LED substrate, LED and packaging method of LED

A technology of LED substrates and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of weak resistance to moisture ingress and shortened service life of LED encapsulation adhesives, and achieve enhanced machine placement yield, The effect of improving the binding force and improving the ability to resist moisture ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

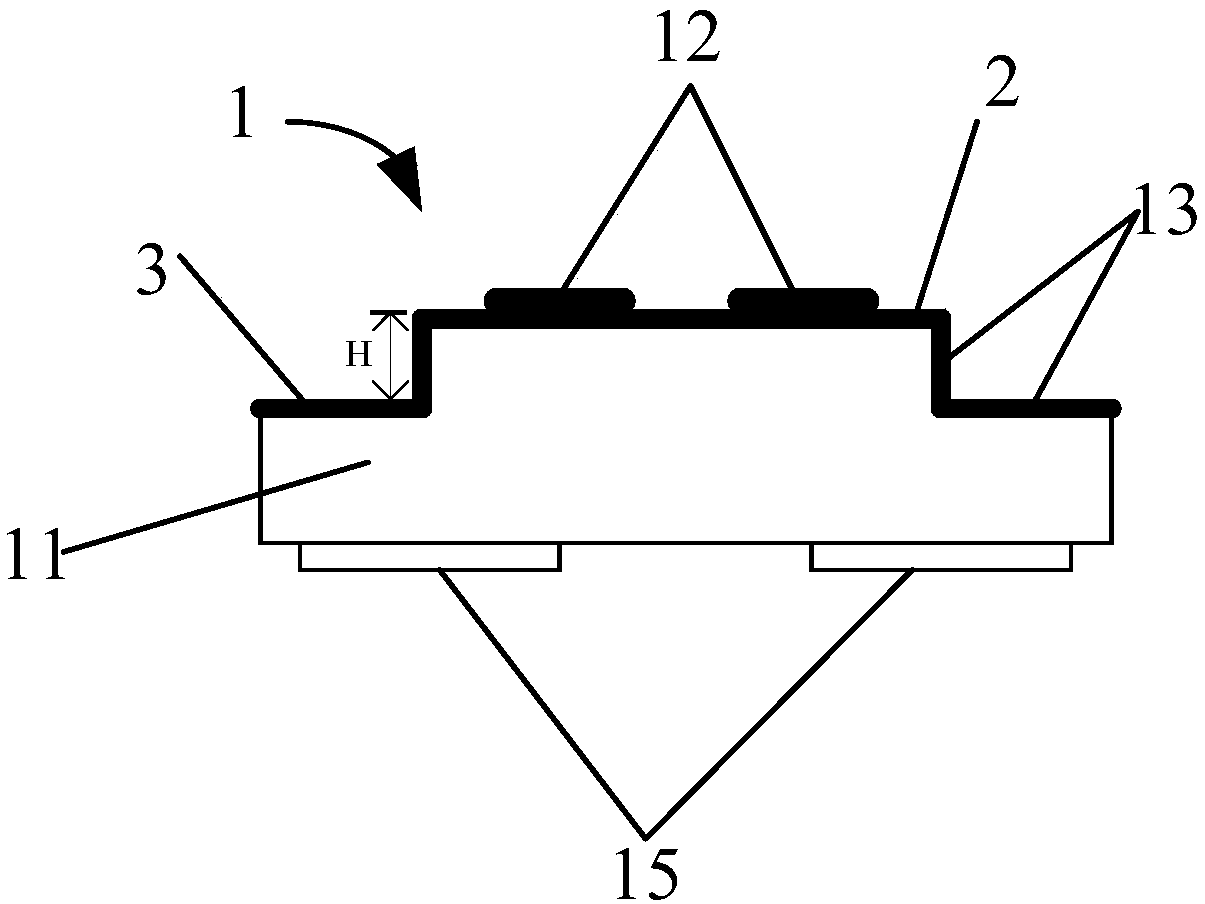

[0031] Aiming at the problem in the prior art that the ability of the LED encapsulant to resist moisture ingress becomes weaker after the solid-type encapsulation is completed due to the reduction in the size of the LED, the present invention provides a solution by prolonging the bond between the encapsulant and the substrate body. Surface area to improve the moisture resistance of the encapsulant. Specifically, the present invention provides a LED substrate, see figure 2 , the LED substrate 1 includes a substrate body 11, and the substrate body 11 includes at least two planes with a difference between them. Preferably, in this embodiment, two planes are set on the substrate body 11 as an example for illustration, and the set The height difference H between the two planes is greater than zero, and it can be understood that the height difference here refers to the vertical distance between the two planes.

