High-pressure electrostatic oil removal device

A high-voltage electrostatic and electrostatic wire technology, applied in the field of VOC waste gas treatment, can solve the problems such as air inlet and outlet can only be set on the side wall of the electrostatic outer tube, short service life, easy to pollute the electrostatic wire, etc., to avoid breakdown Discharge phenomenon, good degreasing effect, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

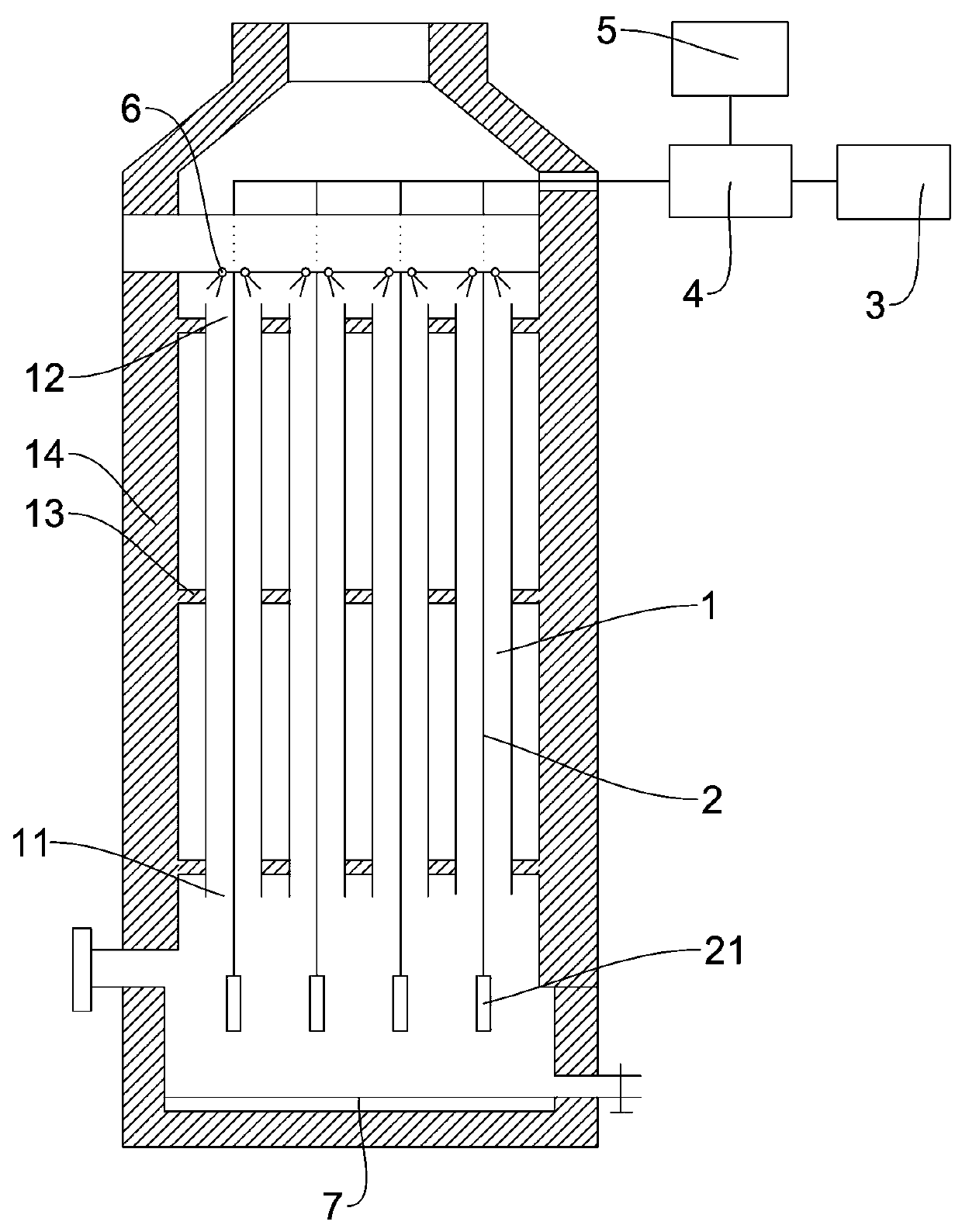

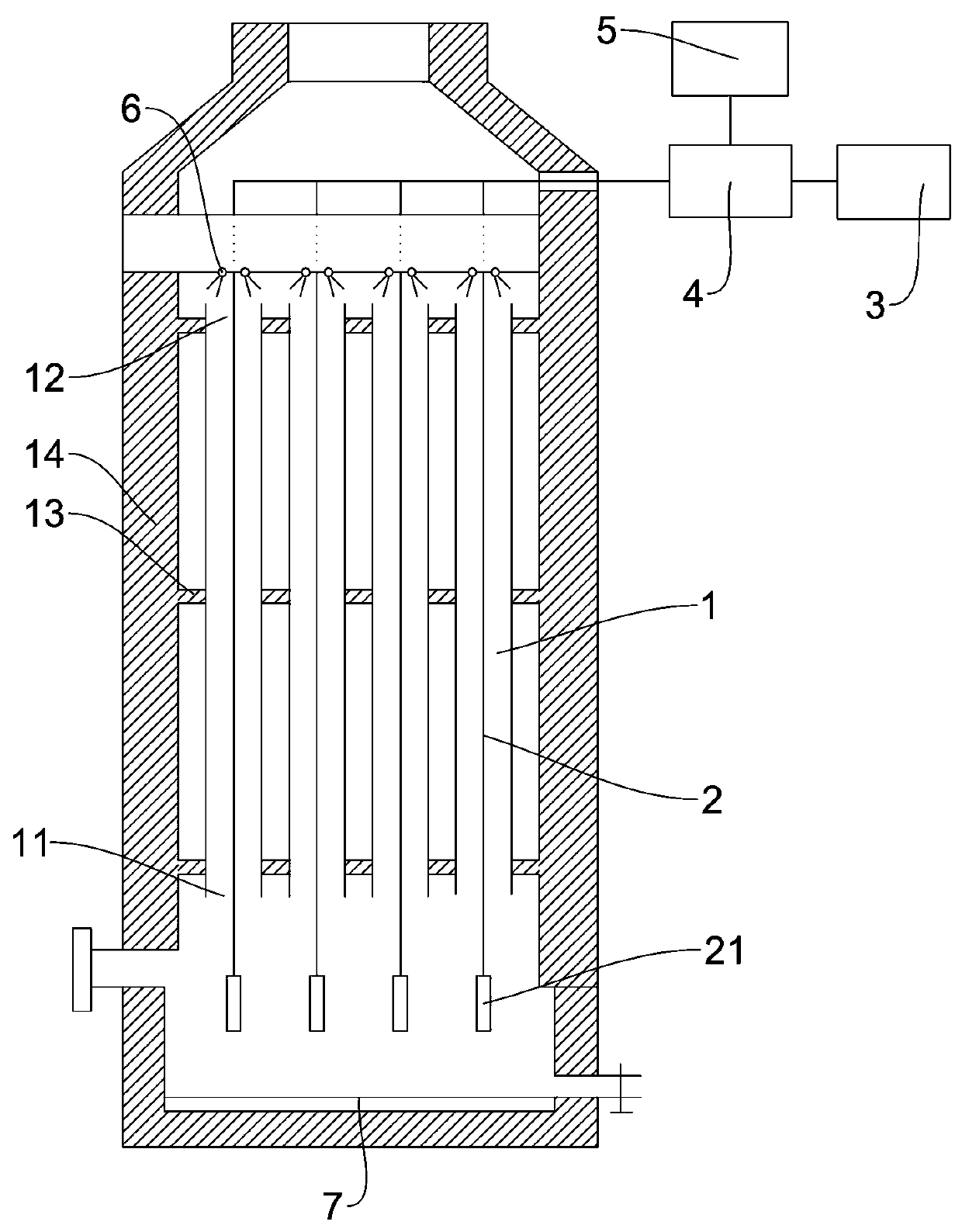

[0030] A high-voltage electrostatic oil removal device is used to remove oily particles in dry waste gas, especially suitable for the treatment of high-temperature foaming waste gas. Such as figure 1 As shown, it includes an exhaust gas pipe 1 with an air inlet 11 and an air outlet 12 on both ends, and the exhaust gas pipe 1 is provided with a power supply 3 through a step-up transformer 4 to generate 40,000-75,000 volts in the exhaust gas pipe 1. Electrostatic wire 2 for high voltage electrostatic field. The step-up transformer 4 is also connected with a voltage regulator 5 for adjusting the voltage value.

[0031] In this example, it is used to remove VOC oil particles from the 90-115°C waste gas generated by the foaming fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com