Machining technology of two-sided long thin rectangular part

A processing technology and part technology, which is applied to the processing technology field of double-sided slender rectangular parts, can solve the problems of unstable structure, low processing efficiency, easy to vibrate, etc., and achieve the effect of saving clamping time and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

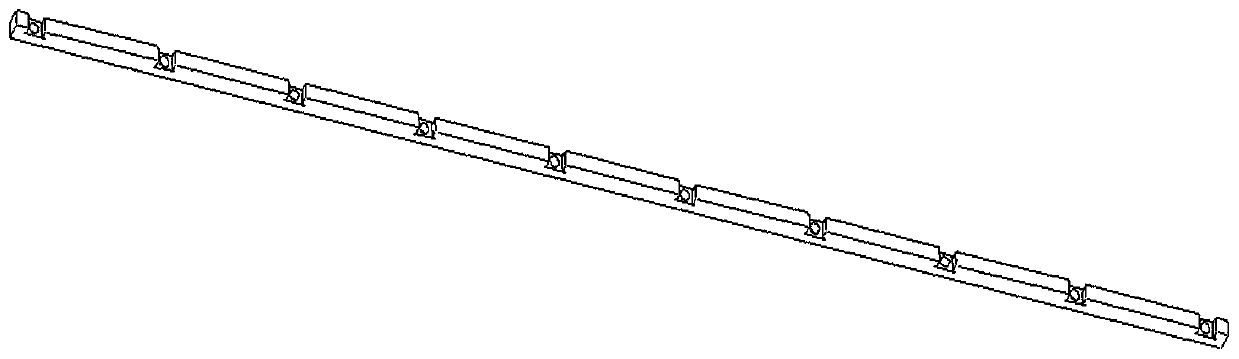

[0030] 1. Double-sided slender rectangular parts (such as figure 1 As shown), there are stations on both the front and back of the part, the width of the part is about 8mm, the thickness is about 11mm, and the length is about 1000mm. The part in the free state is very easy to vibrate and bend.

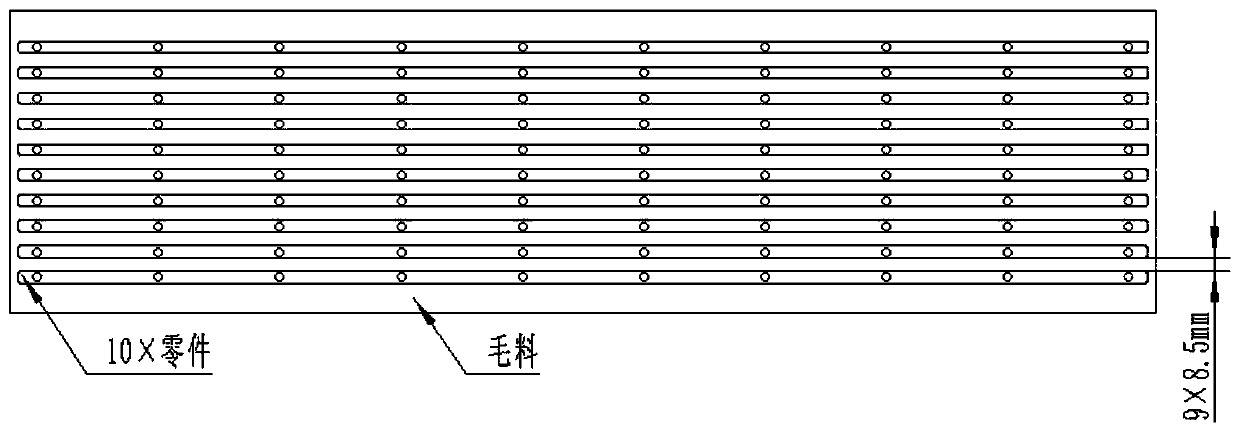

[0031] 2. If figure 2 As shown, 10 parts are arranged in a row, and the distance between the parts is the same as 8.5mm. 1) Use a φ100 disc cutter to mill the upper and lower parts of the part to ensure that the thickness of the part is 11±0.1mm; 2) The front chamfer is 0.4mm, and the φ8mm cutter is used to mill the sinking depth of 1mm (as the avoidance area of the chamfering cutter).

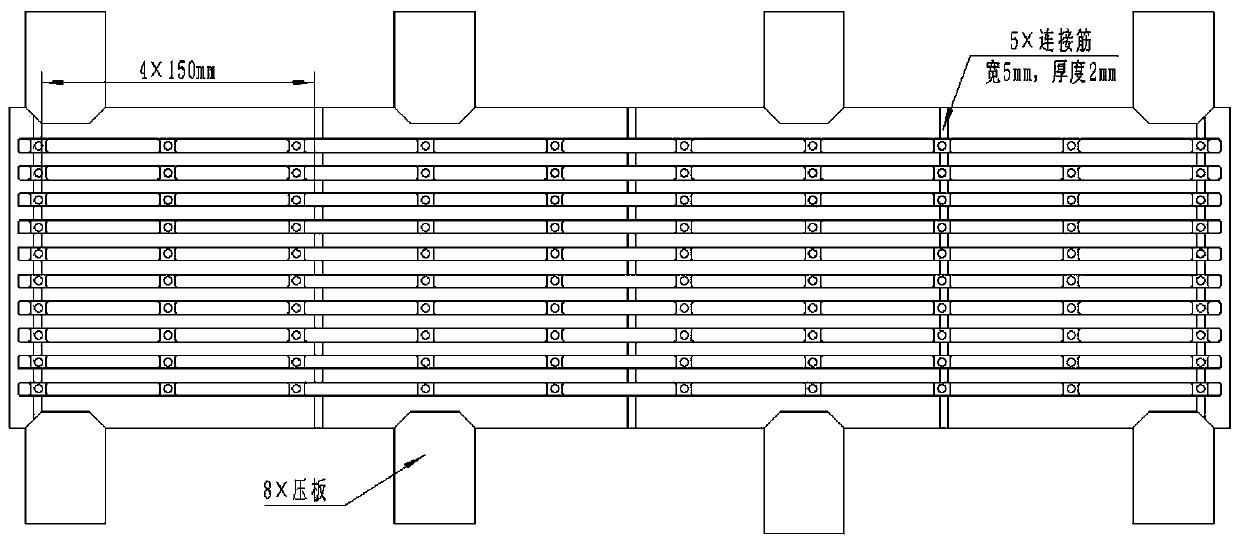

[0032] 3. (such as image 3 As shown) Turn over the entire size of the part to be processed, and reserve the connecting ribs when cutting to avoid parts vibrating and overcutting the parts. The spacing of the connecting ribs is 150mm, the width of the connecting ribs is 5mm, and the thickness is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com