Process method for producing extensible paper bag paper with high strength and high air permeability

A process method and paper bag technology, which is applied in the field of paper bag paper, can solve the problems of reducing the performance of paper bag paper, such as tensile strength and energy absorption, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

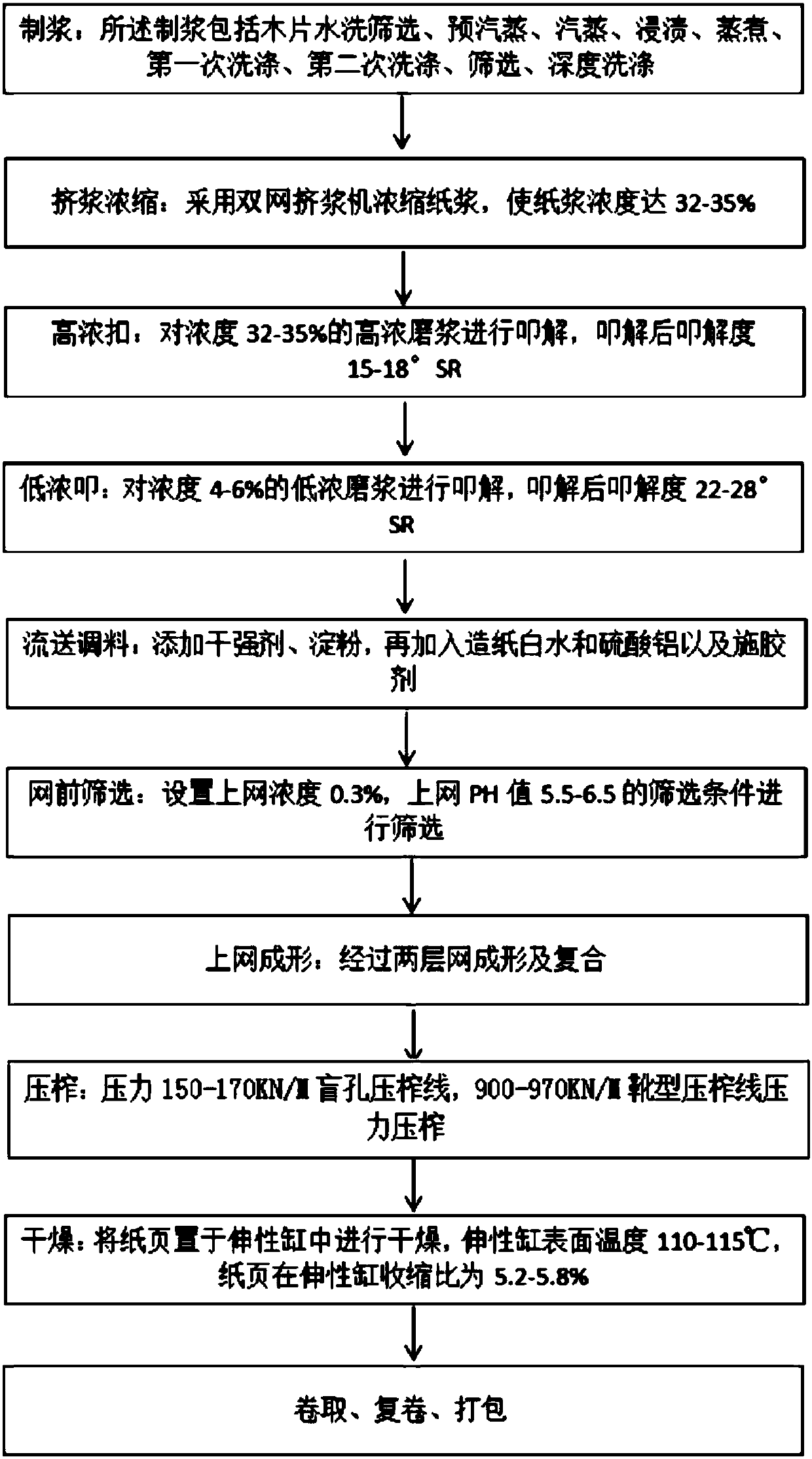

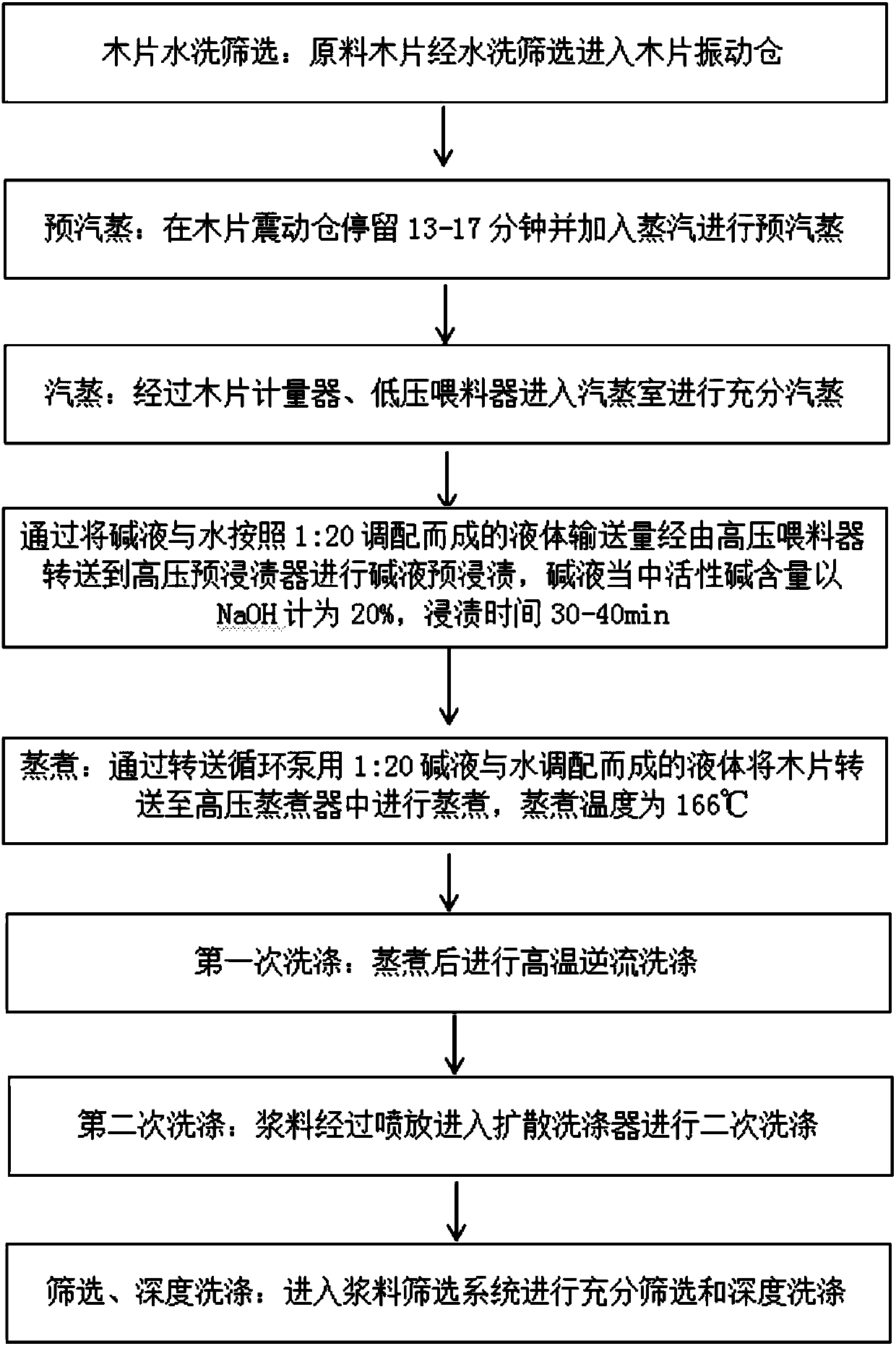

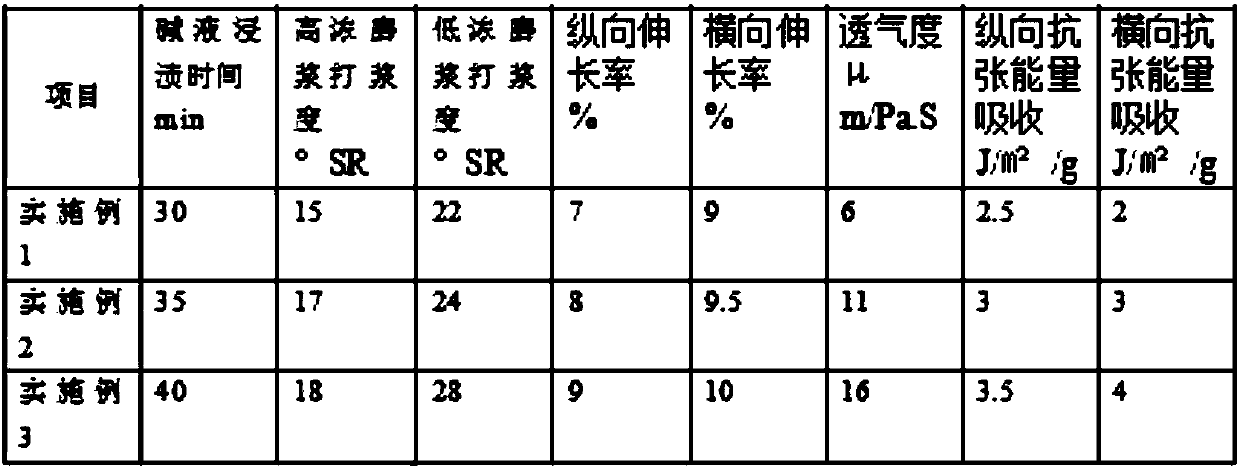

[0039] Such as figure 1 , figure 2 , image 3 Shown: The coniferous wood chips are washed and screened into the wood chip vibrating bin, stay for 13-17 minutes and add steam for pre-steaming, and then enter the steaming chamber through the wood chip meter and low-pressure feeder for full steaming, and then pass the lye The liquid delivery volume of a certain liquid ratio prepared with water according to the weight ratio of 1:20 is transferred to the high-pressure prepregr %, and then the wood chips are transferred to the high-pressure cooker for cooking and high-temperature countercurrent washing through the transfer circulation pump with a certain proportion of liquid prepared by lye and water with a weight ratio of 1:20. The