Non-aqueous inkjet ink composition

An ink composition, non-aqueous technology, applied in inks, applications, household appliances, etc., can solve the problems of waste liquid pipe occlusion, deformation, fine printing bleeding, etc., achieve low viscosity, good resolubility, and prevent spot occurrence sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

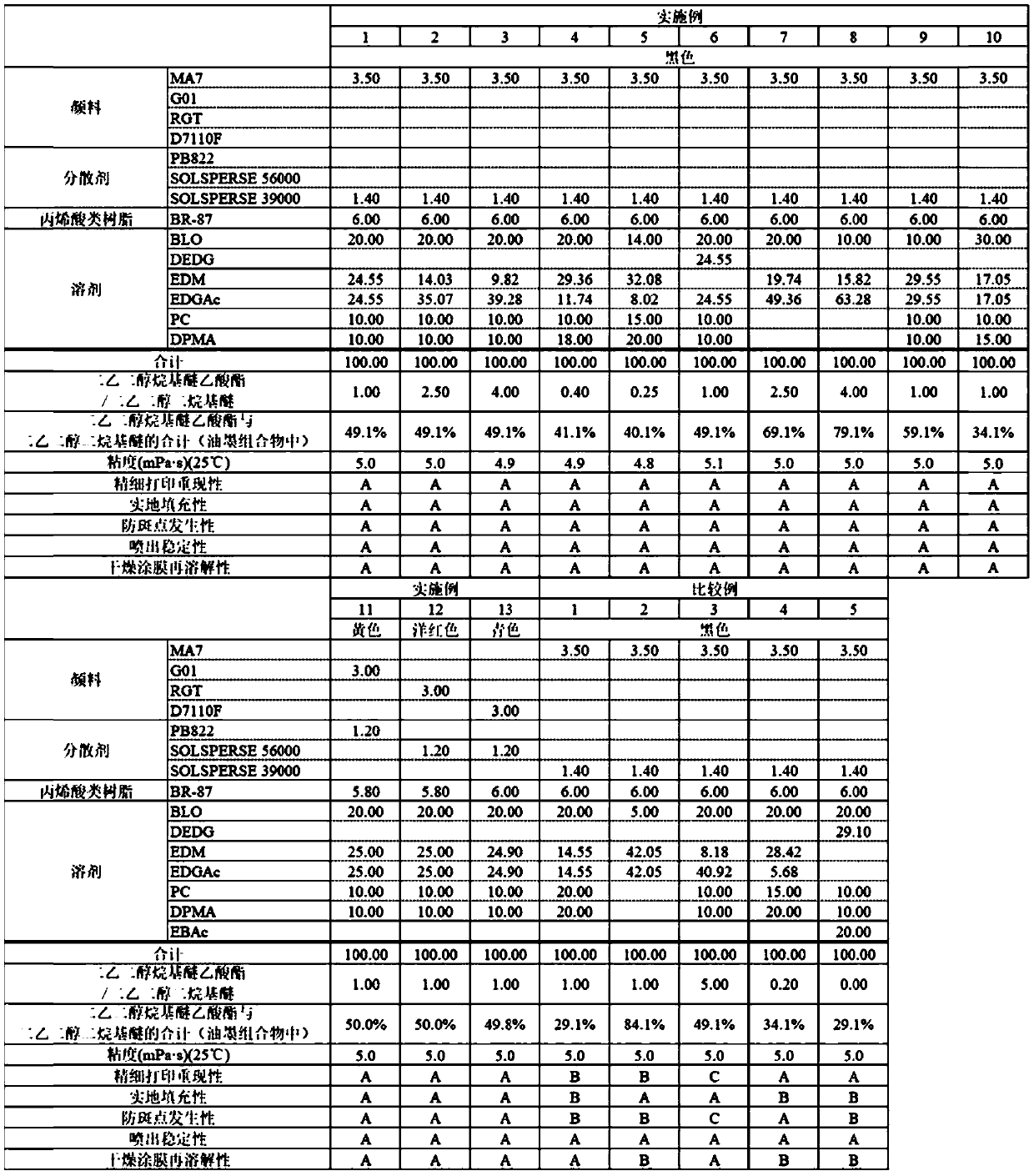

Embodiment 1~13 and comparative example 1~5

[0088] (manufacturing of various color matrix inks)

[0089]

[0090] Dissolve 10 parts of a pigment dispersant (SOLSPERSE 39000) in 65 parts of EDM (DEDG in Example 6), stir and mix 25 parts of a pigment (MA7) therein, and grind with a bead mill to obtain matrix black for non-aqueous inkjet ink.

[0091]

[0092] 10 parts of a pigment dispersant (SOLSPERSE 56000) was dissolved in 65 parts of EDM, 25 parts of a pigment (D7110F) was stirred and mixed therein, and then ground with a bead mill to obtain a base cyan ink for non-aqueous inkjet.

[0093]

[0094] 10 parts of a pigment dispersant (PB822) was dissolved in 65 parts of EDM, 25 parts of a pigment (G01) was stirred and mixed therein, and then ground with a bead mill to obtain a base yellow ink for non-aqueous inkjet.

[0095]

[0096] 10 parts of a pigment dispersant (SOLSPERSE 56000) was dissolved in 65 parts of EDM, 25 parts of a pigment (RGT) was stirred and mixed therein, and the ink was ground using a bead m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com