Universal tail hoisting tool for hoisting wind power tower barrel

A wind power tower, universal technology, applied in the field of large-scale wind turbine tower hoisting, can solve the problems of troublesome locks in the installation and disassembly process, low efficiency, troublesome locks in installation and disassembly, etc., to ensure personal safety, obvious economic benefits, Safe performance and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

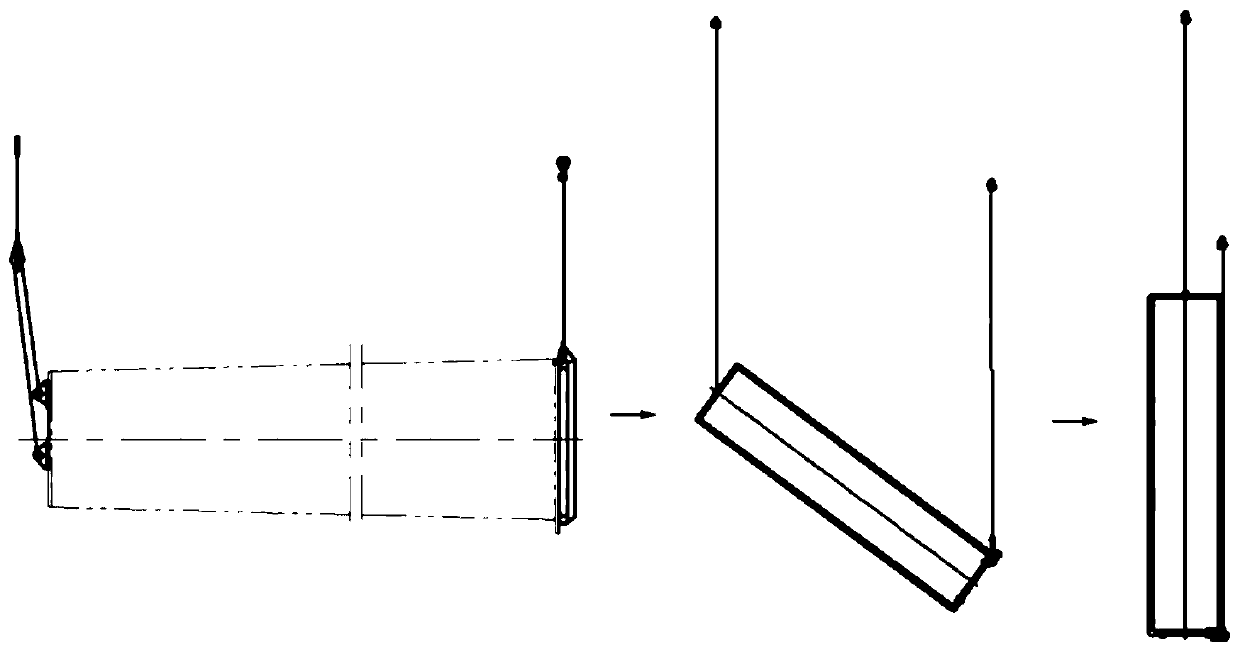

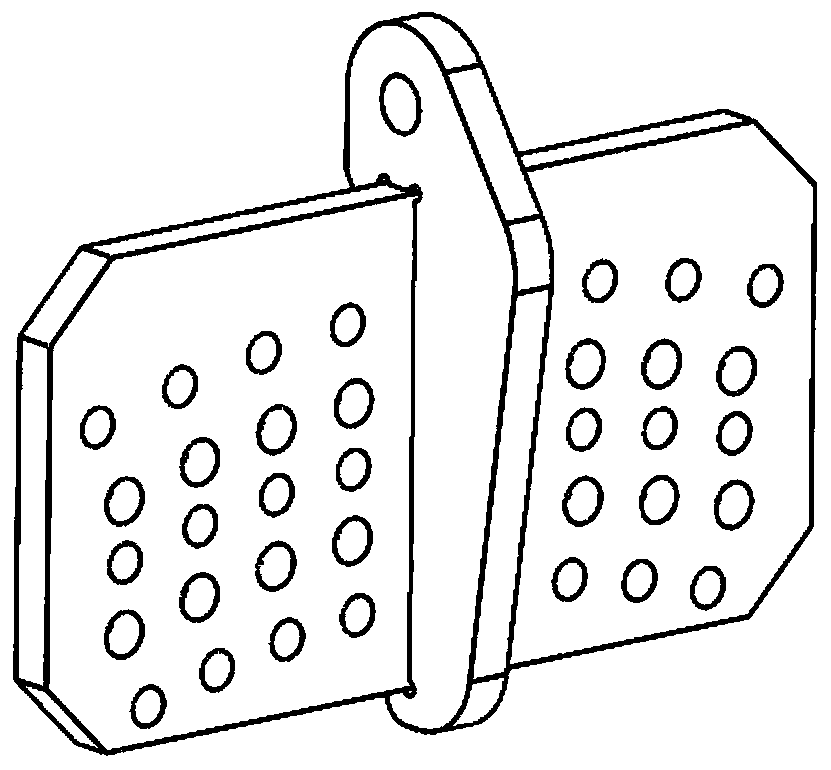

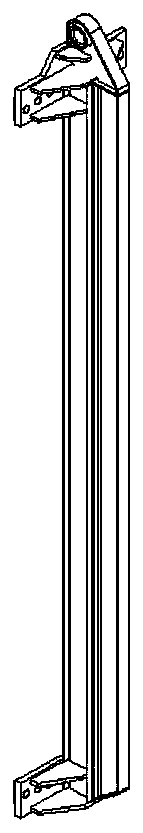

[0022] Such as Figure 4 to Figure 6 As shown, the wind power tower hoisting universal tail hanger described in this embodiment includes a fixed rod 1, an upper bending lever assembly 2, a strut 3, a lower lever assembly 4, a hook 5, an adjusting bolt 6 and a tower method Blue pressing plate 7, one side of the fixed rod 1 is formed with a groove-shaped support part 11 for supporting the wind power tower, and the width of the notch of the groove-shaped support part 11 is greater than the thickness of the tower flange, so that it can adapt to different The thickness of the tower flange, there are two adjusting bolts 6, through the two adjusting bolts 6 passing through the side wall of the groove-shaped support part 11 and touching the tower flange for fixing, at the same time, the two adjusting bolts 6 There is also a tower flange pressure plate 7 between the tower flange and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com