Aircraft movable airfoil adjustment detection system and method

A detection system and movable wing technology, which is applied in the field of adjustment and detection systems for movable airfoils, can solve problems such as affecting aircraft production and manufacturing progress, relying on manual operation experience, increasing aircraft manufacturing costs, etc., and achieves safe and reliable testing, high degree of automation, Simple and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

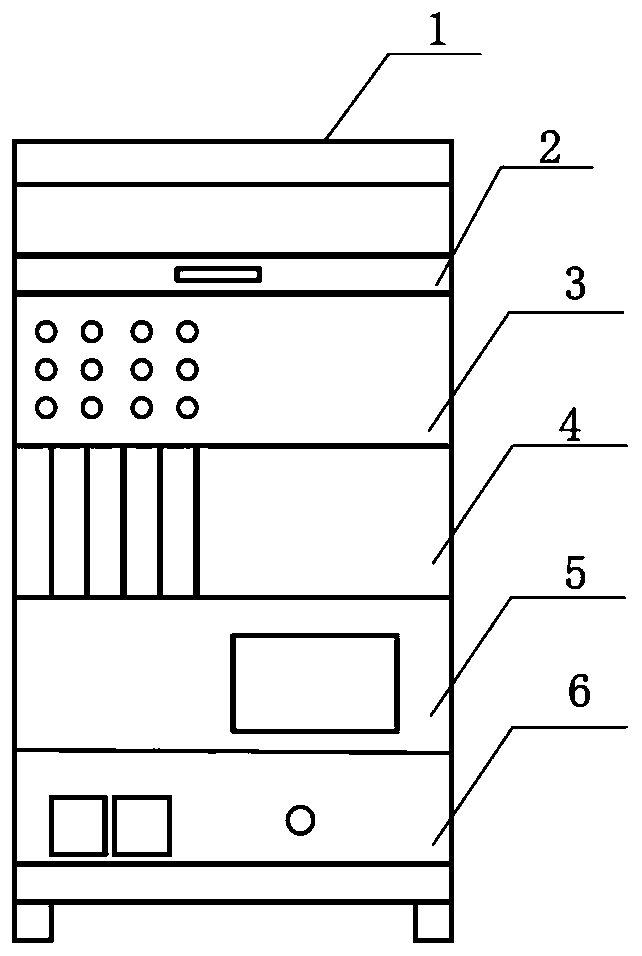

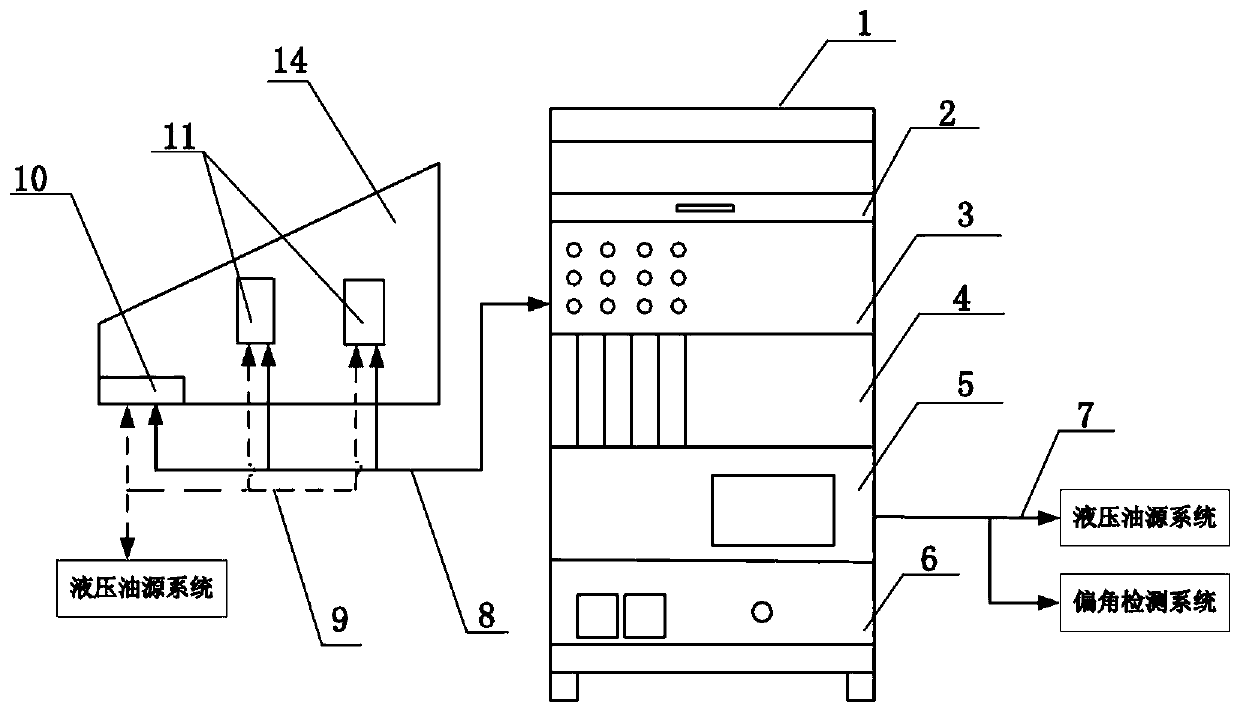

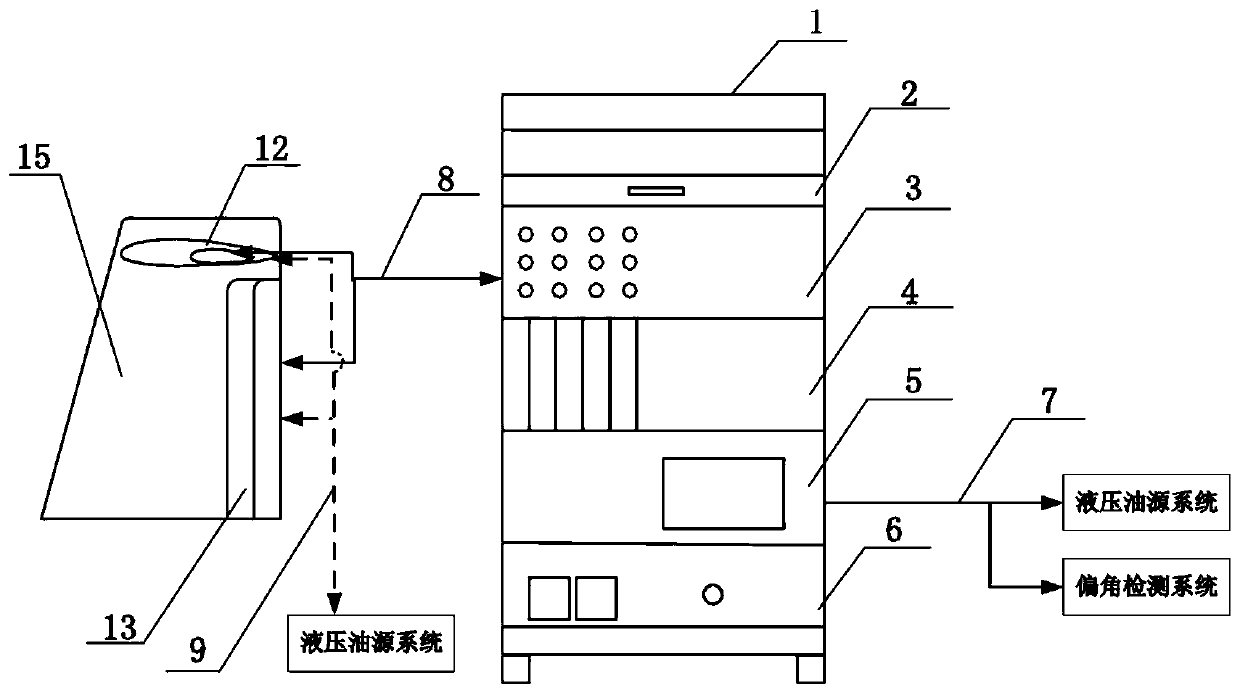

[0027] Such as figure 1 As shown in -3, the aircraft movable wing surface adjustment detection system 1 includes a signal conditioning box 3, a card insertion box 4, an integrated control computer 5, a program-controlled power supply 6, a display 2 and supporting cables 8.

[0028] The rear panel of the signal conditioning box 3 is distributed with an array of sockets, and the signal cross-linking and adaptation are performed between the airfoil actuators, the rudder surface position sensor, the card insertion box 4, and the integrated control computer 5 through the supporting cables 8, Each socket is designed as an error-proof socket and made with a silk screen mark. The front panel of the signal conditioning box 3 is distributed with an array of disconnection blocks, and the inside of the signal conditioning box is provided with a core wire harness, which leads the signal from the rear panel to the disconnection block on the front panel. The block is convenient for fault loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com