Product manufacturing method adopting shrinkable sleeve to reduce or avoid object surface finishing procedure

A technology for object surface and modification process, which is applied in the direction of biological packaging, sustainable manufacturing/processing, closure, etc., and can solve the problems of affecting workers' operation and health, bursting, and many modification processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

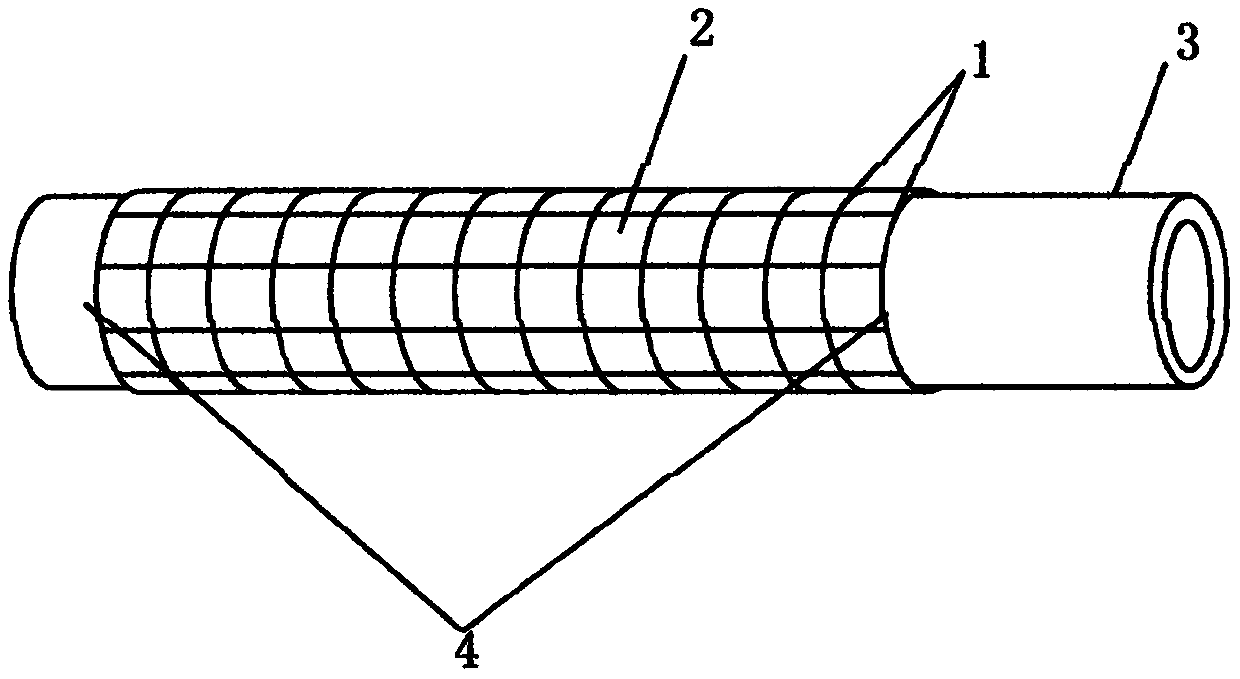

[0018] Such as figure 1 As shown, the outer surface of the shrink sleeve 1 is provided with a laser block 2, and the shrink sleeve 1 is placed on the area where the surface of the plastic tube 3 is coated with glue 4. If the shrink sleeve 1 is shrunk and tightly wrapped around the plastic tube 3 by heating, The plastic tube 3 is equivalent to changing a coat, which will produce a new visual effect. This method is more simple and convenient than painting and electroplating. Even if there are wounds, cracks or stains and old traces that cannot be wiped off on the surface of the plastic pipe 3, there is no need to increase grinding and repair processes. In this way, it can bring convenience to the decoration work.

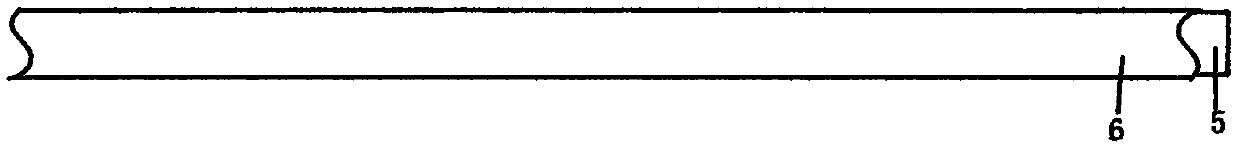

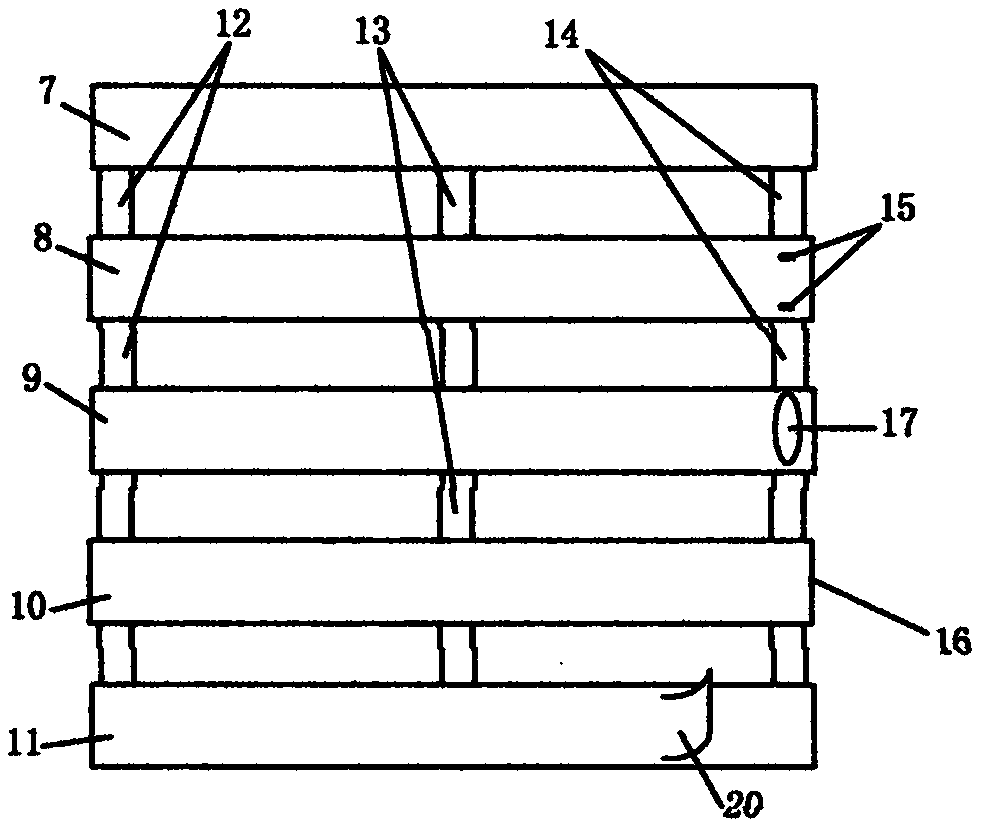

[0019] combine figure 2 , image 3 Shown, the mode of making product is: the first step: plank 5 is sawed into the strip shape of required width and thickness. Step 2: Insert the strip-shaped wooden board 5 into the shrink sleeve 6 of corresponding specification....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com