Self-maintenance lightning arrester grounding device

A technology of grounding device and arrester is applied in the maintenance of parts of connecting device, coupling device, line connector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

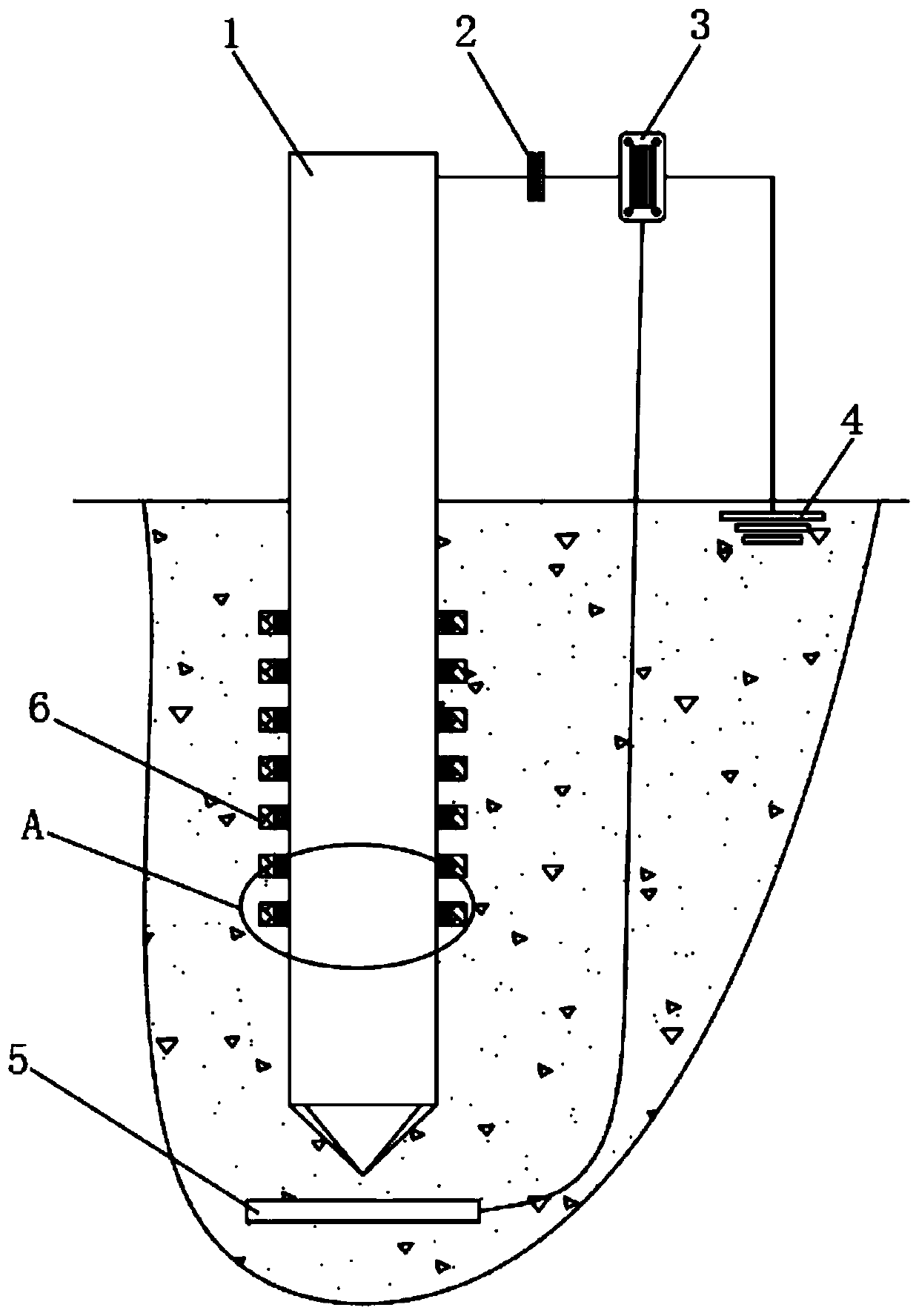

[0023] refer to Figure 1-2 , a grounding device for a self-maintaining lightning arrester, comprising a grounding rod 1, a capacitor plate 2, an electromagnetic relay 3, and a grounding plate 4 inserted on the ground surface, and the grounding rod 1, capacitor plate 2, electromagnetic relay 3, and grounding plate 4 are sequentially connected in series. On the circuit, the grounding piece 4 is grounded, and the part of the grounding rod 1 inserted in the ground is provided with a derusting device; the grounding piece 4 is a metal sheet made of simple chromium, and the cost of simple chromium is relatively high, so only a small amount of chromium is used here. There will be no significant cost increase.

