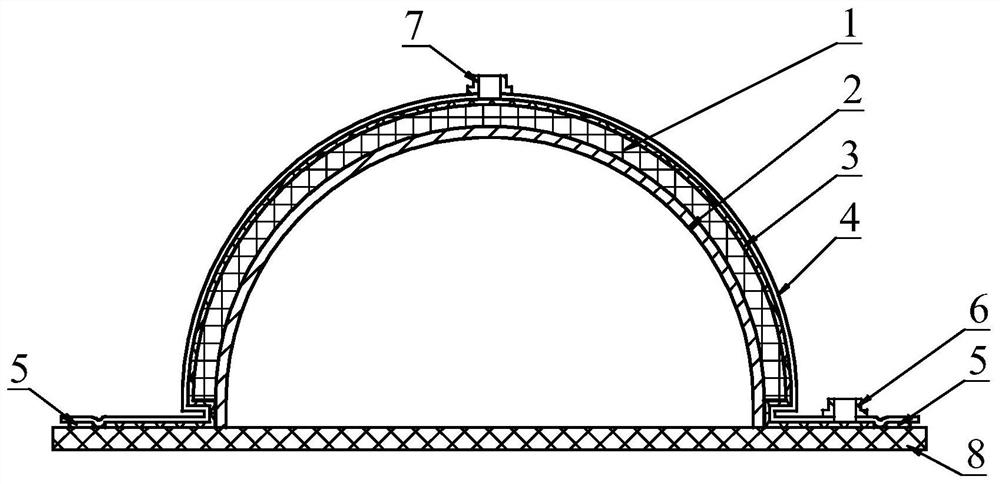

[0087] as attached Figure 4 As shown, the three-dimensional acupuncture process is used to prepare a plate-shaped three-dimensional prefabricated body 1 with an inner diameter of R2200mm, a thickness of 50mm, a width of 1000mm, and a chord length of 1500mm. The inner template 2 is cast aluminum alloy, the outer diameter is R2200mm, the width is 1000mm, and the height is 500mm. The distance between the lowest point of the arc-shaped three-dimensional prefabricated body 1 and the bottom plate 8 is 150mm;

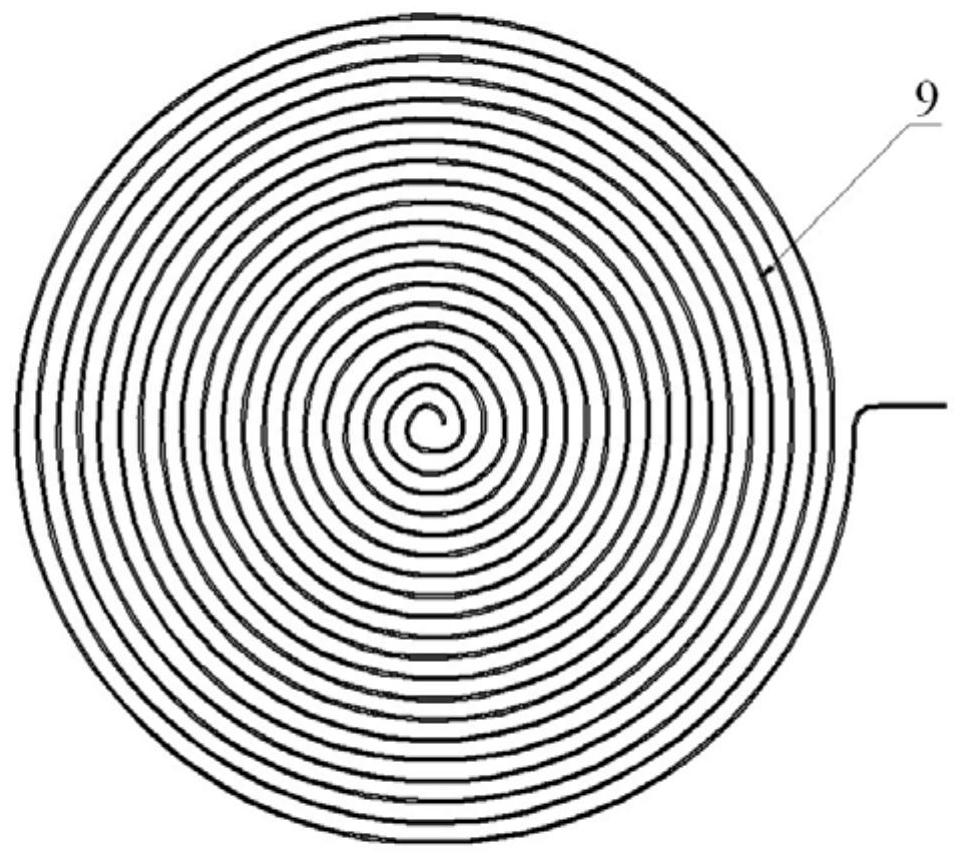

[0088] Lay diversion layer 3 on the surface of arc-shaped three-dimensional prefabricated body 1, as attached Figure 5 As shown, the diversion layer 3 is composed of six sets of coils, three sets of coils on the left and right sides of the arc of the three-dimensional prefabricated body, and each set of coils starts from the central vertex of the arc and is placed in circles along the arc surface. Each connected two coils are fixed with rubber bands or tapes. The coils are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com