High-stripping-resistance electrolytic copper foil with uniform microscopic surface particles and preparation method of high-stripping-resistance electrolytic copper foil

A technology of electrolytic copper foil and copper foil, which is applied in the field of high anti-stripping electrolytic copper foil and its preparation, can solve the problems of uneven particle size of the plating layer, short circuit of the circuit, and residual copper, etc. Strength, the effect of increasing the adhesion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

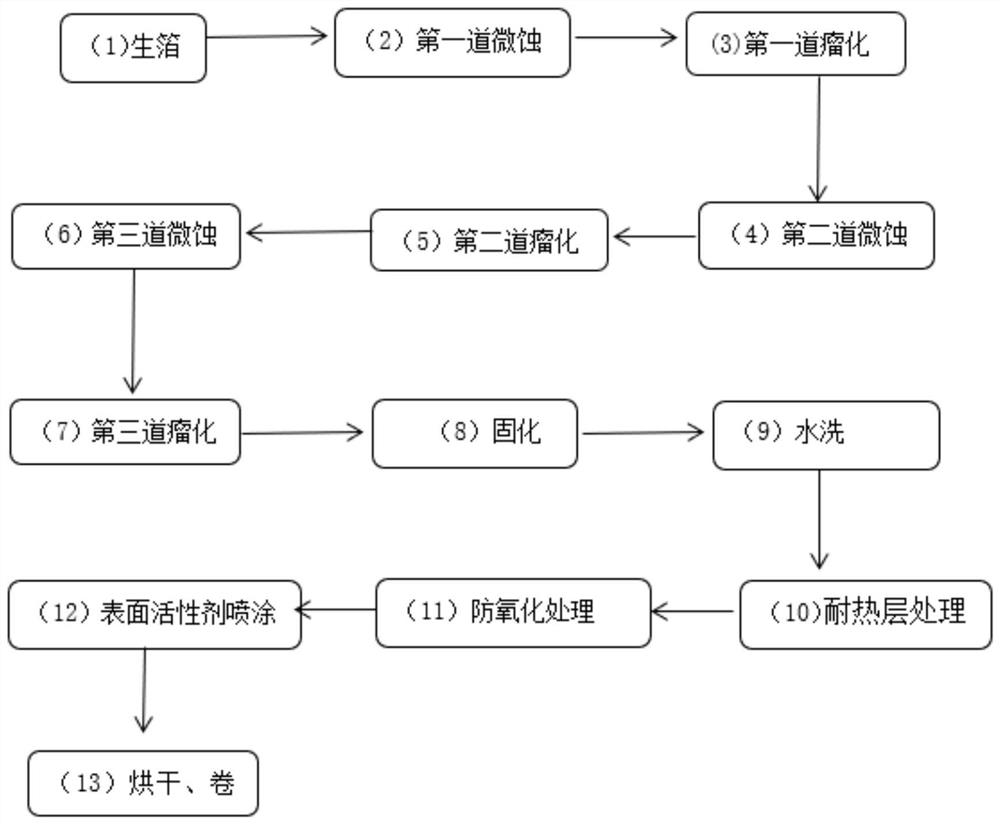

[0047] A high anti-stripping electrolytic copper foil with uniform microscopic surface particles, the preparation method of the electrolytic copper foil specifically comprises the following steps:

[0048] (1) use the micro-etching solution A to carry out the first micro-etching treatment on the copper foil, and then use the electrolyte to carry out the electrodeposition of the first copper nodule layer to obtain the material A;

[0049] (2) using the micro-etching solution B to carry out the second micro-etching treatment of the material A, and then using the electrolyte to carry out the electrodeposition of the second copper nodule layer to obtain the material B;

[0050] (3) use the micro-etching solution C to carry out the third micro-etching process on the material B, and then use the electrolyte to carry out the third copper-nodularized layer electrodeposition, to obtain the copper-nodularized layer;

[0051] (4) carrying out surface curing treatment, washing with water,...

Embodiment 2

[0059] A high anti-stripping electrolytic copper foil with uniform microscopic surface particles, the preparation method of the electrolytic copper foil specifically comprises the following steps:

[0060] (1) use the micro-etching solution A to carry out the first micro-etching treatment on the copper foil, and then use the electrolyte to carry out the electrodeposition of the first copper nodule layer to obtain the material A;

[0061] (2) using the micro-etching solution B to carry out the second micro-etching treatment of the material A, and then using the electrolyte to carry out the electrodeposition of the second copper nodule layer to obtain the material B;

[0062] (3) use the micro-etching solution C to carry out the third micro-etching process on the material B, and then use the electrolyte to carry out the third copper-nodularized layer electrodeposition, to obtain the copper-nodularized layer;

[0063] (4) carrying out surface curing treatment, washing with water,...

Embodiment 3

[0071] A high anti-stripping electrolytic copper foil with uniform microscopic surface particles, the preparation method of the electrolytic copper foil specifically comprises the following steps:

[0072] (1) use the micro-etching solution A to carry out the first micro-etching treatment on the copper foil, and then use the electrolyte to carry out the electrodeposition of the first copper nodule layer to obtain the material A;

[0073] (2) using the micro-etching solution B to carry out the second micro-etching treatment of the material A, and then using the electrolyte to carry out the electrodeposition of the second copper nodule layer to obtain the material B;

[0074] (3) use the micro-etching solution C to carry out the third micro-etching process on the material B, and then use the electrolyte to carry out the third copper-nodularized layer electrodeposition, to obtain the copper-nodularized layer;

[0075] (4) carrying out surface curing treatment, washing with water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com