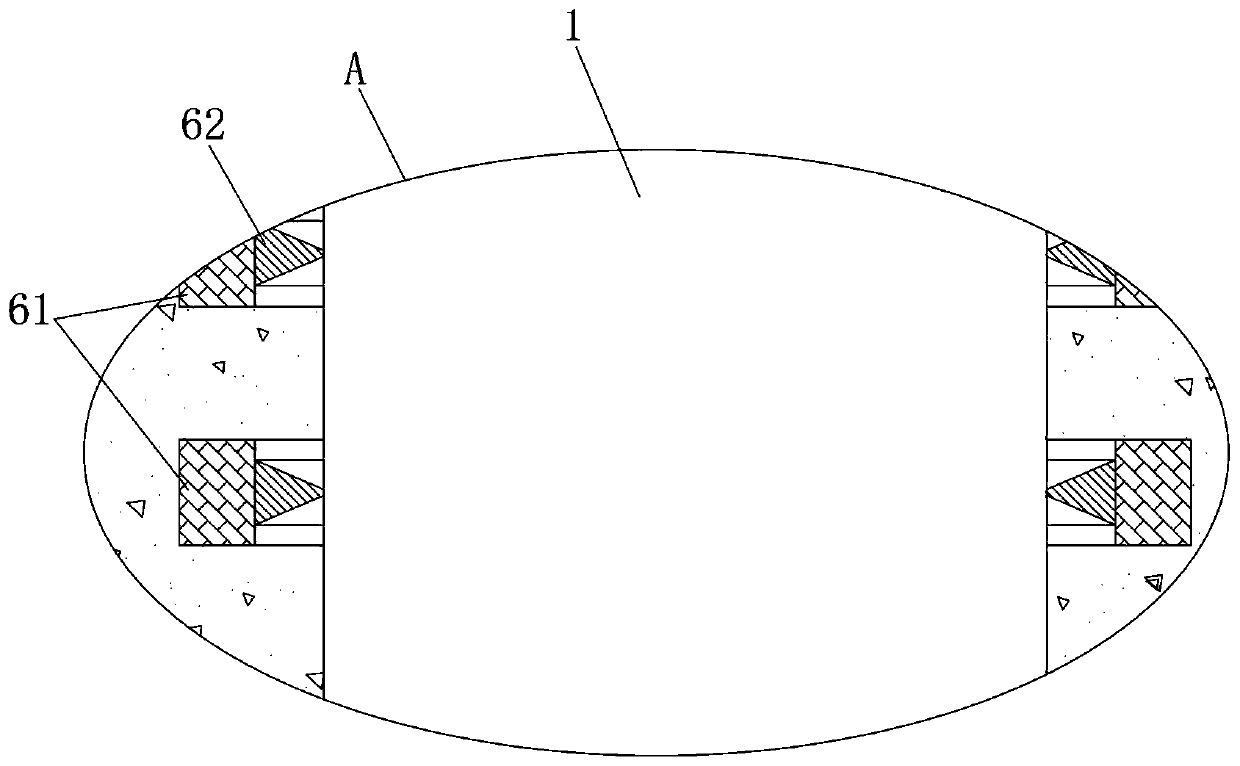

[0024] The derusting device comprises an electromagnet 5 and a plurality of annular scraper groups 6, each annular scraper group 6 includes an annular permanent magnet 61 and a first scraper ring 62, and the first scraper ring 62 is glued and fixed in the annular permanent mag...

