Non-contact detection method for roundness of cylindrical roller

A technology of cylindrical rollers and detection methods, applied in measuring devices, instruments, optical devices, etc., can solve the problems of affecting the accuracy of measurement, inability to precisely control equal pressures, and errors in measurement results, and achieve fast data measurement speed, The effect of simple calculation process and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods (embodiments), but it is not used as a basis for limiting the present invention.

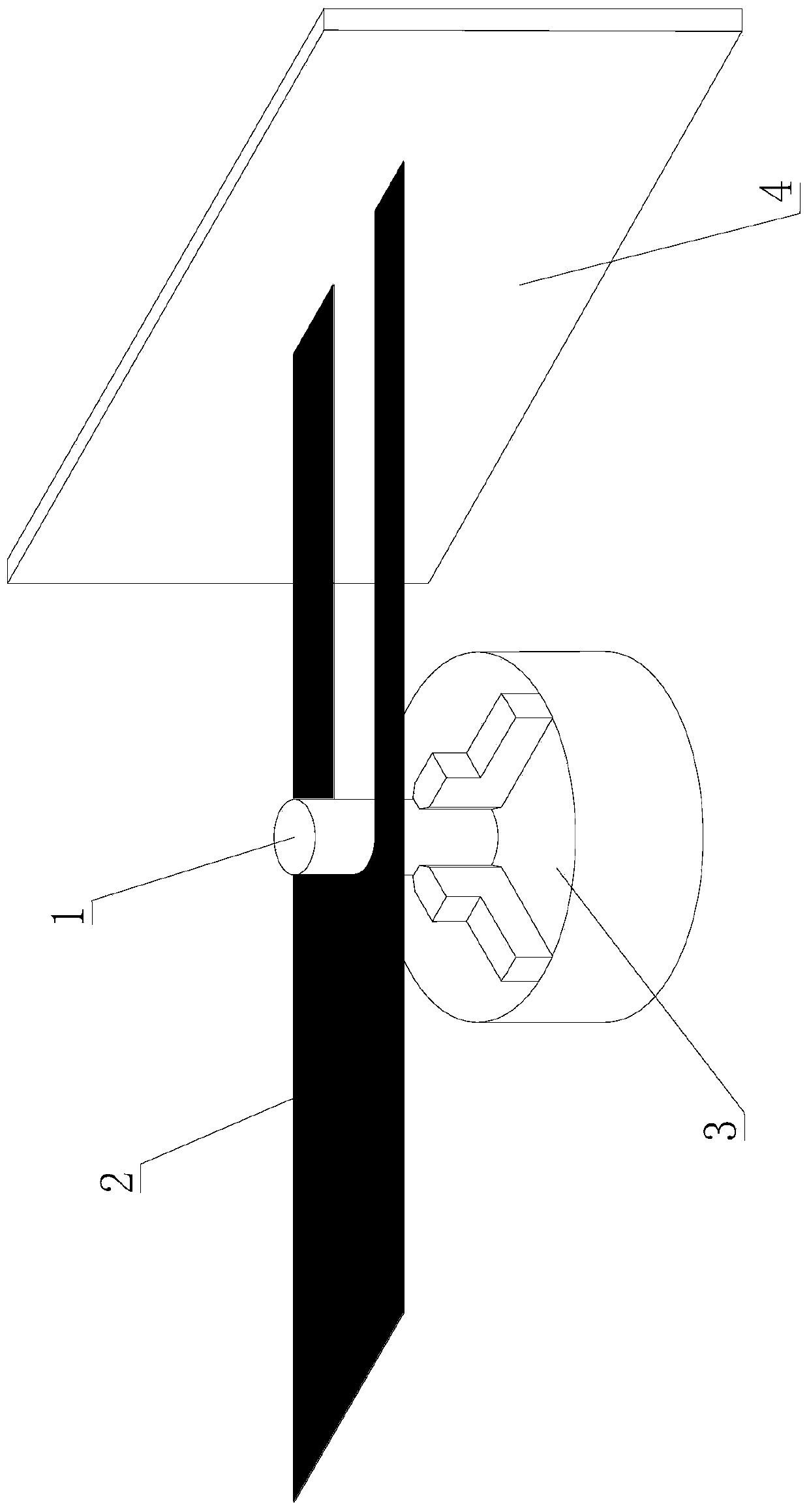

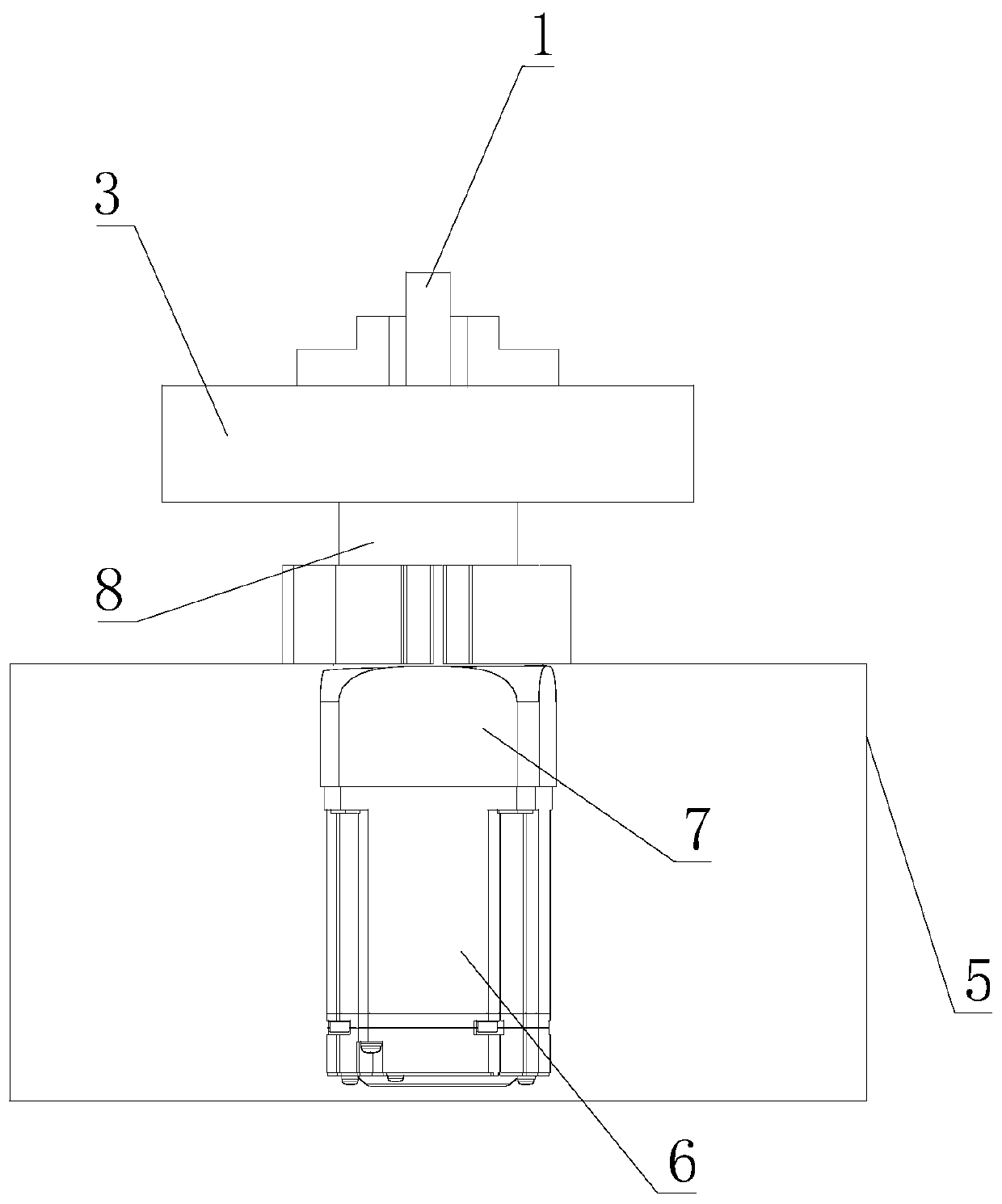

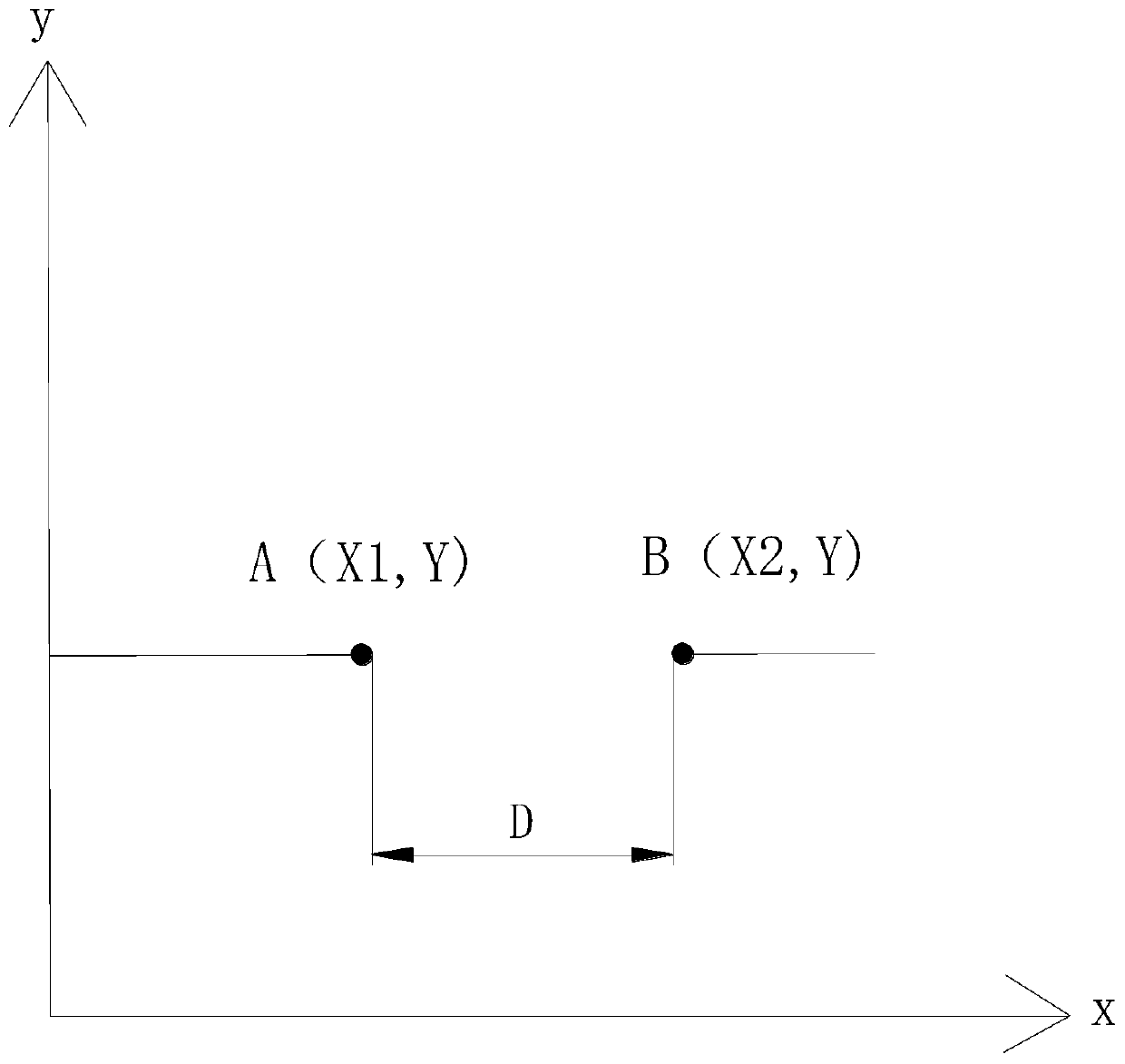

[0019] Such as Figure 1-3 As shown, the non-contact detection method of cylindrical roller roundness, the measurement environment is a dark room; when measuring, the cylindrical roller 1 is vertically placed in the fixture of the vertical machine tool for fixing, and the fixture is driven by the spindle of the machine tool to rotate so that it is fixed on the The cylindrical roller 1 on the fixture rotates at a fixed axis at a constant speed; a projection board 4 is provided on one side of the machine tool, and a photosensitive element is arranged in the projection board 4, and the photosensitive element is electrically connected with the computer; The light source emits horizontal parallel light 2 to irradiate the cylindrical roller 1, and the parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com