SAB safety airbag size visual measurement method

An airbag and visual measurement technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of manual detection, limited operator physical condition, working state, limited production efficiency, product quality, and high labor intensity, etc., to achieve Realize the effects of multi-station detection, small amount of data and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

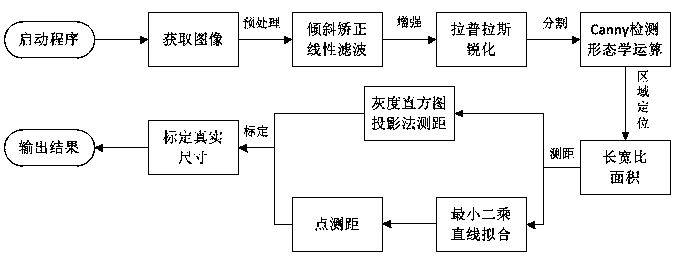

[0065] Please refer to figure 1 , the present invention provides a kind of SAB safety airbag size visual measurement method, specifically comprises the following steps:

[0066] Step S1: Build a machine vision system to collect optical images of the SAB airbag;

[0067] In this embodiment, the machine vision system for collecting images includes industrial cameras and lenses, lighting sources, conveyor belts and controllers. The controller is connected with the industrial camera and the motor that controls the movement of the conveyor belt, and is used to receive the optical image collected by the industrial camera; the controller is connected with the host computer, transmits the optical image to the host computer and receives the control command of the host computer, Used to control the operation of the conveyor belt.

[0068] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com