Combined low voltage ride-through control system, low voltage ride-through reactive power compensation method and de-excitation control method

A low-voltage ride-through and control system technology, applied in the direction of reactive power adjustment/elimination/compensation, flexible AC transmission system, wind power generation, etc., can solve problems such as reactive power demand, DC side energy accumulation, etc., to solve energy accumulation problems, The effect of solving the problem of low voltage ride through, improving reliability and demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

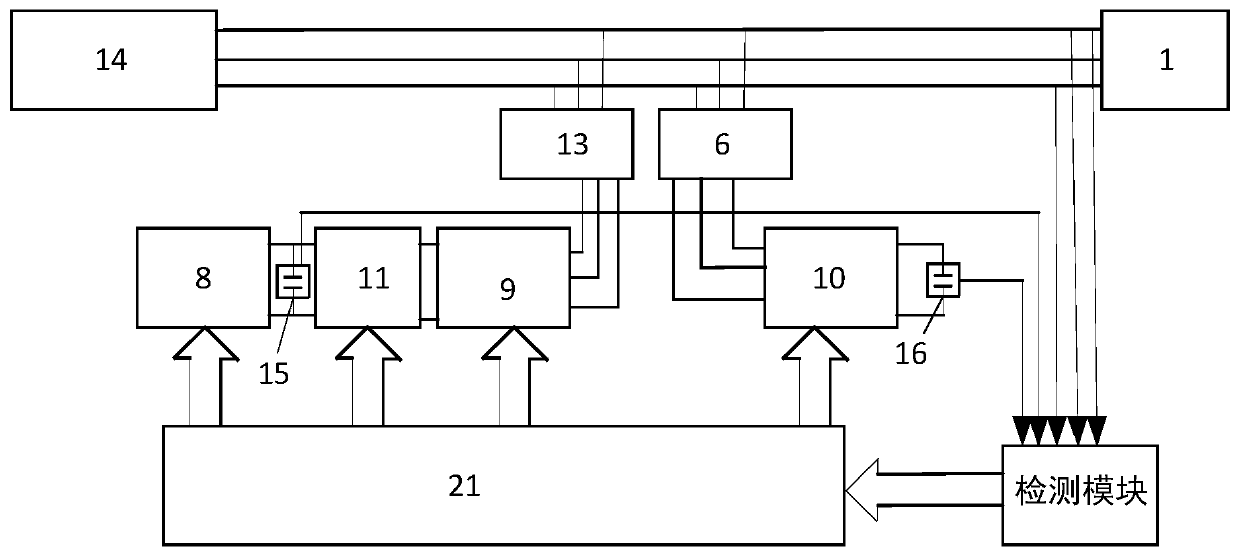

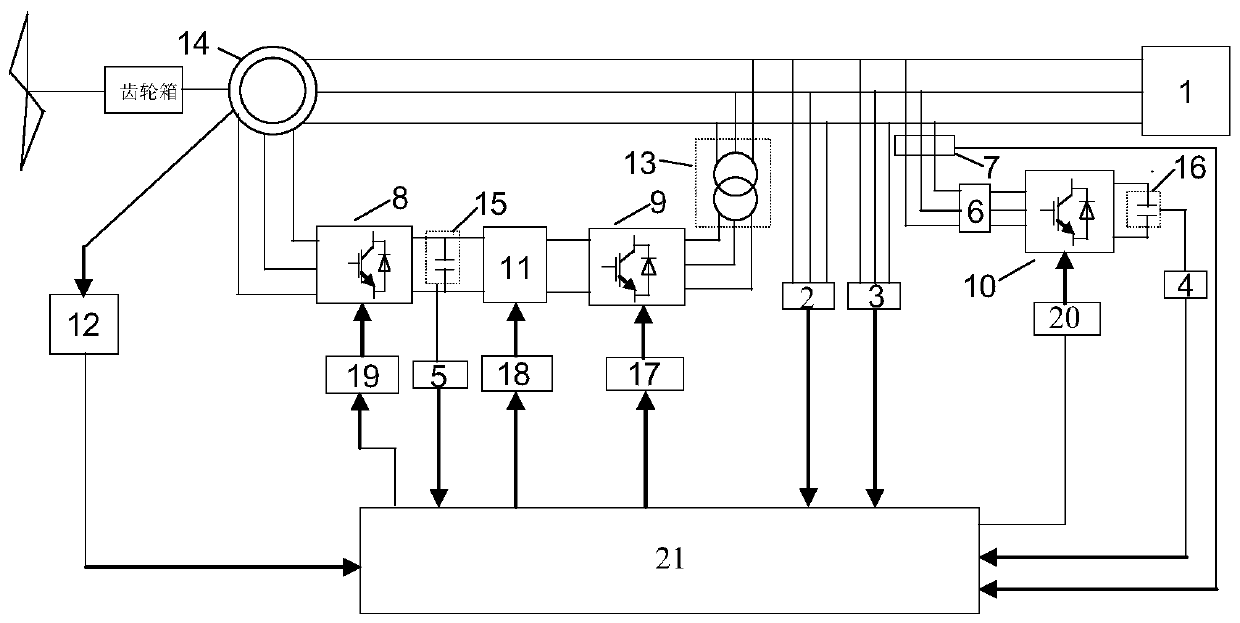

[0055] A combined low-voltage ride-through control system, such as figure 1 As shown, it includes three-phase power grid 1, reactor 6, rotor-side converter 8, grid-side converter 9, STATCOM main circuit 10, DC side unloading circuit 11, grid-side transformer 13, double-fed induction motor 14, second A DC capacitor 15, a first DC capacitor 16, and a main control module 21; the STATCOM main circuit 10 is a static synchronous compensator, and the three-phase grid 1 is connected to a reactor 6, a grid-side transformer 13, a double-fed induction motor 14, and The detection module is connected, the reactor 6 is connected with the STATCOM main circuit 10, and the STATCOM main circuit 10 is respectively connected with the first DC capacitor 16 and the main control module 21, and the first DC capacitor 16 is connected with the detection module, and the The detection module is connected to the second DC capacitor 15, the output end of the detection module is connected to the main contro...