cooking temperature is 166 ° C. After spraying Put it into the diffusion washer for secondary washing, and finally enter the pulp screening system for full screening and deep washing, and then send the qualified pulp to the pulp storage tower for pape...

Embodiment 2

[0043] Such as figure 1 , figure 2 , image 3 Shown: The coniferous wood chips are washed and screened into the wood chip vibrating bin, stay for 13-17 minutes and add steam for pre-steaming, and then enter the steaming chamber through the wood chip meter and low-pressure feeder for full steaming, and then pass the lye The liquid delivery volume of a certain liquid ratio prepared with water according to the weight ratio of 1:20 is transferred to the high-pressure prepregr %, and then the wood chips are transferred to the high-pressure cooker for cooking and high-temperature countercurrent washing through the transfer circulation pump with a certain proportion of liquid prepared by lye and water with a weight ratio of 1:20. The cooking temperature is 166 ° C. After spraying Put it into the diffusion washer for secondary washing, and finally enter the pulp screening system for full screening and deep washing, and then send the qualified pulp to the pulp storage tower for pape...

Embodiment 3

[0047] Such as figure 1 , figure 2 , image 3 Shown: The coniferous wood chips are washed and screened into the wood chip vibrating bin, stay for 13-17 minutes and add steam for pre-steaming, and then enter the steaming chamber through the wood chip meter and low-pressure feeder for full steaming, and then pass the lye The liquid delivery volume of a certain liquid ratio prepared with water according to the weight ratio of 1:20 is transferred to the high-pressure prepregr %, and then the wood chips are transferred to the high-pressure cooker for cooking and high-temperature countercurrent washing through the transfer circulation pump with a certain proportion of liquid prepared by lye and water with a weight ratio of 1:20. The cooking temperature is 166 ° C. After spraying Put it into the diffusion washer for secondary washing, and finally enter the pulp screening system for full screening and deep washing, and then send the qualified pulp to the pulp storage tower for paper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal elongation | aaaaa | aaaaa |

| Longitudinal elongation | aaaaa | aaaaa |

| Longitudinal elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com