A cathode heating subassembly and its manufacturing method

A heat sub-cathode technology, applied in the field of microwave vacuum electronic devices, can solve problems such as difficult assembly, poor product consistency, and low difficulty in process implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

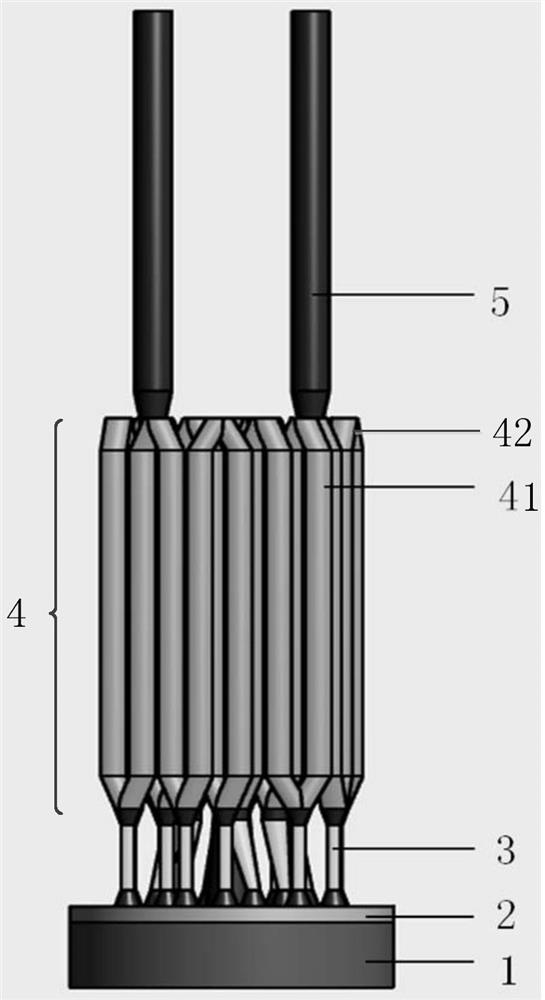

[0060] A manufacturing method of a cathode heating subassembly:

[0061] Input the 3D model file into the SLM equipment for layered and discrete data processing, and irradiate the molten tungsten powder with laser to accumulate accurately from bottom to top:

[0062] The bottom layer is the porous emitter 1 of the cathode emitter, and the density is controlled at about 75% of the theoretical density of pure tungsten, and then a dense layer 2 is piled up on it, and the density reaches more than 90% of the theoretical density of pure tungsten;

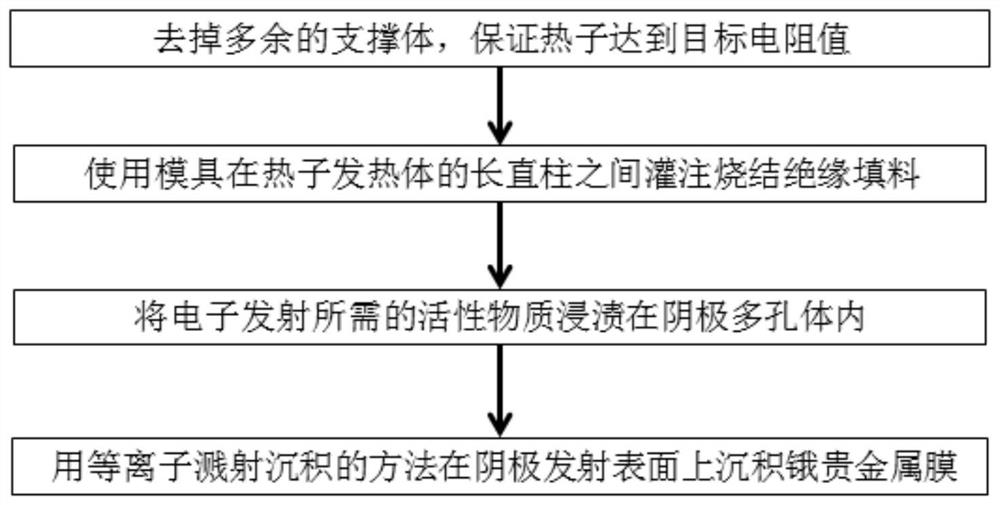

[0063] Continue to pile up the support body 3, the support body 3 is an array of slanted columns and straight columns, which are directly accumulated and grown on the dense layer 2; the top surface of each column of the support body 3 is divided into two short slanted columns, and continue to pile up to form heat particles The column array of the heating element 4, the top of each column is fused with the adjacent column through oblique ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com