Permeable double-row retaining wall for urban buildings

A technology for retaining walls and buildings, applied in buildings, water conservancy projects, underwater structures, etc., can solve the problems of different design levels, affecting the durability of structures, affecting the stability of urban buildings, etc., to achieve enhanced anti-skid The effect of moving and anti-overturning ability, good structural mechanical performance, and good drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

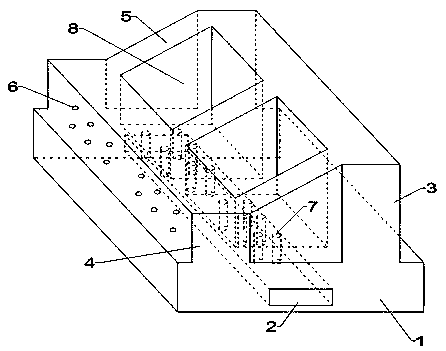

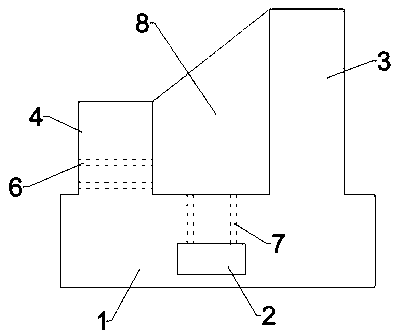

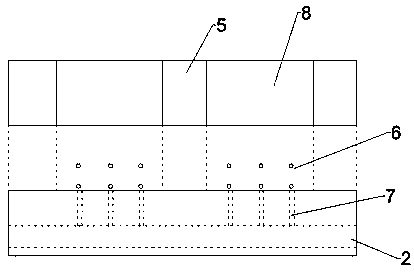

[0024] Example: such as Figure 1-6 As shown, a permeable double-row retaining wall for urban buildings includes a concrete base 1, a water pipe 2, a first row of concrete walls 3, a second row of concrete walls 4, reinforcing ribs 5, permeable holes 6, and grooves Inner permeable hole 7, hollow trapezoidal body 8, gravel backfill layer 9;

[0025] The inner bottom of the concrete base 1 is pre-embedded with a water pipe 2, the first row of concrete walls 3, the second row of concrete walls 4 are connected with the concrete base 1 arranged under the ground through built-in steel bars and are located on the concrete base 1 Above, the first row of concrete walls 3 and the second row of concrete walls 4 are connected by reinforcing ribs 5 to form a hollow trapezoidal body 8, which is filled with crushed stone backfill layer 9, and hollow trapezoidal body 8 The bottom is provided with multiple rows of permeable holes 7 in the groove, and the multiple rows of permeable holes 7 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com