Online optimization method for thermoelectric load distribution of multiple heat supply units of thermal power plant cluster

A heating unit and load distribution technology, which is applied in the direction of instruments, data processing applications, forecasting, etc., can solve the problems of not considering the economic impact of thermal and electrical load changes, and no steam optimization, etc., to improve calculation speed and accuracy, reduce total energy consumption, achieve precise definition and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

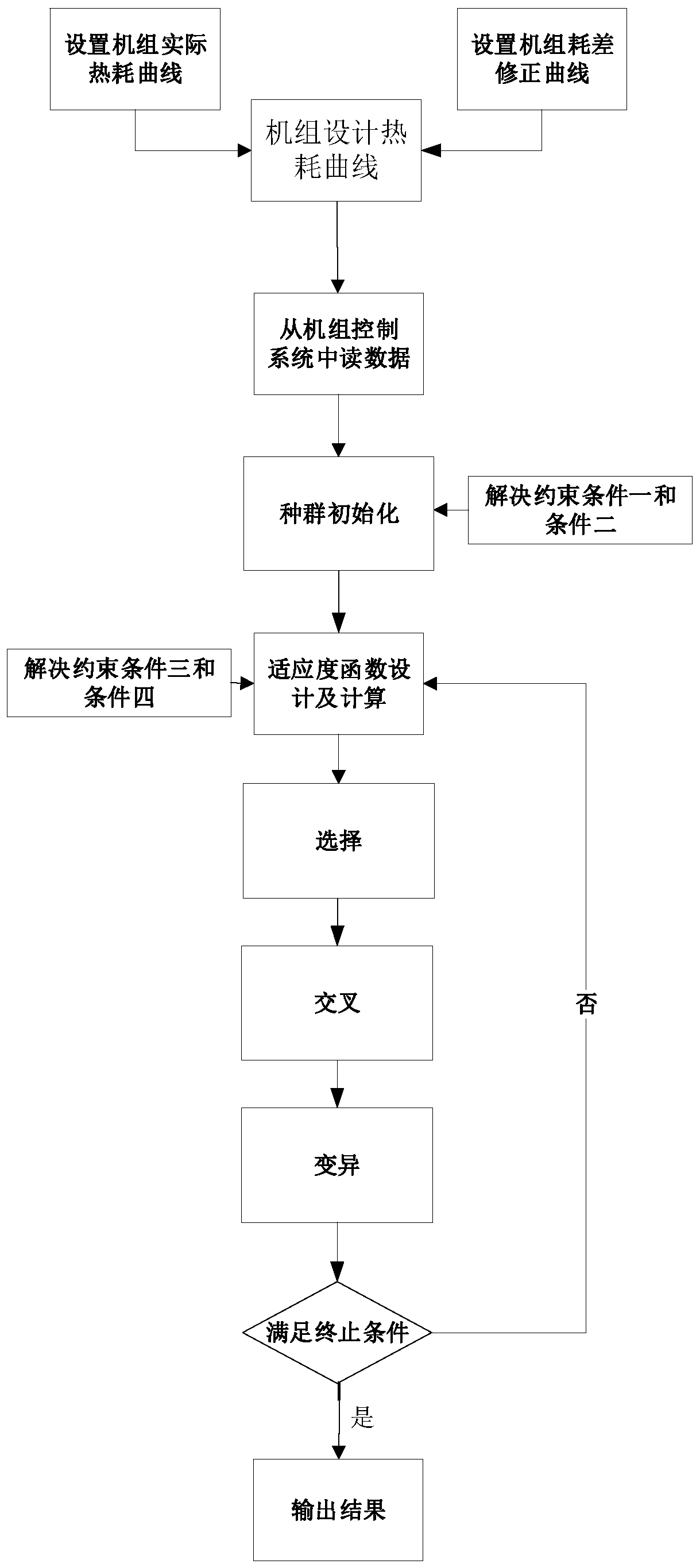

[0014] Specific implementation mode one: as figure 1 As shown, the online optimization method for thermal power load distribution of multiple heating units in a thermal power plant fleet described in this embodiment includes the following steps:

[0015] Step 1. Obtain the actual heat consumption curve of each heating unit in the n heating units according to the test, and then correct the total coefficient θ according to the consumption difference of each heating unit i Correct the actual heat consumption curve to obtain the design heat consumption curve of the unit; where: i=1,2,...,n;

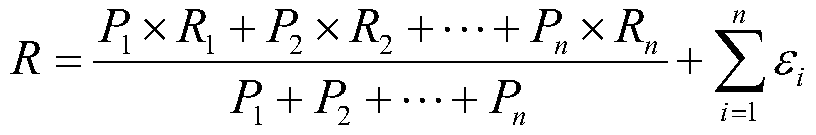

[0016] Step 2. According to the heat consumption value R corresponding to each heating unit in the design heat consumption curve of the unit i , to set the objective function for optimizing the heat and electricity load distribution of the heating unit;

[0017] Step 3, setting the constraint conditions of the objective function of step 2;

[0018] Step 4. According to the objective functi...

specific Embodiment approach 2

[0020] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the specific process of the step one is:

[0021] According to the test, the actual heat consumption curve of each heating unit in the n heating units is obtained. The actual heat consumption curve refers to: with the power P of the i-th heating unit i and the extraction steam quantity Q of m different steam extraction positions of the i-th heating unit i1 ,...,Q im As an independent variable, take the heat consumption value R of the i-th heating unit i is a family of curves for the dependent variable;

[0022] Correct the total coefficient θ by using the consumption difference of each heating unit i The actual heat consumption curve is corrected to obtain the unit design heat consumption curve, which is expressed as:

[0023] The first heating unit: R 1 = θ 1 ·f(P 1 ,Q 11 ,...,Q 1m );

[0024] The second heating unit: R 2 = θ 2 ·f(P 2 ...

specific Embodiment approach 3

[0028] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: the total coefficient θ of the consumption difference correction of each heating unit i It is determined according to the deviation from the design value of the six factors of condenser back pressure, main steam pressure, main steam temperature, reheat pressure, reheat steam temperature and feed water temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com