Embodiment 2

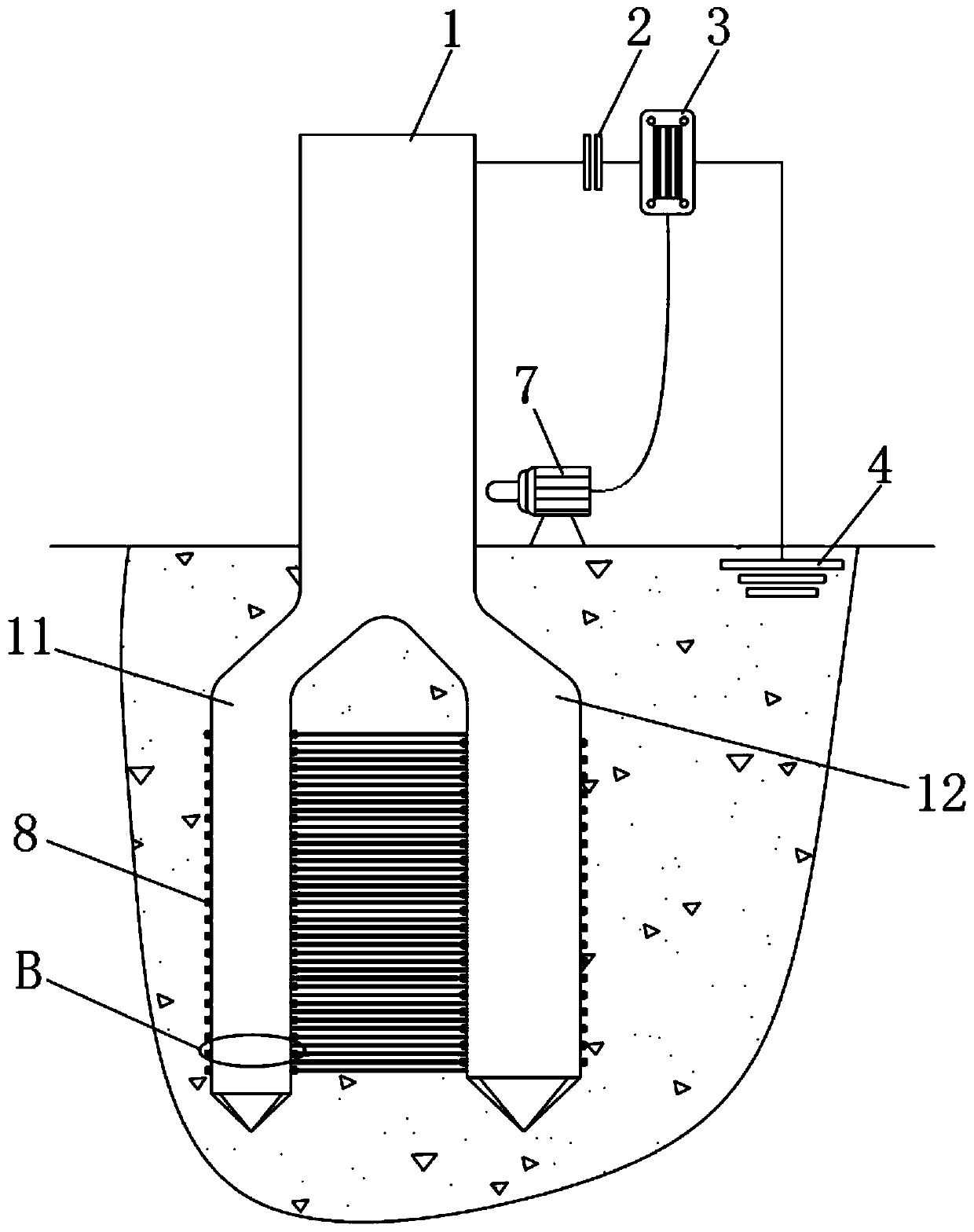

[0029] refer to Figure 3-4 The difference between this embodiment and Embodiment 1 is that the derusting device includes a telescopic motor 7 and a plurality of interactive scraping groups 8, and the part of the ground rod 1 inserted on the ground surface is bifurcated into thin rods 11 and thick rods 12 in a herringbone shape. , each interactive scraping group 8 includes a fixed rod 81 and a second scraper ring 82, several fixed rods 81 are welded equidistantly on the thin rod 11 and the thick rod 12, and each thin rod 11 and the thick rod 12 slide A plurality of second scraper rings 82 are socketed, and the fixed rod 81 on each thin rod 11 is welded to the second scraper ring 82 on the thick rod 12 in one-to-one correspondence, and the fixed rod 81 on each thick rod 12 is connected to the thin rod 11 The second scraper ring 82 on the top is welded one by one, the telescopic motor 7 is fixedly arranged on the ground surface and the output end is opposite to the ground rod 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com