Method for manufacturing color photovoltaic device by using water-soluble film and color photovoltaic device

A water-soluble film and color photovoltaic technology, which is applied in the printing of special varieties of printed matter, the process for producing decorative surface effects, climate sustainability, etc., can solve the problem of short service life of patterns, low work efficiency, and economic costs and other problems, to achieve the effect of eliminating disassembly and splicing, improving work efficiency and ensuring printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

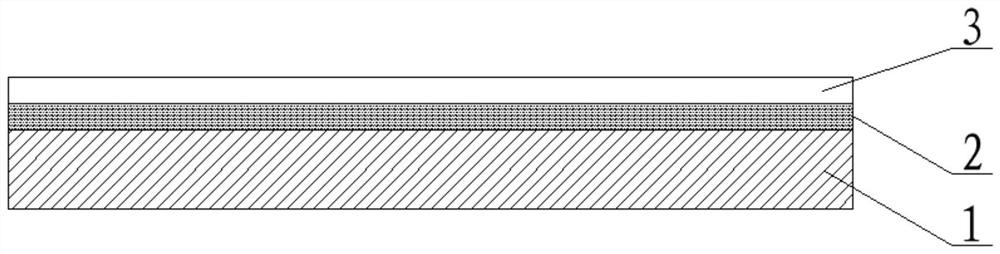

[0057] A method for making a color photovoltaic by utilizing a water-soluble film, comprising the following steps:

[0058] S1: print the pattern on the water-soluble film carrier to form a color layer;

[0059] S2: Spread the printed water-soluble film carrier on the water surface;

[0060] S3: waiting for the water-soluble film to dissolve in water and separate from the color layer;

[0061] S4: Move the unprinted photovoltaic module and the color layer from a vertical angle to a horizontal angle, and adsorb the color layer on the appearance surface of the photovoltaic module;

[0062] S5: The printed photovoltaic module is left to dry until the color layer is completely dry.

[0063] S6: Coat a protective layer on the surface of the color layer.

[0064] S7: UV curing the protective layer.

[0065] In step 1, the water-soluble film carrier is a PVA film.

[0066] In step 1, the film thickness of the water-soluble film carrier is 25 μm.

[0067] In step 1, during the p...

Embodiment 2

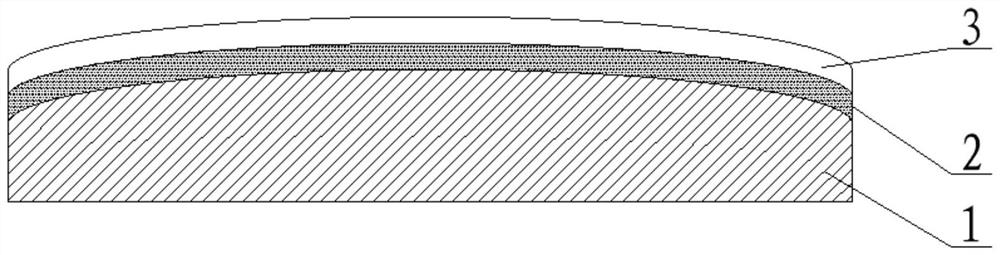

[0071] A method for making a color photovoltaic by utilizing a water-soluble film, comprising the following steps:

[0072] S1: print the pattern on the water-soluble film carrier to form a color layer;

[0073] S2: Spread the printed water-soluble film carrier on the water surface;

[0074] S3: waiting for the water-soluble film to dissolve in water and separate from the color layer;

[0075] S4: Move the unprinted photovoltaic module and the color layer from a vertical angle to a horizontal angle, and adsorb the color layer on the appearance surface of the photovoltaic module;

[0076] S5: Use hot air above 80°C to dry the color layer until it is completely dry;

[0077] S6: Coat a protective layer on the surface of the color layer.

[0078] In step 1, the water-soluble film carrier is a PVA film.

[0079] In step 1, the film thickness of the water-soluble film carrier is 25 μm.

[0080] In step 1, during the pattern printing process, the amount of white ink used per sq...

Embodiment 3

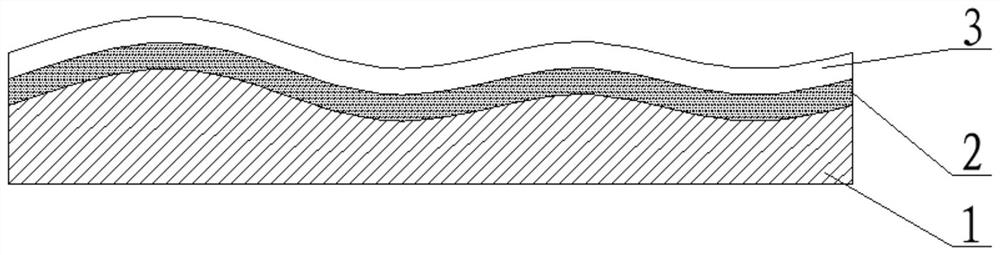

[0084] A method for making a color photovoltaic by utilizing a water-soluble film, comprising the following steps:

[0085] S1: print the pattern on the water-soluble film carrier to form a color layer;

[0086] S2: Spread the printed water-soluble film carrier on the water surface;

[0087] S3: waiting for the water-soluble film to dissolve in water and separate from the color layer;

[0088] S4: Move the unprinted photovoltaic module and the color layer from a vertical angle to a horizontal angle, and adsorb the color layer on the appearance surface of the photovoltaic module;

[0089] S5: Use hot air above 80°C to dry the color layer until it is completely dry;

[0090] S6: Coat a protective layer on the surface of the color layer.

[0091] In step 1, the water-soluble film carrier is a PVA film.

[0092] In step 1, the film thickness of the water-soluble film carrier is 25 μm.

[0093] In step 1, during the pattern printing process, the amount of white ink used per sq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com