Surface light source

A surface light source and yellow fluorescent technology, applied in the field of surface light source, can solve the problems of small luminous area of line light source, high photobiological hazard value, and large photoradiation hazard, so as to reduce the value of photobiological hazard index, improve visual comfort, Improve the effect of lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

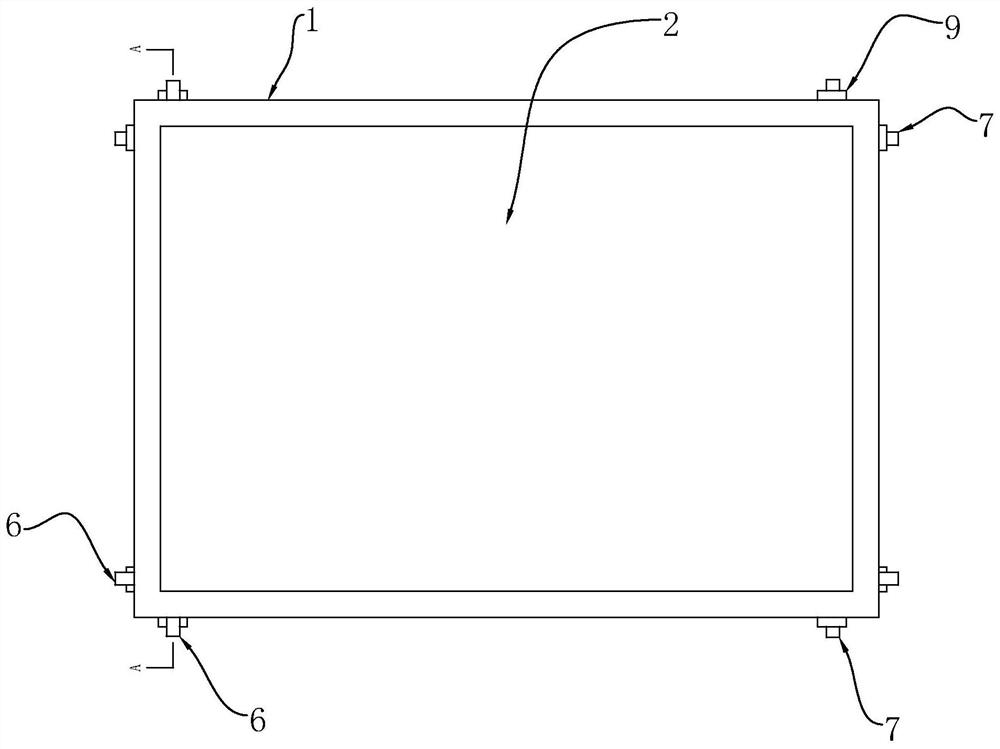

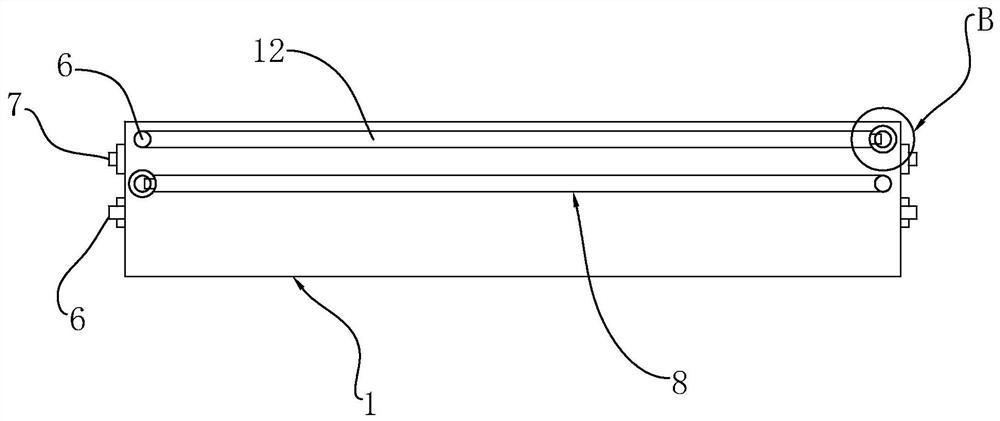

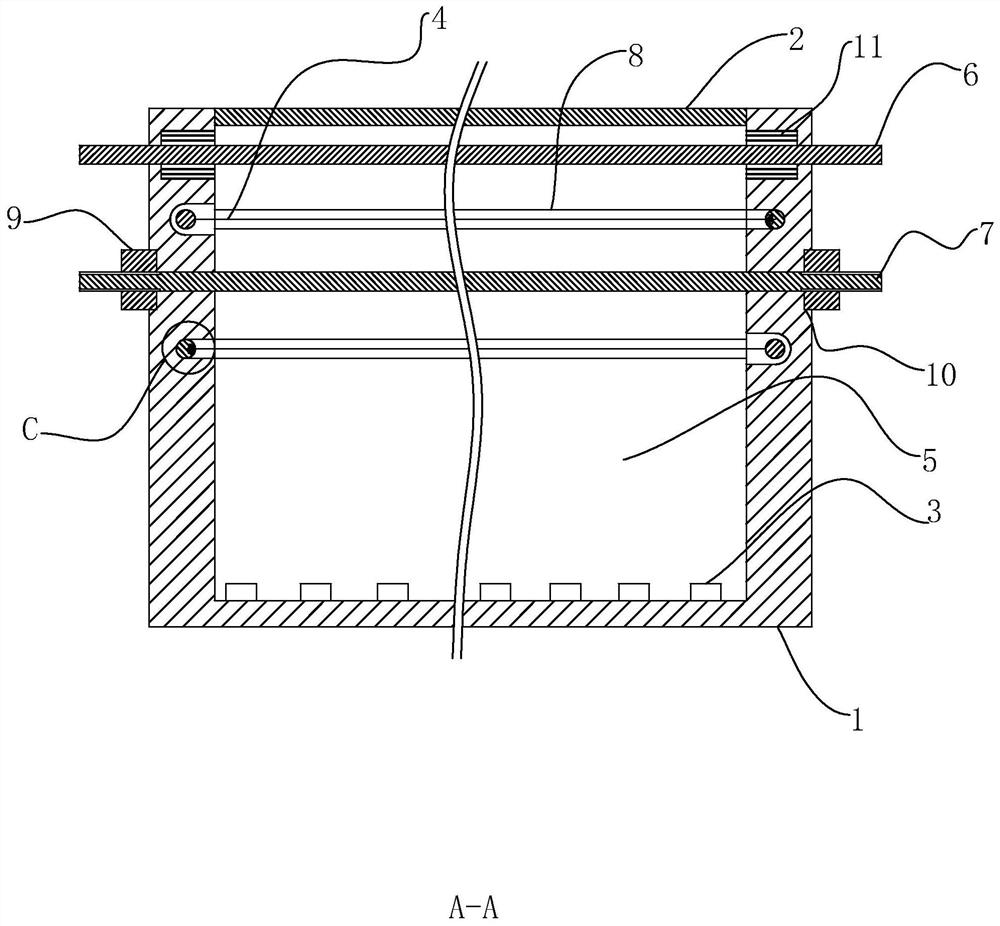

[0028] A surface light source such as figure 1 and image 3 As shown, it includes a rectangular parallelepiped base 1, a lampshade 2 and a white luminous body 3 arranged in the lampshade 2, and a mounting groove 5 is provided in the base 1, and 4 pieces of yellow fluorescent films 4 are arranged in the mounting groove 5, according to Components in parts by weight The yellow fluorescent film 4 includes 0.1% yellow fluorescent powder, 10% diffusion masterbatch and 89.9% transparent engineering plastic particles, and the particle size of the yellow fluorescent powder is 1um.

[0029]

[0030] Table 1 is the data comparison between low blue light LED lamps and ordinary LED lamps

