Compression bar contact type tensegrity structure and integration and tension exertion method

A tension-integrated structure and contact-type technology, applied in truss-type structures, special data processing applications, instruments, etc., can solve the problems of low rigidity of the tensioned overall structure, difficulty in installation and integration, and difficult tension, etc., and achieve the tension application method Efficient, geometrically stable and easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

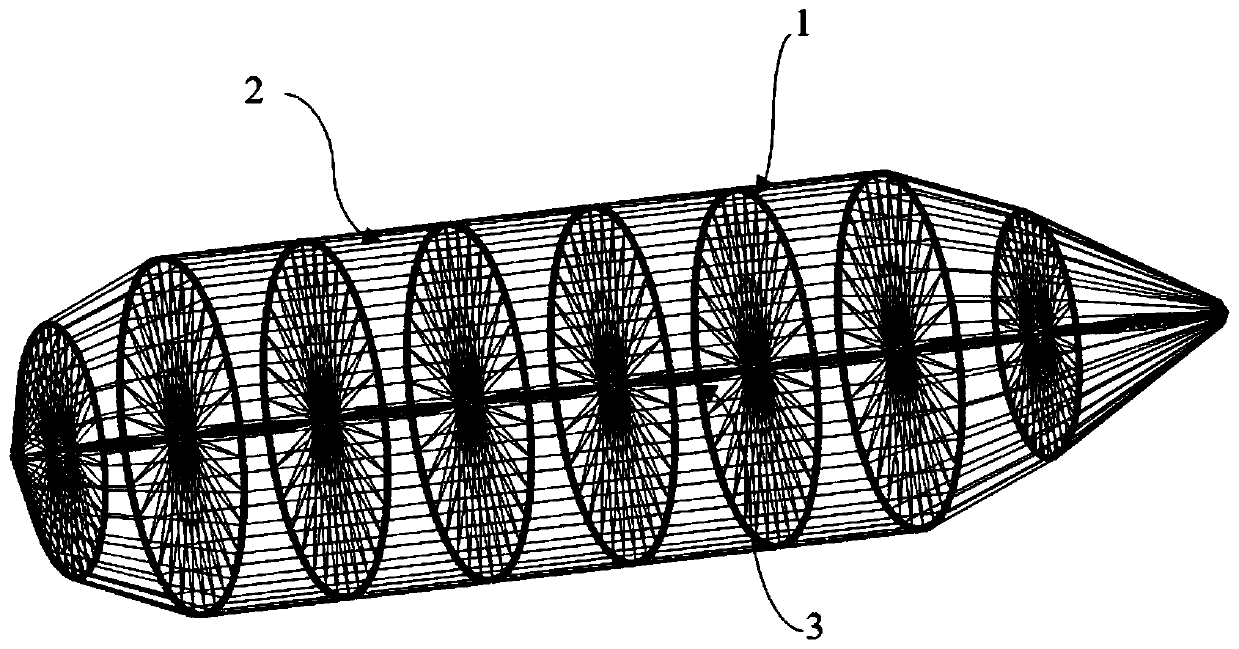

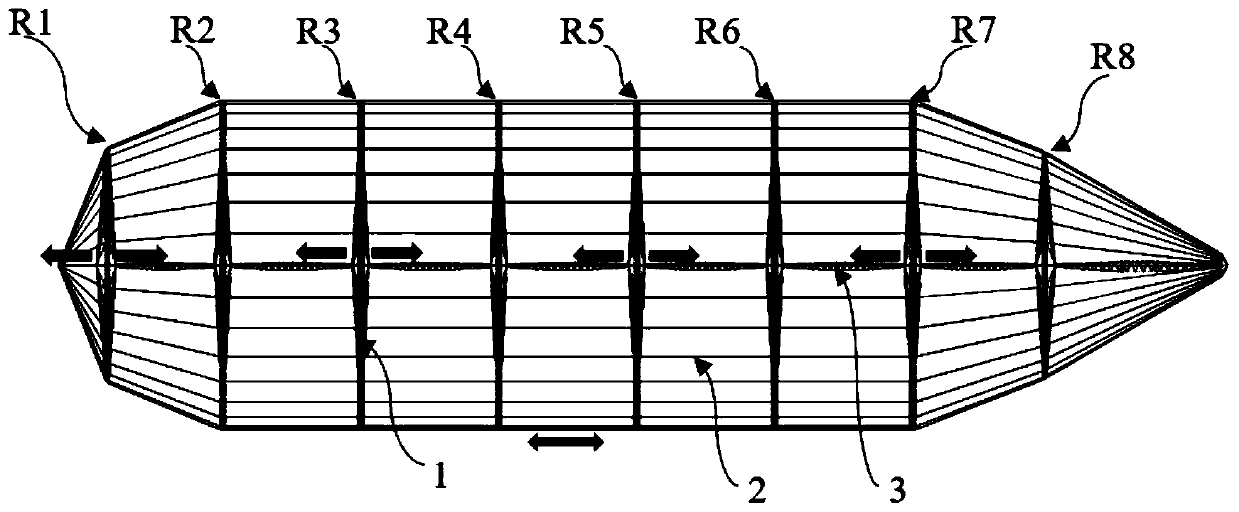

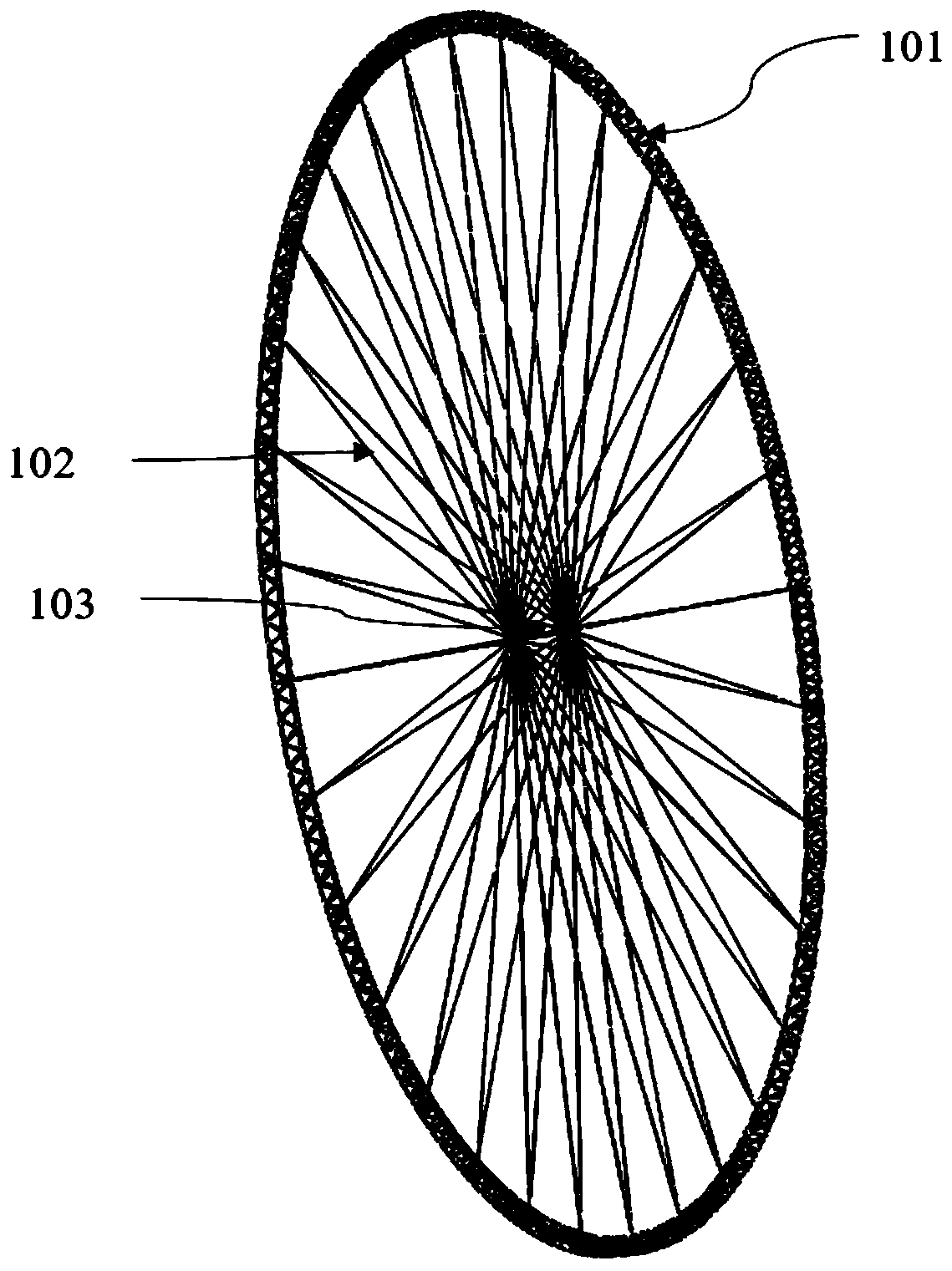

[0042] Such as figure 1 , figure 2 As shown, a preferred embodiment of the present invention provides a three-dimensional schematic diagram of a tension bar contact type tensioned overall structure, which includes a stiffening ring triangular truss 1, a high-strength and high-rigidity longitudinal tie bar 2, a central axis triangular truss 3, and more A stiffening ring triangular truss 1 is isolated under pressure, a plurality of central mandrel triangular trusses 3 are in contact with pressure, and several high-strength and high-rigidity longitudinal tie rods 2 are continuously tensioned to form a self-balancing and self-supporting tensioned overall structure.

[0043] The tensioned overall structure is a combined geometry, the head and tail are conical, the middle section is cylindrical, the middle section of the stiffened ring triangular truss 1 has the same diameter, parallel, and the same spacing, and the stiffened ring triangular truss 1 at both ends has a small diamete...

Embodiment 2

[0058] On the basis of the first embodiment, the high-strength and high-rigidity longitudinal tie rods 2 in the second embodiment are sequentially connected with multiple (5-7) parallel stiffening ring triangular trusses 1 from the outer ring to the tail to form a closed tension ring. The central axis triangular truss 3 is multi-segment (6-8), which are sequentially connected to the hub shafts 103 of multiple (5-7) parallel stiffening ring triangular trusses 1 to form a pressure rod contact type pressure-bearing center from the bow to the stern spindle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com