A flexible multi-parameter sensor based on the principle of fiber grating and its preparation

A fiber grating and sensor technology, applied in the sensor field, can solve problems such as inability to meet multi-parameter measurement, unsuitable for human body surface data detection, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

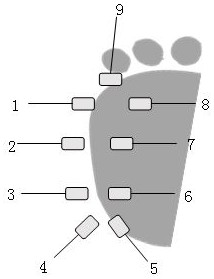

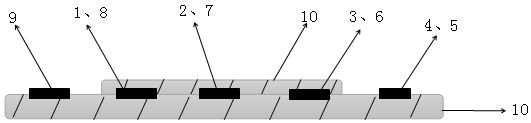

[0019] The following describes the embodiments of the present invention in detail, and the embodiments take the temperature, pressure, humidity parameters of the soles of the feet and the sensor distribution structure as examples. Examples of embodiments are shown in the drawings, wherein the same or similar symbols represent the same or similar elements or elements having the same or similar functions throughout.

[0020] An embodiment of a flexible multi-parameter sensor based on the fiber grating principle provided by the present invention is as follows figure 1 As shown, it is specifically: the sensor includes nine bare fiber Bragg gratings used as the main body and the PDMS film used as the outer packaging layer, wherein the main body part mainly includes the first temperature grating 1, the second temperature grating 2, the third temperature grating No. 3 temperature grating, No. 1 humidity grating 4, No. 2 humidity grating 5, No. 1 pressure grating 6, No. 2 pressure gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com