[0032] In this embodiment, the substrate body 11 also includes a copp...

Embodiment 2

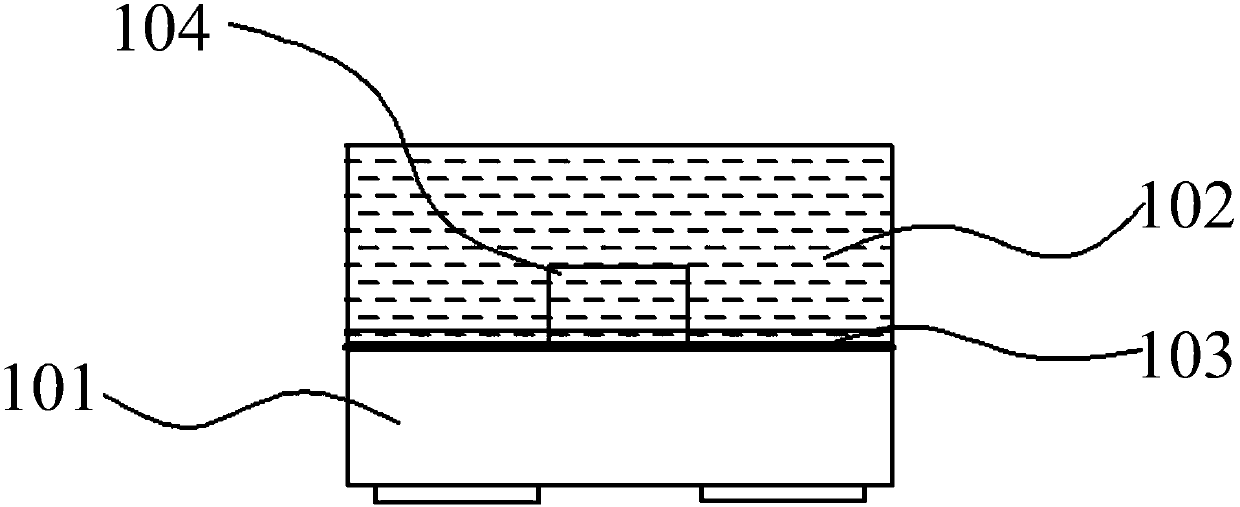

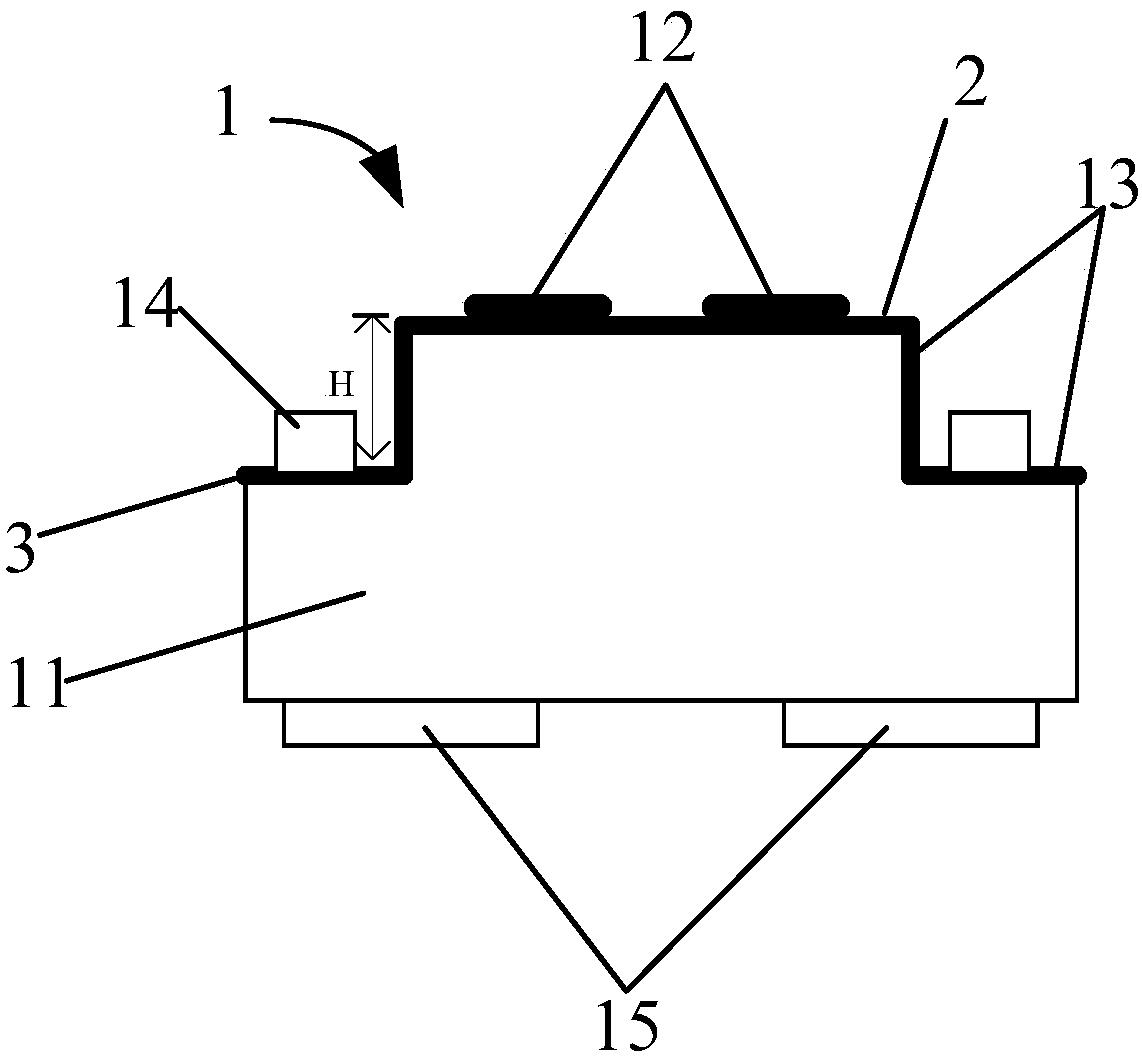

[0044] Please refer to Figure 8 , Figure 8 It is a schematic structural diagram of an LED provided by the present invention. The LED specifically includes an LED chip 21, an encapsulant 22 and an LED substrate 1. Preferably, the LED substrate 1 is the LED substrate provided in the first embodiment above. The LED substrate 1 includes a substrate body 11, and a copper-clad area 12 and a packaging area 13 on the substrate body, wherein the substrate body 11 specifically includes at least two planes with a difference between each other, and the copper-clad area 12 and the packaging area 13 respectively arranged on these two planes; the LED chip 21 is welded on the copper clad area 12 on the LED substrate 1, and the encapsulation glue 22 is pressed onto the encapsulation area 13 by a molding process to be solidified, The LED chip 21 is sealed on the LED substrate 1 .

[0045] In this embodiment, at least one geometric step 14 is also provided on the area corresponding to the pa...

Embodiment 3

[0049] See Figure 9 , Figure 9 It is a flow chart of the LED packaging method provided by the present invention. The LED provided in this embodiment includes an LED substrate 1, an LED chip 21 and an encapsulation glue 22, wherein the LED substrate 1 is provided with at least two planes that are not on the same horizontal line , and a copper-clad area and a packaging area are correspondingly provided on these two planes, the copper-clad area is used for soldering the LED chip 21, and the packaging area is used to carry the solid type of packaging glue 22 and fix it on the In order to realize the sealing of the LED chip 21 on the packaging area, in order to adapt to the production and manufacture of the LED, the present invention provides a manufacturing method that can extend the area of the bonding surface between the packaging glue and the LED substrate. Specifically, the packaging The implementation steps of the method include:

[0050] S901, setting at least two plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com