Method for removing protruding block defects on polysilicon surface by slow grinding and semiconductor process method

A polysilicon and semiconductor technology, applied in semiconductor/solid-state device manufacturing, grinding equipment, grinding machine tools, etc., can solve the problems of excessive removal, fast removal rate, and affecting the performance of device structures, etc., achieve high cleaning effect, reduce loss, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

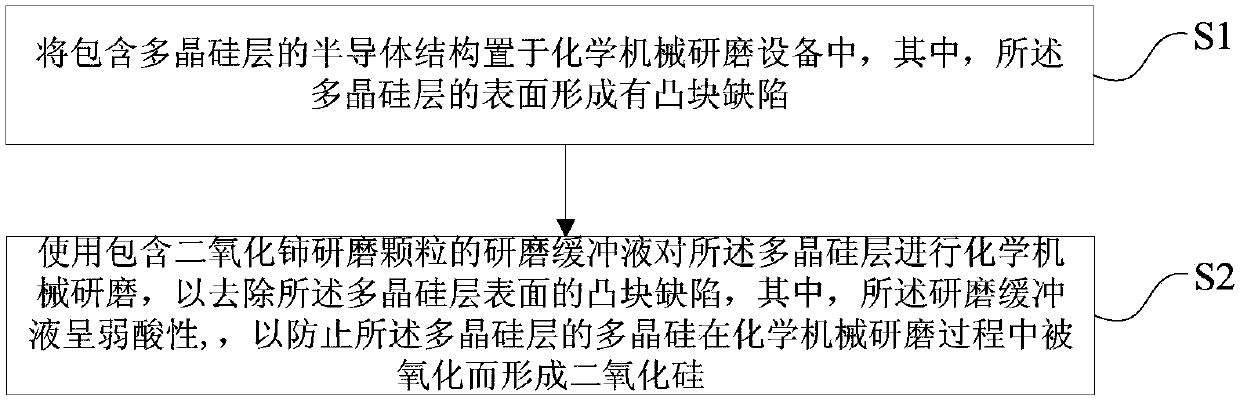

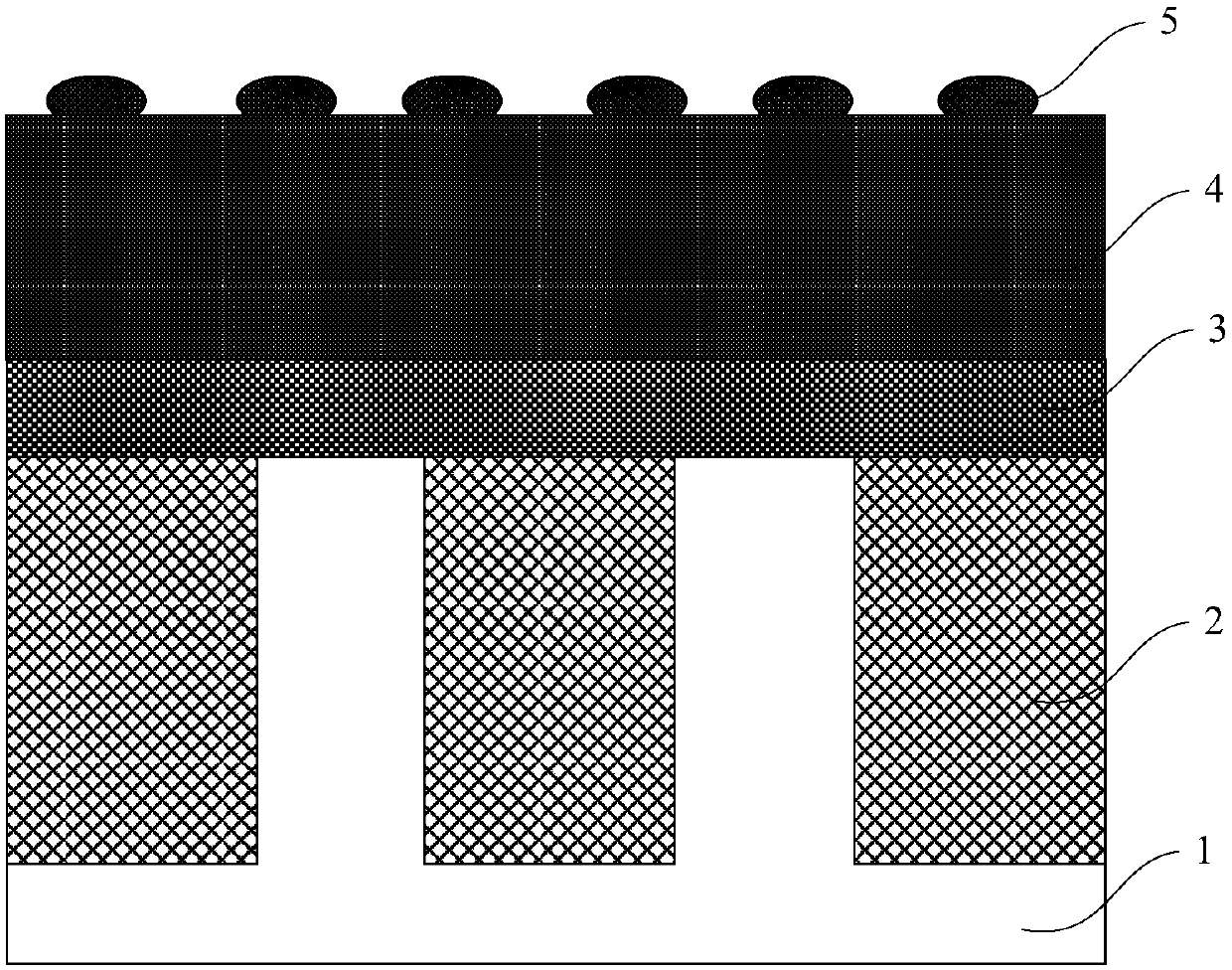

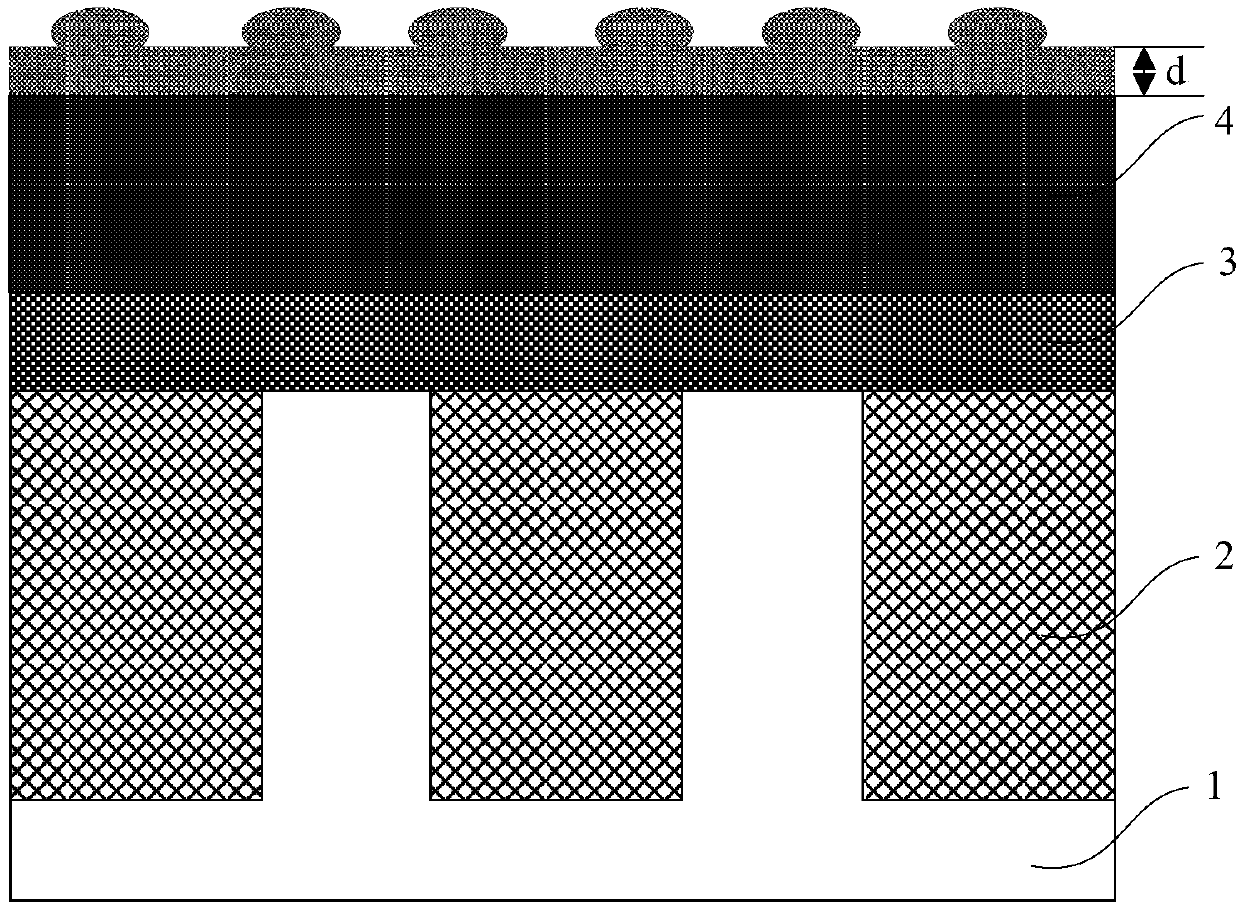

[0046] Such as Figure 1 to Figure 3 shown. The present invention provides a method for removing bump defects on the surface of polysilicon by slow grinding. The method for removing bump defects on the surface of polysilicon by slow grinding at least includes the following steps:

[0047] 1) placing a semiconductor structure comprising a polysilicon layer having bump defects formed on a surface of the polysilicon layer in a chemical mechanical polishing apparatus; and,

[0048] 2) Carrying out chemical mechanical grinding on the polysilicon layer with a grinding buffer containing cerium oxide abrasive particles to remove bump defects on the surface of the polysilicon layer, wherein the grinding buffer is weakly acidic to prevent the The polysilicon of the polysilicon layer is oxidized to form silicon dioxide during chemical mechanical polishing.

[0049] In step 1), see figure 2 Step S1 in and figure 2 , placing the semiconductor structure including the polysilicon layer...

Embodiment 2

[0069] see Figure 4 , the present invention also provides a semiconductor process method, the semiconductor process method comprising the following steps:

[0070] Step S10: preparing a semiconductor structure comprising a polysilicon layer having bump defects formed on the surface of the polysilicon layer; and,

[0071] Step S20: Treat the surface of the polysilicon layer of the semiconductor structure by using the slow grinding method described in the first embodiment to remove bump defects on the polysilicon surface.

[0072] In step S10, see Figure 4 , preparing a semiconductor structure comprising a polysilicon layer, the surface of the polysilicon layer is formed with bump defects.

[0073] As an example, the semiconductor structure may be any existing structure containing the polysilicon layer, specifically, the semiconductor structure may be any existing semiconductor structure in which a polysilicon layer has just been formed, the The underlying polysilicon layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com