[0031] Four winding rollers 6 are rotated around the base 1, and the four winding rollers 6 are respectively extended to the outside of the base 1. Each yellow fluorescent film 4 is wound on the corresponding winding roller 6 and one end is connected to The winding rollers 6 are fixed to each other....

Embodiment 2

[0036]The main difference from Embodiment 1 is: a surface light source, including a cuboid base 1, a lampshade 2 and a white luminous body 3 arranged in the lampshade 2, and a mounting groove 5 is provided in the base 1, and the mounting groove 5 There are 4 pieces of yellow fluorescent film 4 inside, and the yellow fluorescent film 4 described in parts by weight includes 1% yellow fluorescent powder, 15% diffusion masterbatch and 84% transparent engineering plastic particles, yellow fluorescent powder The particle size is 2um.

Embodiment 3

[0038] The main difference from Embodiment 1 is: a surface light source, including a cuboid base 1, a lampshade 2 and a white luminous body 3 arranged in the lampshade 2, and a mounting groove 5 is provided in the base 1, and the mounting groove 5 There are 4 pieces of yellow fluorescent film 4 inside. The yellow fluorescent film 4 described in parts by weight includes 1.5% yellow fluorescent powder, 20% diffusion masterbatch and 78.5% transparent engineering plastic particles, yellow fluorescent powder The particle size is 3um.

[0039] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com