Embodiment approach 1

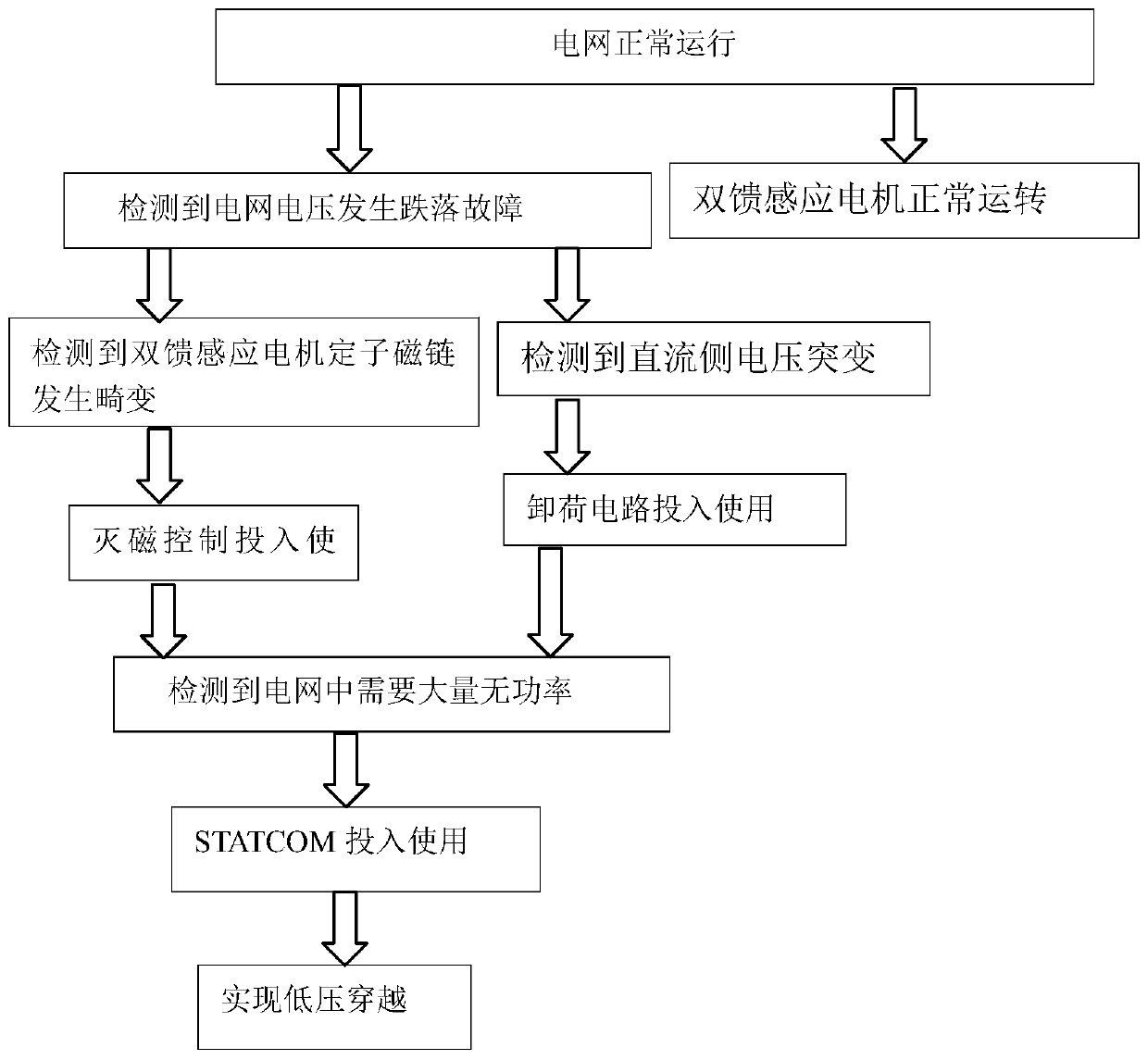

[0064] A low-voltage ride-through reactive power compensation method based on the combined low-voltage ride-through control system described in the first embodiment, such as image 3 shown, including the following steps:

[0065] Step a1, the three-phase grid 1 is powered on, and the three-phase grid 1 operates normally;

[0066] Step a2, judge in real time whether the voltage drop of the three-phase grid 1 has a fault, if not, the doubly-fed induction motor 14 operates normally, and continue to execute step a2; if so, execute step a3;

[0067] Step a3, respectively collecting the current and voltage of the three-phase grid 1 when a fault occurs through the detection module; detecting whether the stator flux linkage of the doubly-fed induction motor 14 is distorted, and whether the DC side voltage has a sudden change;

[0068] Step a4: Send the voltage and current at the time of the fault to the main control module 21 for processing and demagnetization control processing. Aft...

specific Embodiment approach 3

[0072] A specific method based on the demagnetization control process described in the second step a4 of the specific embodiment, such as Figure 4 to Figure 8 shown, including the following steps:

[0073] Step b1, according to the working principle of the doubly-fed induction motor 14, the basic equation of the voltage flux linkage of the rotor and the stator is obtained, as follows:

[0074]

[0075] where u s and u r are stator voltage and rotor voltage respectively, R s and R r Indicates the stator and rotor resistance, ψ s and ψ r are stator flux linkage and rotor flux linkage respectively, i s and i r Expressed as stator current and rotor current, L s and L r are stator inductance and rotor inductance respectively, L m for mutual inductance;

[0076] Step b2, carry out Parker transformation to formula (1), and convert it to the equation under the synchronously rotating dq coordinate system, as follows:

[0077]

[0078] where u sq , u sd i sq i sd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com